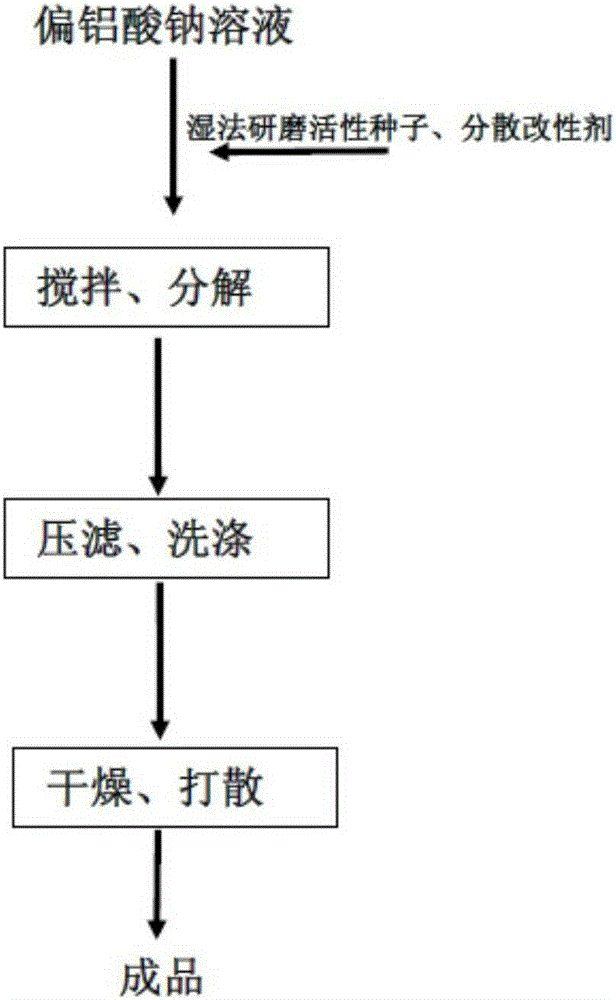

Preparation method of high-dispersion superfine aluminium hydroxide

A technology of ultra-fine aluminum hydroxide and aluminum hydroxide, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc. The application performance of products is deteriorated, and the effect of high dispersion performance, improved processing performance and reduction of agglomerates can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

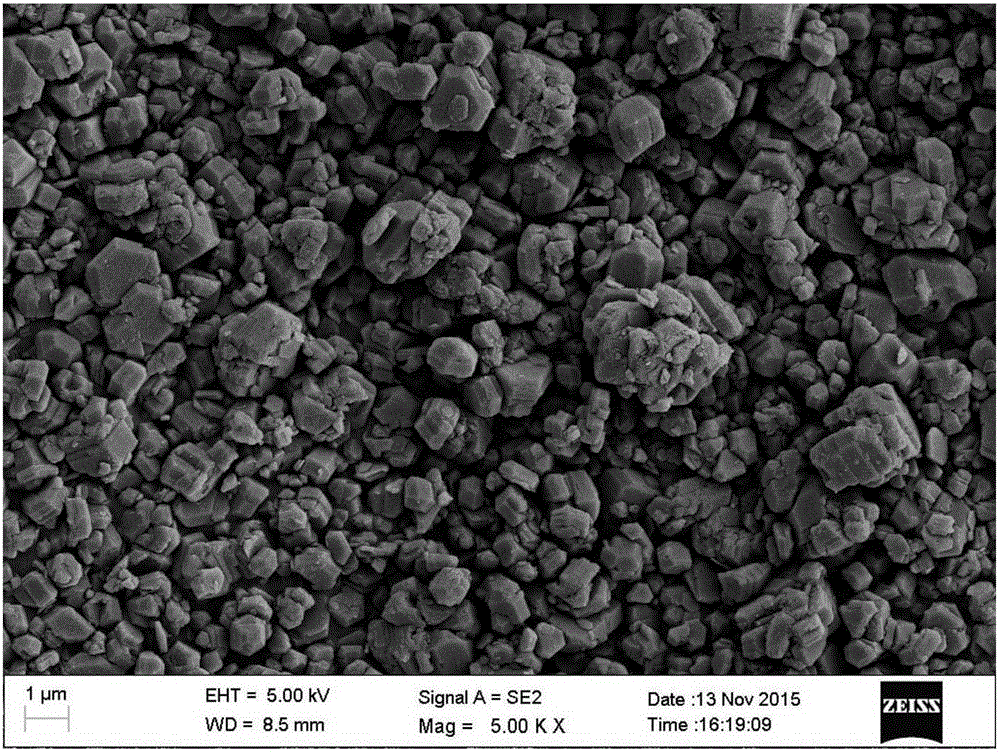

[0015] A method for preparing highly dispersed ultrafine aluminum hydroxide, using 100 parts of sodium metaaluminate solution with an alumina content of 235g / L and a solution caustic ratio of αK=1.52 as raw material, at a reaction temperature of 65°C, adding 1.5 Add 1.2 parts of sodium citrate to 1 part of wet-ground seed crystals, stir and react for 8 hours, then carry out solid-liquid separation, washing, drying and impact milling for the resulting slurry. The frequency of the impact mill host is 40HZ, and the frequency of the classifier 35HZ, and finally get ultra-fine powder aluminum hydroxide for packaging, product particle size D 100 7um, the SEM photo of the product is attached figure 2 .

Embodiment 2

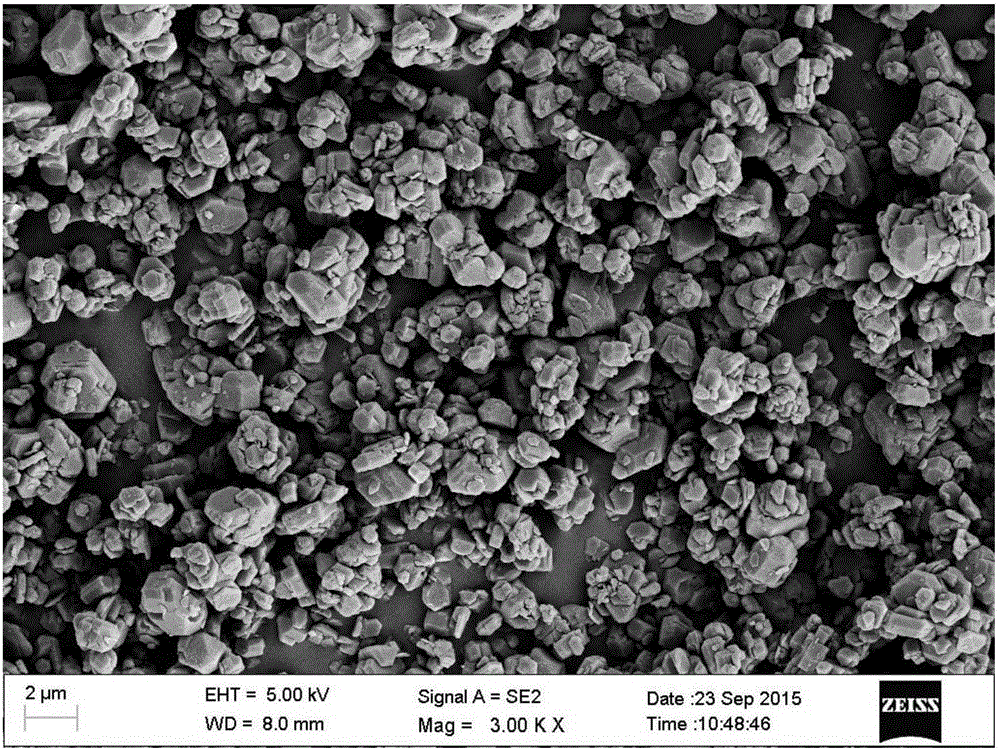

[0017] A method for preparing highly dispersed ultrafine aluminum hydroxide, using 100 parts of sodium metaaluminate solution with an alumina content of 220g / L and a solution caustic ratio of αK=1.60 as a raw material, adding 2 Add 2 parts of oleic acid amide to 1 part of wet-ground seed crystals, stir and react for 10 hours, then carry out solid-liquid separation, washing, drying and impact milling to disperse the obtained slurry. The frequency of the impact mill host is 30HZ, and the frequency 25HZ, and finally get superfine powder aluminum hydroxide for packaging, product particle size D 100 It is 8.5um, the SEM photo of the product is attached image 3 .

Embodiment 3

[0019] A method for preparing highly dispersed ultrafine aluminum hydroxide, using 100 parts of sodium metaaluminate solution with an alumina content of 260 g / L and a solution caustic ratio of αK = 1.42 as raw material, at a reaction temperature of 55°C, adding 0.75 Add 1.2 parts of silane A151 to 1 part of wet-grinding seed crystals, stir and react for 11 hours, then carry out solid-liquid separation, washing, drying and impact milling to disperse the obtained slurry. 45HZ, finally get ultra-fine powder aluminum hydroxide for packaging, product particle size D 100 6.5um, the product SEM photo is attached Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com