Purification device and method for organic solvent

An organic solvent, purification device technology, applied in the direction of organic chemistry, organic electrolyte, carbonate/haloformate purification/separation, etc. The effect of increasing the evaporation area of water and reducing the probability of excessive impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

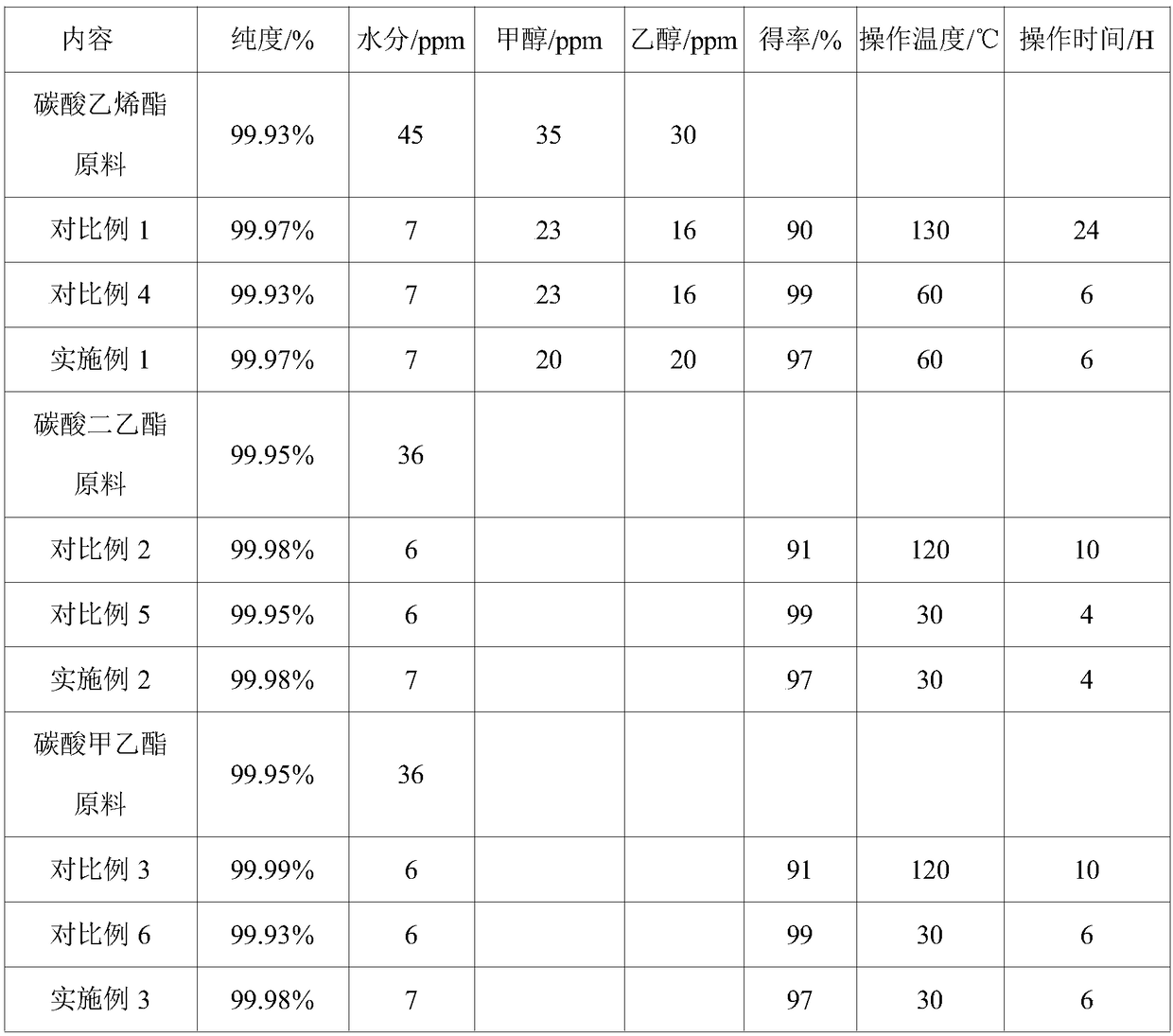

Embodiment 1

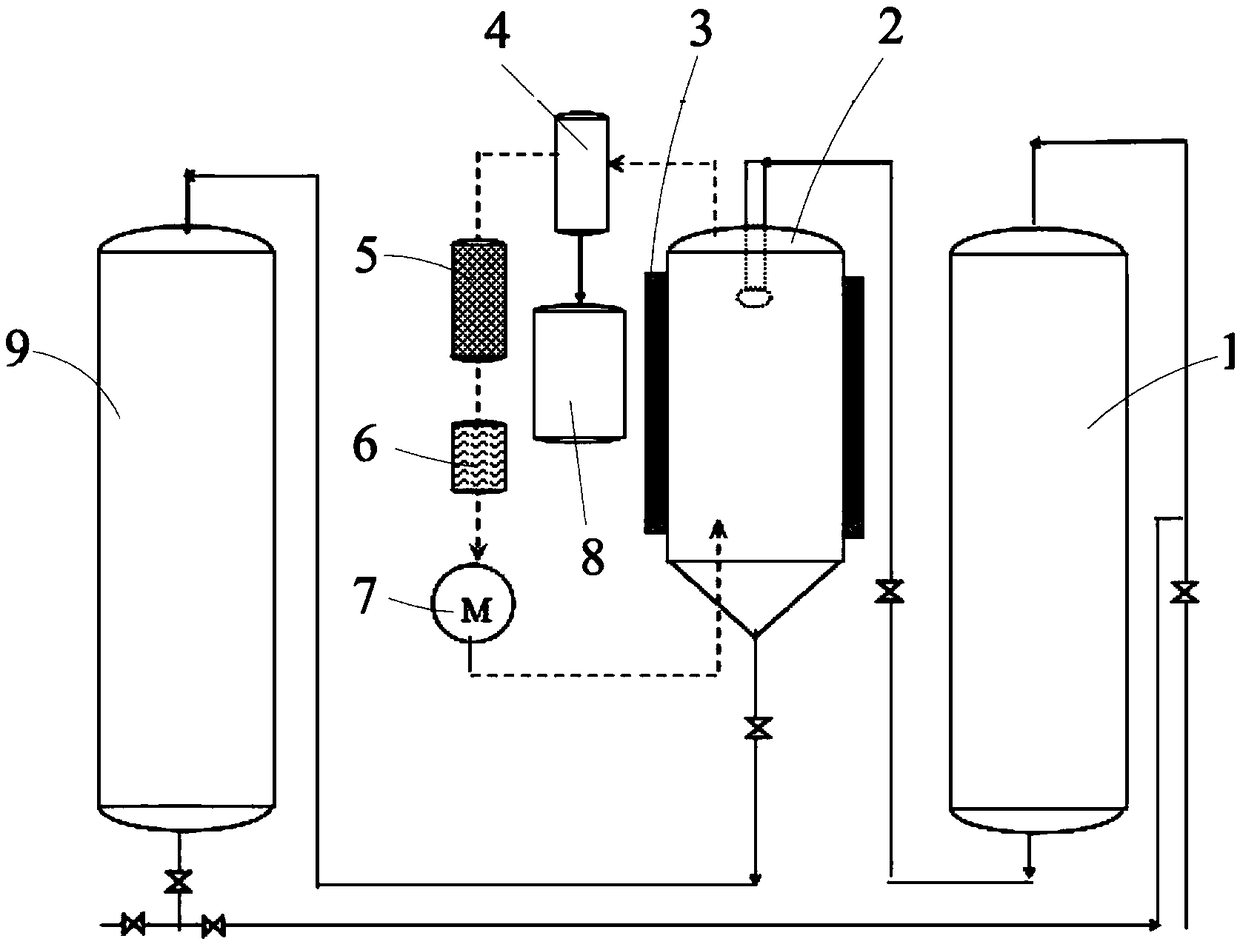

[0051] Such as figure 1 As shown, an organic solvent purification device includes a raw material storage tank 1, an atomization dryer 2, a heater 3, a gas-liquid separator 4, a molecular sieve absorber 5, a filter 6, a gas circulation pump 7, and a first collection tank 8 Connect with the second collection tank 9, the atomization dryer 2 is connected with the raw material storage tank 1, the heater 3 is arranged on the atomization dryer 2, the atomization dryer 2, the gas-liquid separator 4, the molecular sieve absorber 5, and the filter 6 It is connected with the gas circulation pump 7 in turn to form a circulation loop, the first collector 8 is connected with the gas-liquid separator 4, the second collection tank 9 is connected with the bottom of the atomization dryer 2, and the second collection tank 9 is also connected with the raw material storage tank 1 connect. The circulation gas of the gas circulation pump 7 is an inert gas.

[0052] The present embodiment adopts ab...

Embodiment 2

[0058] The difference from Example 1 is that in this example, an organic solvent purification device is used to purify diethyl carbonate, no heating is required during the operation, and the temperature is normal temperature.

[0059] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0061] The difference from Example 1 is that in this example, an organic solvent purification device is used to purify ethyl methyl carbonate, no heating is required during the operation, and the temperature is normal temperature.

[0062] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com