Shale gas reservoir gas diffusion coefficient experiment test method

A technology of gas diffusion and shale gas reservoirs, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of small scale, difficult to popularize, complex and expensive instruments and equipment, etc., and achieve the effect of eliminating the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further illustrated below according to examples.

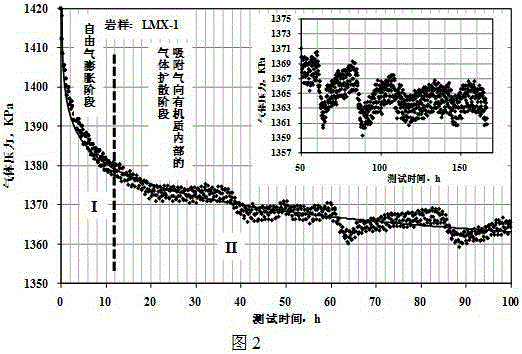

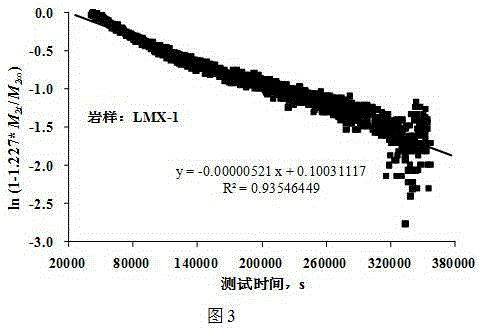

[0021] A shale plug rock sample of the Longmaxi Formation in the Sichuan Basin was selected, and the diffusion coefficient of gas (methane) in the shale was tested by the method of the present invention. Specific steps are as follows:

[0022] Step 1. Prepare the plunger shale rock sample (LMX-1) according to the SYT5358-2010 rock sample preparation method; first use nitrogen gas to drill and cut the shale rock sample with a diameter of 2.52 cm and a length of 3.93 cm, and then put 60 ℃ oven, weighing once every 24 hours, until the change of two adjacent weighings is less than 1.0% of the sample mass, it is considered that the rock sample is fully dried; the porosity of the rock sample after drying is 4.06% tested by CMS300;

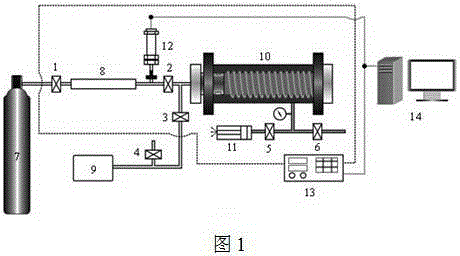

[0023] Step 2. Put the steel rock sample (with zero porosity) into the core holder, apply a certain confining pressure, and turn on the constant temperature control syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com