On-chip microfluidic processing of particles

A particle and fluid communication technology, applied in laboratory containers, gas/liquid distribution and storage, instruments, etc., can solve problems such as height variability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 8

[0454] Example 8 describes the use of an on-chip cleaning system.

[0455] In some cases, the size-based separation methods described herein do not use centrifugation and / or sedimentation. In some cases, the size-based separation methods described herein use centrifugation or sedimentation.

[0456] (w) cone angle

[0457] The obstacles or posts may be cylindrical. In some cases, obstacles on the device are not perfectly cylindrical. The obstacles or at least 50% of the obstacles in the array may have Taper angles of 1.5°, 1°, 0.5°, 0.4°, 0.3°, 0.2° or 0.1°. Obstacles may have a cone angle of 0°. The obstacles, or at least 50% of the obstacles in the array, may have a range of about 0.1° to about 1°, about 1° to about 2°, about 2° to about 3°, about 3° to about 4°, or about 1° to about 4° cone angle.

[0458] H. Materials of Construction and Surface Chemistry

[0459] In some embodiments, the device is fabricated by heat molding PMMA and / or polycarbonate. Thermoplasti...

Embodiment 1

[0649] Example 1: Manufacture

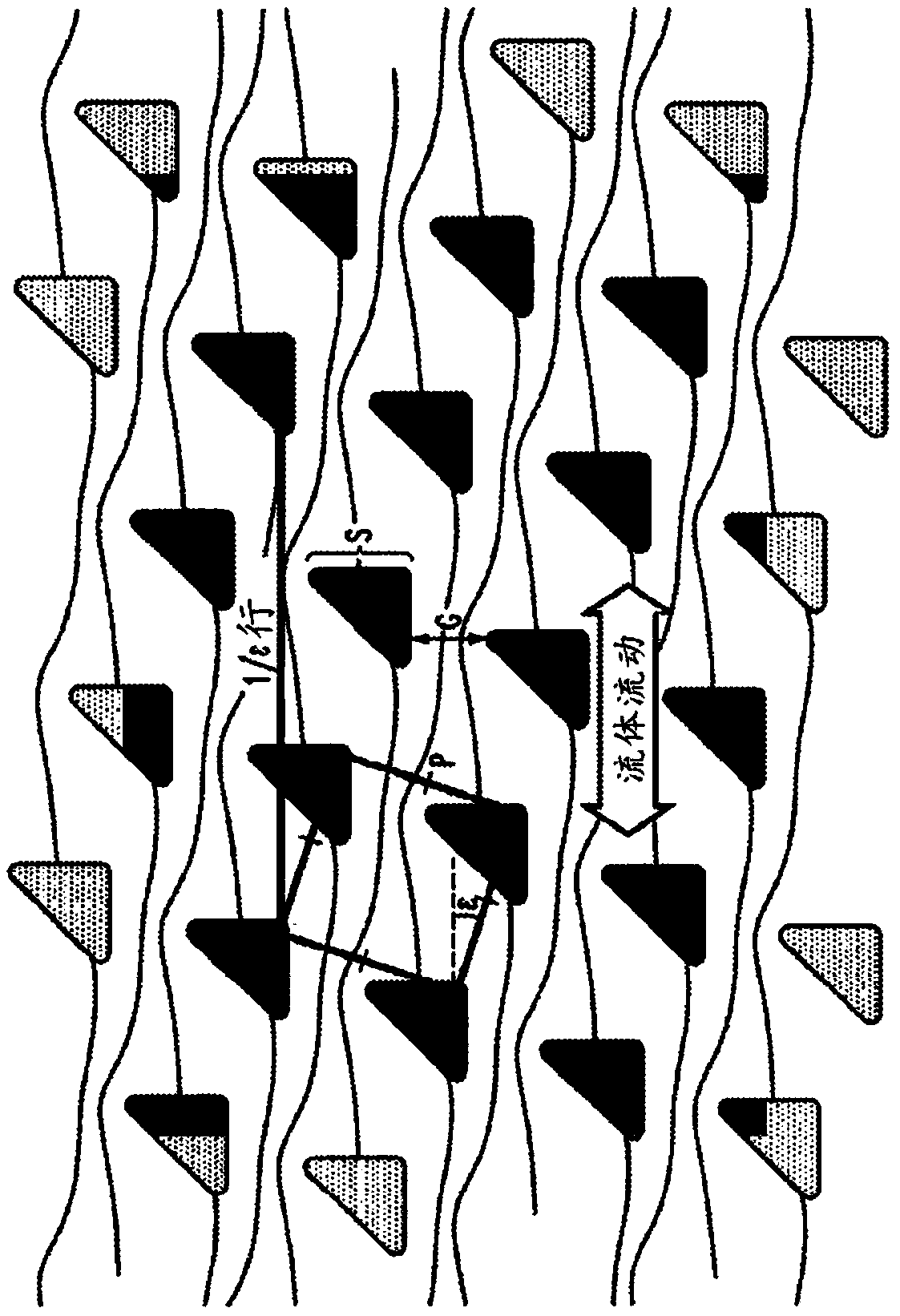

[0650] Chips are fabricated using highly anisotropic deep reactive ion etching (DRIE) in crystalline silicon polished substrates using a "Bosch" process that cycles between etch and sidewall passivation steps, so the pillar side The walls are only ~1° from vertical. Optical lithography defines the pattern. Through-substrate vias are micromachined to support fluid loading / unloading from the backside, which mate with plastic fixtures with connectors for input source and output collection. Chips were pretreated with triblock copolymer F108 (2 g / l) to reduce cell adhesion. Tuning chip design parameters (eg, critical size for bouncing behavior) for high yield.

Embodiment 2

[0651] Example 2: Operation

[0652] Cell surface antigens targeting multiple leukocyte differentiation (i.e., CD45 / CD14 / 15 (to determine single granulocyte type count), CD3 / 4 / 8 (to count common T lymphocyte subsets), CD19 / 56 / 14 (to identify B lymphocytes and NK cells), CD45 / CD235a / CD71 (to identify any contaminating erythroid cells)) and incubation with viability dyes ("immunostaining") Leukocytes from 0.1ml-1ml red blood cell lysed whole blood (optionally diluted with buffer (calcium and magnesium free PBS containing 1% BSA and 4mM EDTA) and optionally spiked with leukemic cells) . This is done routinely (ie, off-chip). Cells are then washed and concentrated to ~1-10 million cells / mL using a DLD chip designed to move leukocytes and leukemia cells from an initial stream of input cell suspension containing fluorescent monoclonal antibodies to Outflow of fresh buffer against the chip wall ( Figure 17B ).

[0653] The method can recover >90% of the input leukocytes and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com