Microstrip reflective array unit loaded with cross slot on ground, and reflective array antenna

A cross-shaped, reflective array technology, applied to antennas, electrical components, circuits, etc., can solve problems such as limiting the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

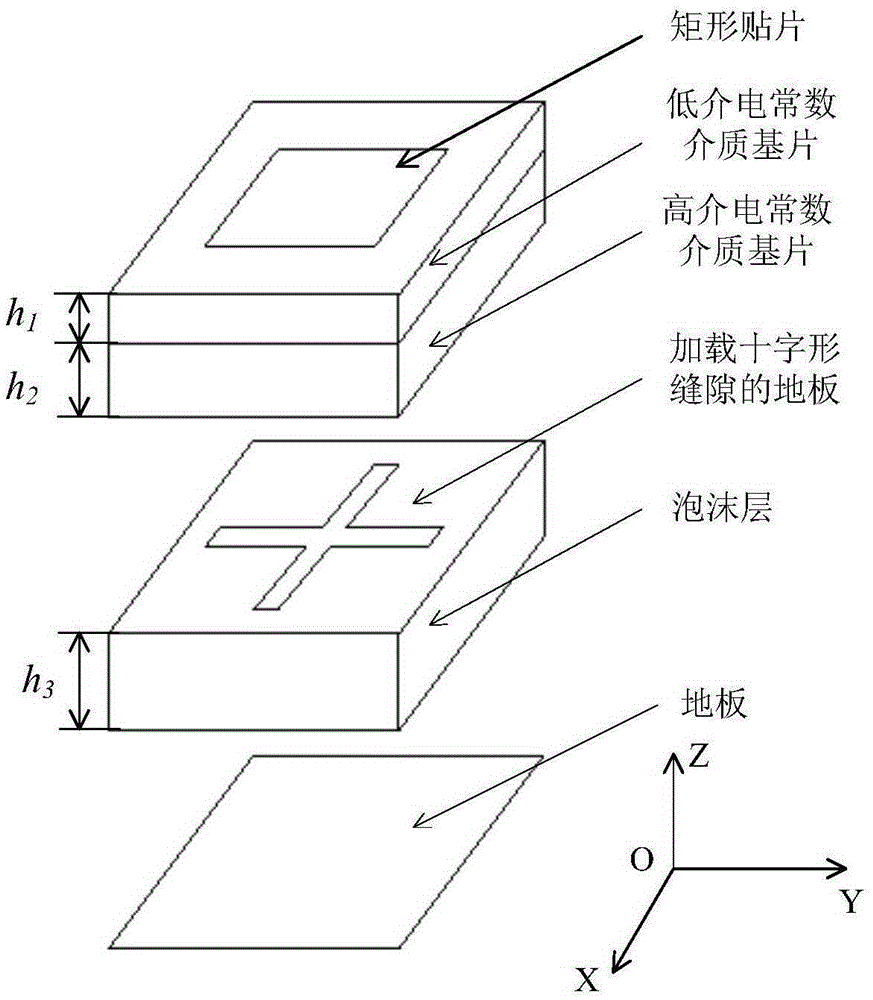

[0031] In this embodiment, what the low dielectric constant dielectric substrate adopts is the plate material of Rogers (Rogers) 5880, and its dielectric constant is 2.2; What the high dielectric constant dielectric substrate adopts is silicon nitrate (siliconnitrate) material, and its dielectric constant is 2.2. The electrical constant is 7; the length and width of the rectangular patch are equal, and the gap width in both directions is the same; the length and width of the entire unit plane are 13mm.

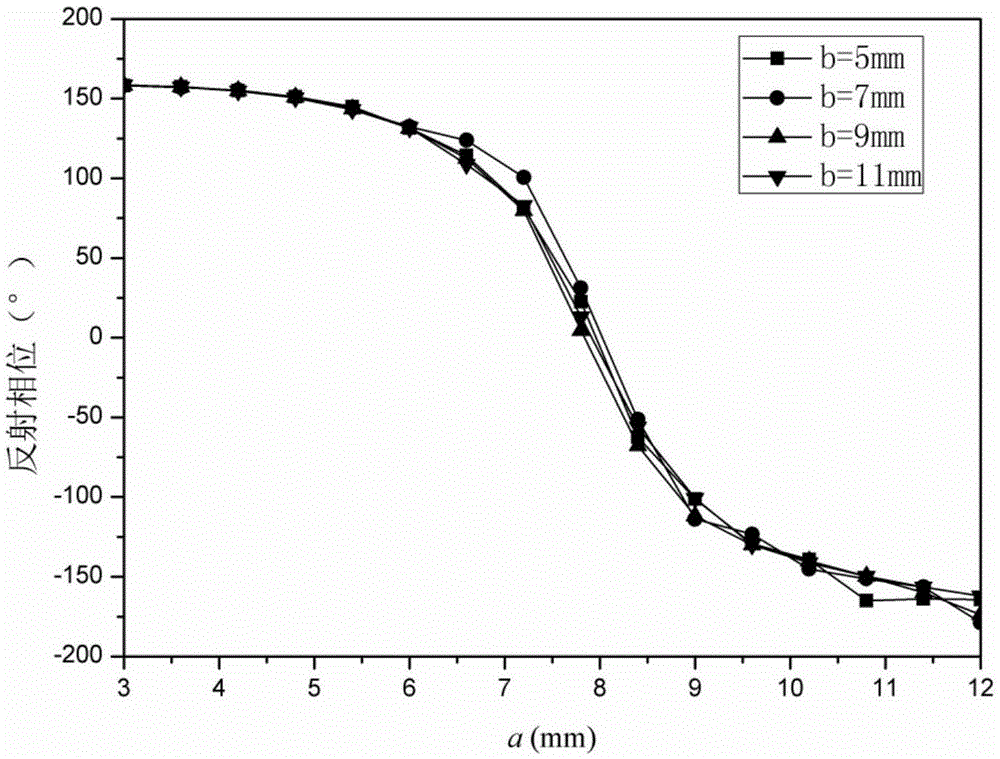

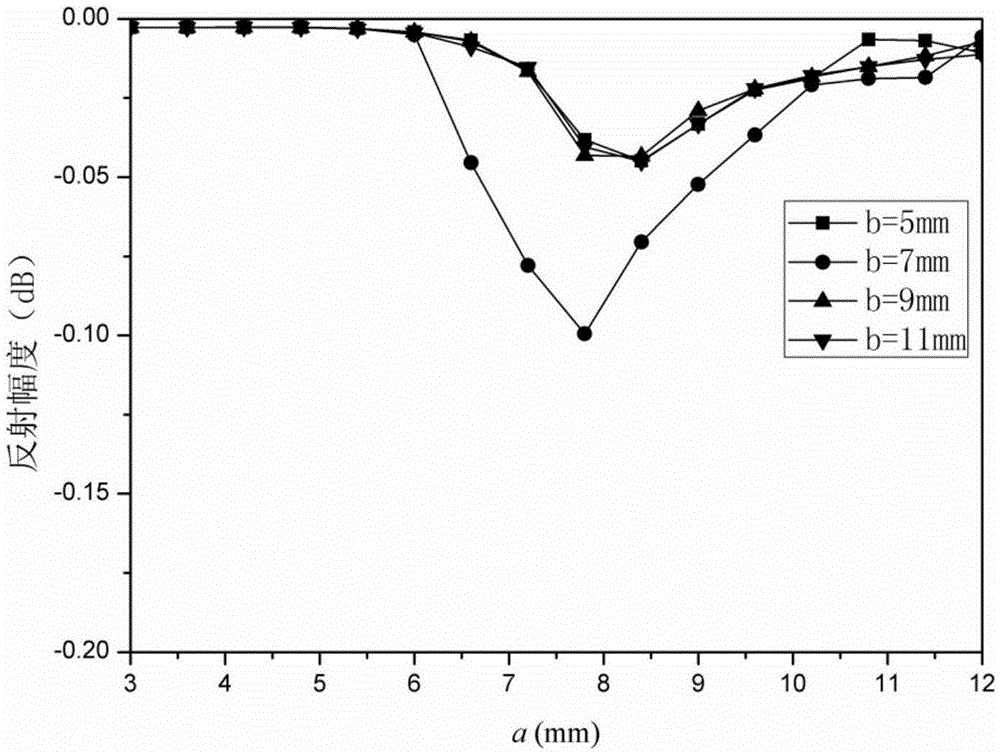

[0032] Such as figure 2 As shown, the unit is modeled and simulated using the high-frequency electromagnetic simulation software HFSS, and the curve of the reflection phase changing with the length of the gap is obtained. When the slot length in the y direction is different, the variation curves of the unit reflection phase with the slot length in the x direction are small, indicating that the ground-loaded cross-shaped slot dual-polarized microstrip reflectarray unit is inde...

Embodiment 2

[0040] In this embodiment, the feeding form of the antenna is positive feed, the focal diameter ratio F / D=0.8, and the distance from the phase of the feed source to the center of the array is 93.6 mm.

[0041] The antenna can reflect the linearly polarized feed source incident wave into a circularly polarized reflected wave. When the polarization direction of the linearly polarized feed source is the direction of the angle bisector of the angle formed by the x axis and the y axis, the incident The waves on the reflective array can be decomposed into linearly polarized waves in the x-direction and y-direction. Independently adjust the length of the unit gap in the x direction and y direction of each unit, so that the reflection phase in the x direction is ahead (or behind) the reflection phase in the y direction by 90°, so that the linearly polarized feed incident wave is reflected by the reflection array Afterwards, a right-handed (or left-handed) reflected wave is obtained. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com