Agricultural film

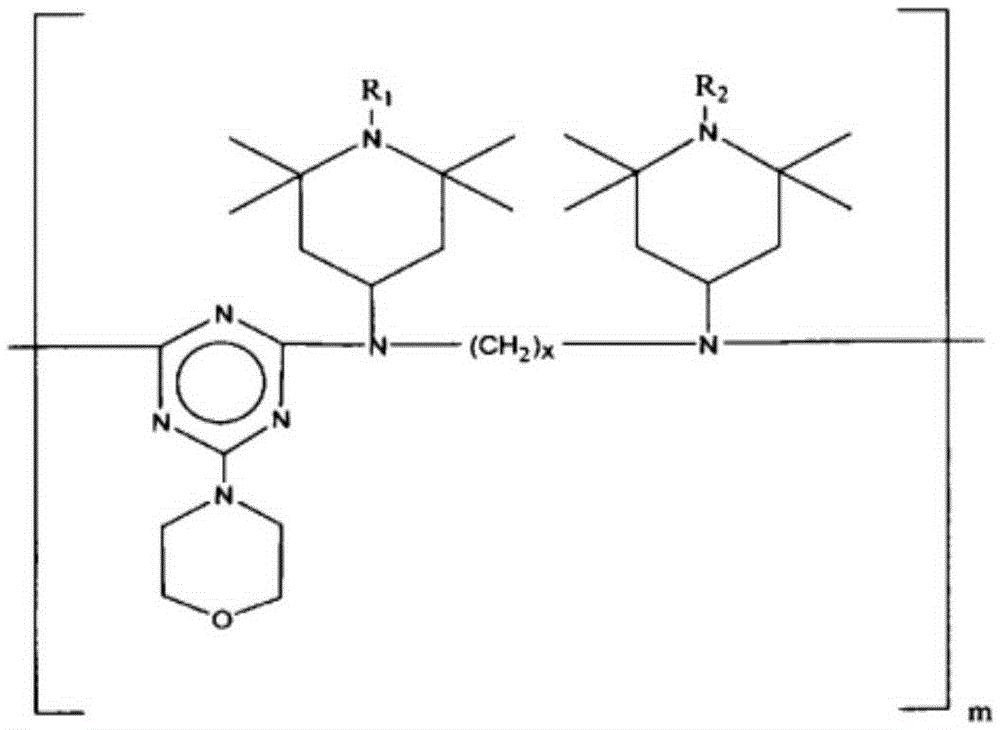

A technology of agricultural film and light stabilizer, which is applied in agriculture, agricultural machinery, agricultural machinery and machinery, etc., can solve the problems of agricultural film that have not yet been developed, and achieve the effect of long-term life cycle and prevention of chalking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0082] The content of the present invention will be described in detail by the following examples, but the scope of the present invention should not be limited to the examples.

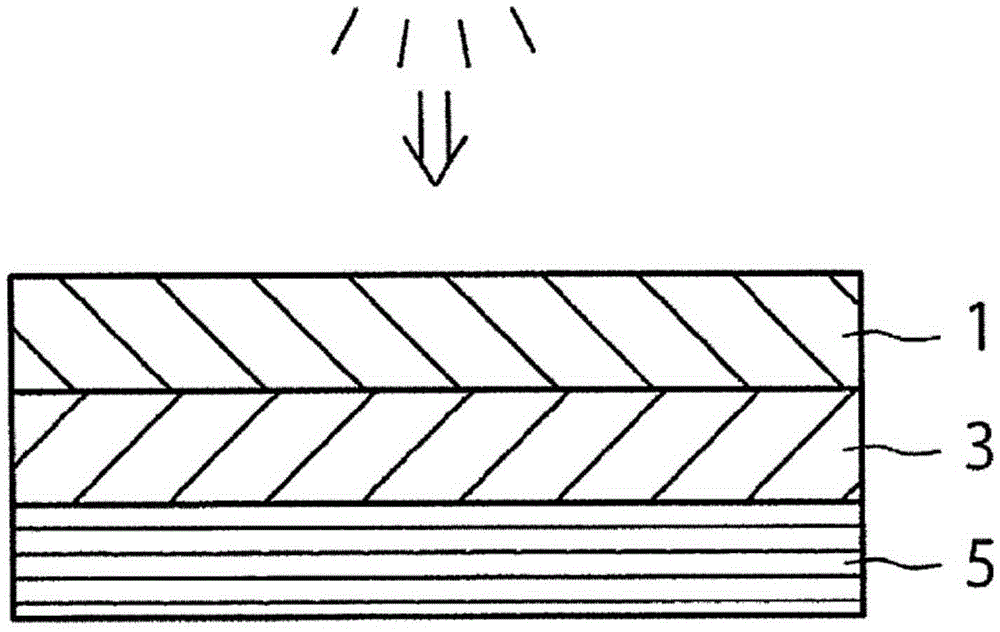

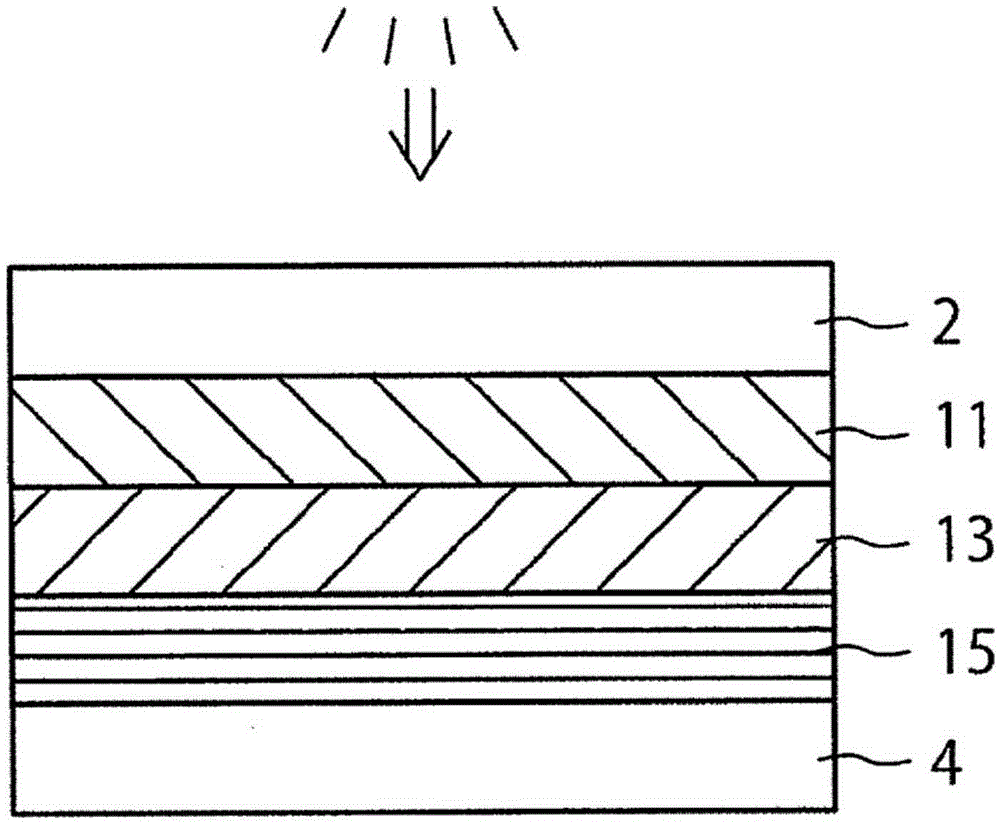

[0083] [Preparation of agricultural film (five-layer structure)]

[0084] Agricultural films with a five-layer structure of the outermost layer, the middle layer, and the innermost layer were prepared respectively. The preparation method is as follows: using methods such as co-extrusion T-die method, co-extrusion air-cooled inflation method, co-extrusion water-cooled inflation method, etc., respectively make the outermost layer (transparent layer), the first middle layer (white Pigment layer), the second intermediate layer (black pigment layer), the third intermediate layer (white pigment layer), and the innermost layer (transparent layer) five-layer agricultural film. The film thickness of the prepared agricultural film is about 150 μm.

[0085] The compositions and the like of each layer (A layer ...

Embodiment 5

[0087] Example 5 An agricultural film having a four-layer structure of the outermost layer and the middle layer (1 to 3) was prepared. Example 6 An agricultural film having a four-layer structure of an intermediate layer (1 to 3) and an innermost layer was prepared. The preparation method is as follows: using methods such as co-extrusion T-die method, co-extrusion air-cooled inflation method, co-extrusion water-cooled inflation method, etc., respectively make the outermost layer (transparent layer) or the innermost layer (transparent layer) , a four-layer agricultural film of the first intermediate layer (white pigment layer), the second intermediate layer (black pigment layer), and the third intermediate layer and the innermost layer (white pigment layer). The film thickness of the prepared agricultural film is about 150 μm.

[0088] [Preparation of agricultural film 3 (three-layer structure)]

[0089] Agricultural films having a three-layer structure of the outermost layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shading coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com