Oil return device and control method thereof

A control method and control unit technology, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as ineffectiveness, and achieve the effect of reducing the probability of startup failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

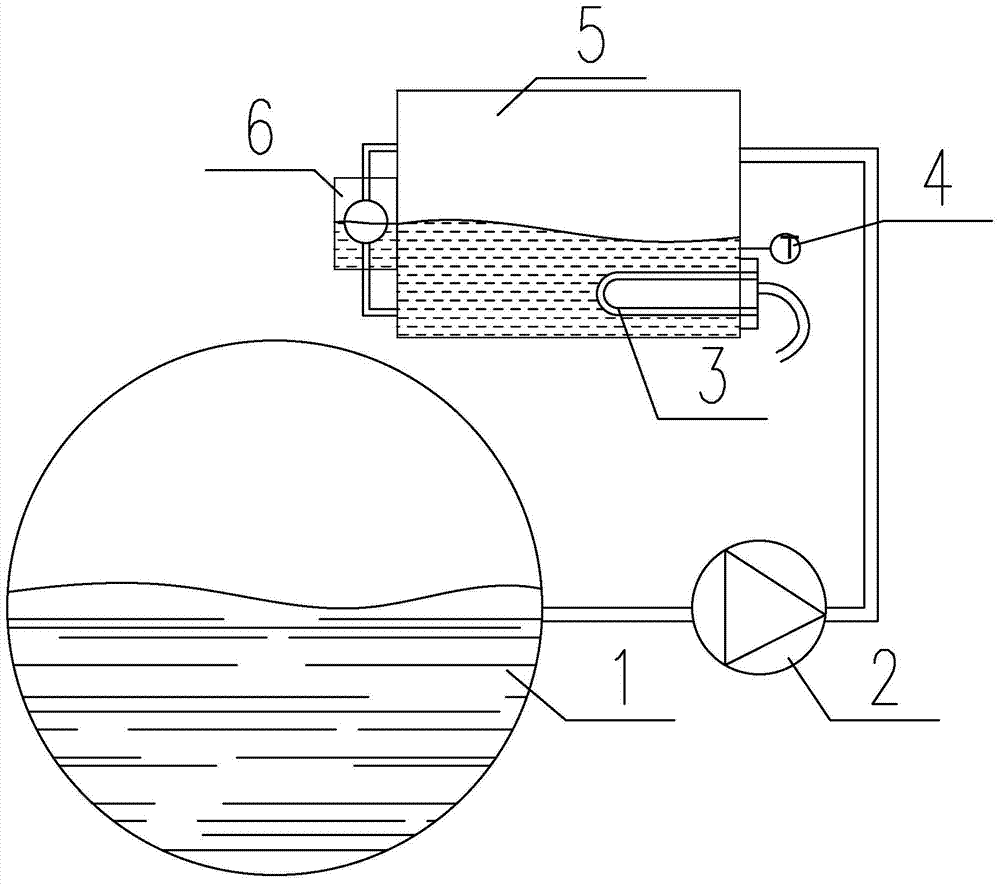

[0035] Such as figure 1 As shown, the oil return device is usually used in chillers, especially centrifugal chillers. It includes a refrigerant heat exchanger 1, an oil tank 5, a pump 2 and a control unit (not shown in the figure). The input end of the pump 2 is connected with the refrigerant heat exchanger 1, and the output end is connected with the oil tank 5; the oil tank 5 is used for storing the lubricating oil of the chiller. The oil tank 5 is provided with an oil heater 3 for heating the lubricating oil in the oil tank 5, an oil temperature sensor 4 for detecting the oil temperature T of the lubricating oil in the oil tank 5, and an oil temperature sensor 4 for detecting the oil temperature T of the lubricating oil in the oil tank 5. The liquid level sensor 6 that detects the liquid level height H; The liquid level sensor 6 preferably adopts a liquid level switch; The pump 2, the liquid level sensor 6, the oil heater 3, and the oil temperature sensor 4 are connected wi...

Embodiment approach 2

[0062] In this embodiment, on the basis of the solution in Embodiment 1, the liquid level switch is used as the liquid level sensor to detect the liquid level height, and at the same time, the liquid level switch is used as the control unit of the pump 2 to control the opening of the pump 2 ; The liquid level switch also sends a switch signal to the control unit of the oil heater 3 to control the oil heater 3 . As a preferred embodiment, the liquid level switch has a plurality of floats at different water levels, and each float provides water level signals indicating different water levels, wherein the signals of different water levels correspond to different voltage signals. The specific control method will be described below taking H1=H2 as an example, that is, when the water level changes near H1, the liquid level switch will simultaneously control the pump 2 and the oil heater 3 to change their working states. When the water chiller is ready to start up, firstly the oil he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com