Material pretreatment device for aerobic composting and biological drying of solid waste and material pretreatment method

A technology of solid waste and pretreatment device, applied in biological organic part treatment, fertilization device, organic fertilizer and other directions, can solve the problems of adding conditioner, uneven mixing of materials, etc., to reduce the volatilization of ammonia gas, reduce ammonia gas Release and enhance the effect of biological nitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

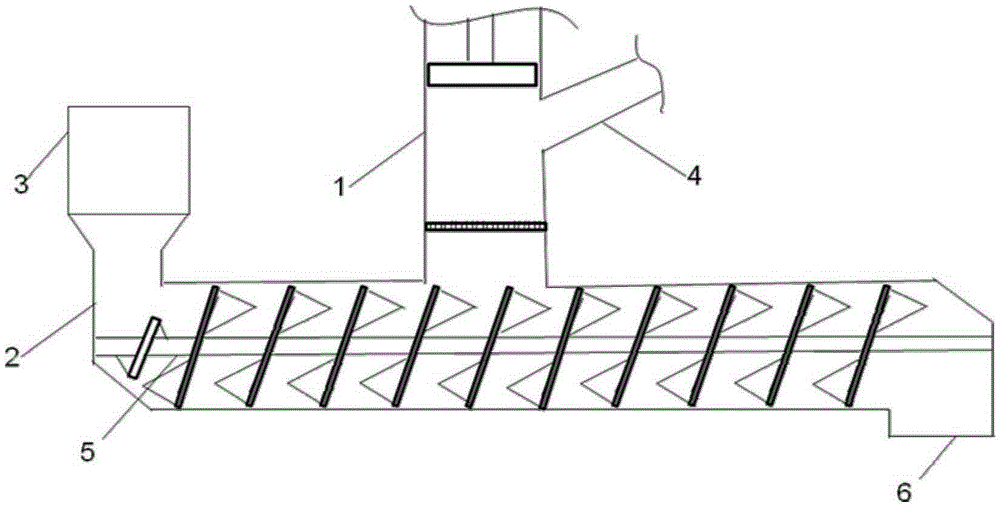

[0017] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the material pretreatment device for aerobic composting and biological drying of solid waste in this embodiment includes a press machine 1 and a mixer 2. Connected with the mixer 2, the top of the press 1 is provided with a feed inlet 4 of the press, the left end of the top of the mixer 2 is provided with a first inlet 3, and the inside of the mixer 2 is provided with a spiral stirring knife 5, The bottom of the mixer 2 is provided with a discharge port 6 .

specific Embodiment approach 2

[0018] Specific implementation mode two: the material pretreatment method of solid waste aerobic composting and biological drying in this implementation mode is carried out according to the following steps:

[0019] 1. Put the organic solid waste with a moisture content of ≤70% after drying, mechanical pressure filtration, biological drying, aerobic composting or without any treatment into the mixer 2 through the first feeding port 3 for crushing. When the average particle diameter is below 3cm, it is material 2;

[0020] Two, then put the organic solid waste with a moisture content ≥ 50% into the press machine 1 through the feed port 4 of the press machine, and press it into strips with a diameter of 0.1 to 2 cm or granules with a particle size of 0.1 to 2 cm. for material one;

[0021] 3. Material 1 is added to material 2 of mixer 2 at a uniform speed by feeder 1, and the mixed material of material 1 and material 2 is stirred and mixed by mixer 2 during the addition process...

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 2 in that: in step 1, the particles are crushed until the average diameter of the particles is 2 cm. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com