Vibration detection method based on laser wavefront coding technique

A coding technology, vibration detection technology, applied in measuring devices, using wave/particle radiation, measuring ultrasonic/sonic/infrasonic waves, etc. Detect problems such as application range, inconvenient integration of piezoelectric vibration sensors, etc., to achieve the effect of easy expansion of functions, high reliability, and easy integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

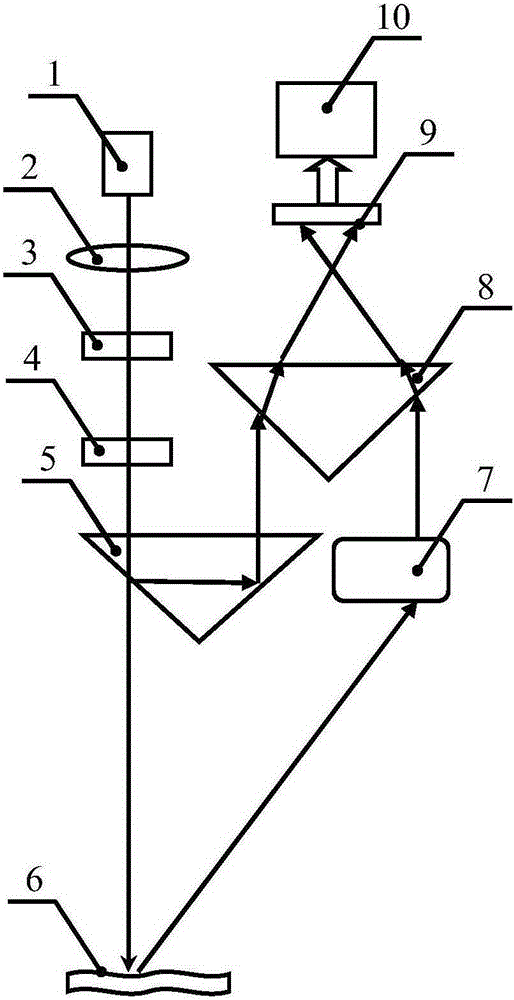

[0028] Such as figure 1 As shown, an embodiment of a vibration detection method based on laser wavefront coding technology, based on the laser astigmatism field phase interference behavior, combined with the principle of laser wavefront coding, using dynamic wavefront polarization and phase coding, after coding, the light field splits and returns The reference beam, and the forward test beam, the test beam is projected onto the vibrating object to be detected, and the light field of the speckle part passes through the defocused imaging component to form an information beam carrying coded information and vibration information of the object, and the information beam and the reference beam Overlapping interference forms an interference field. The photoelectric sensor is set in the interference area to realize photoelectric transmission. The vibration analysis unit processe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com