Laser implantation preparation method for multi-dimensional continuous fine structure

A microstructure and laser technology, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of continuous surface microstructure preparation difficulties, to avoid melting and vaporization, enhance bonding strength, easy to add and The effect of discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

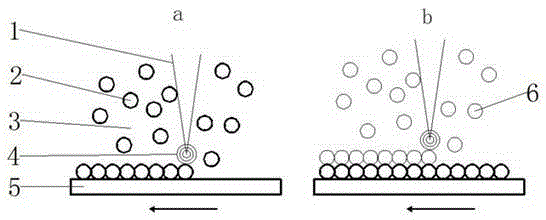

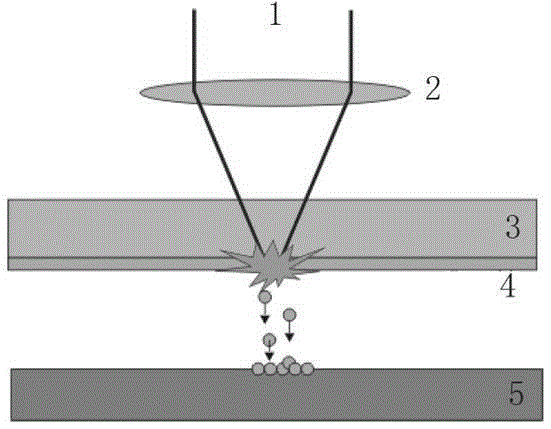

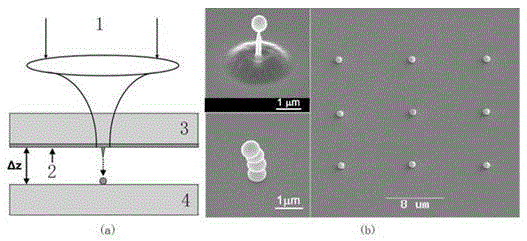

[0024] A preparation method for laser implantation of multi-dimensional continuous microstructures, laser light (1) is focused on a suspension (3) containing fine particles (2) through a convex lens, and the energy of the laser exceeds the breakdown threshold of the suspension (3), Optical breakdown occurs at the focal point to generate cavitation bubbles (4), laser-induced shock waves and high-speed micro-jet impact the fine particles (2) in the suspension (3) into the substrate (5); The 3D printing scanning feeding of the three-dimensional fine platform, combined with the repeated irradiation of the laser, and the continuous replenishment of the suspension containing fine particles, use the laser-induced shock wave and high-speed micro-jet to prepare the same material on the substrate. of microstructure.

Embodiment 2

[0026] A method for preparing a multidimensional continuous microstructure by laser implantation, in which different types of particles (6) are injected into a suspension, and multi-level microstructures of different materials can be prepared by using laser-induced shock waves and high-speed microjets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com