Synthetic method of 1,3-dithiane structure-containing polysubstituted olefin derivatives

A dithiane, multi-substitution technology, applied in the field of synthesis of multi-substituted olefin derivatives

- Summary

- Abstract

- Description

- Claims

- Application Information

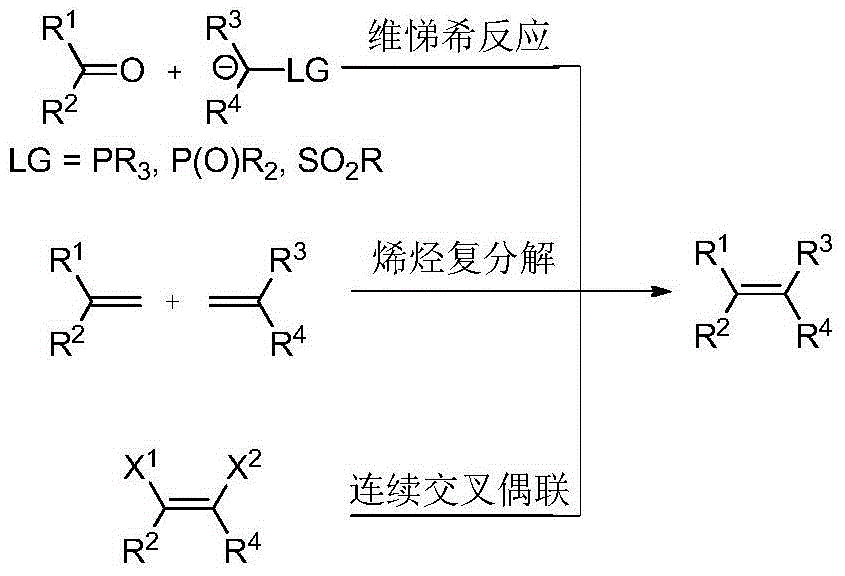

AI Technical Summary

Problems solved by technology

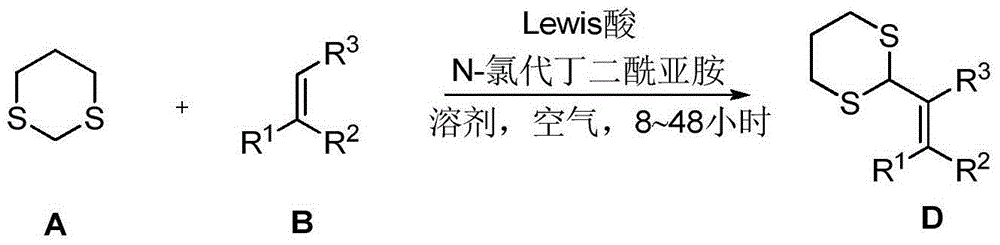

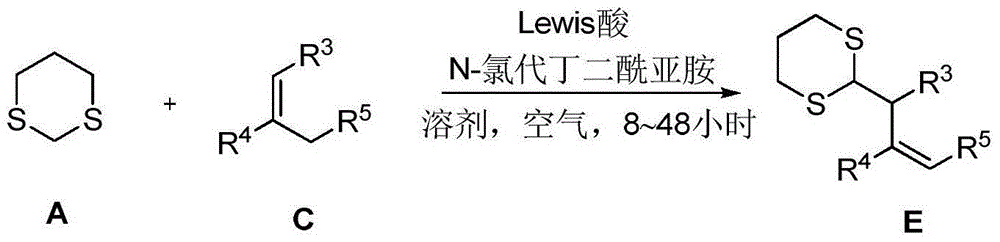

Method used

Image

Examples

Embodiment 1

[0021] Example 1 In a 50 milliliter round bottom flask, add 1,3-dithiane (1mmol), add N-chlorosuccinimide (1.2mmol) after dissolving with 10 milliliters of 1,2-dichloroethane , reacted for 40 to 60 minutes, then added 1,1-stilbene (0.9 mmol) and boron trifluoride ether (or anhydrous ferric chloride, methanesulfonic acid) (0.1 mmol), and reacted at room temperature for 10 to 12 Hour. After TLC monitoring, the reaction was stopped after the reaction was complete, and the product was obtained by column chromatography after evaporating the solvent.

Embodiment 2

[0022] Example 2 In a 50 milliliter round bottom flask, add 1,3-dithiane (1mmol), add N-chlorosuccinimide (1.2mmol) after dissolving with 10 milliliters of 1,2-dichloroethane , reacted for 40 to 60 minutes, then added 1,1-bis(4-methylphenyl)-propene (0.9mmol) and boron trifluoride-free ether (or anhydrous ferric chloride, methanesulfonic acid) (0.1 mmol), react at room temperature for 10-12 hours. After TLC monitoring, the reaction was stopped after the reaction was complete, and the product was obtained by column chromatography after evaporating the solvent.

Embodiment 3

[0023] Example 3 In a 50 milliliter round bottom flask, add 1,3-dithiane (1mmol), add N-chlorosuccinimide (1.2mmol) after dissolving with 10 milliliters of 1,2-dichloroethane , reacted for 40 to 60 minutes, then added 1-phenyl-1-(4-chlorophenyl)-ethylene (0.9mmol) and boron trifluoride ether (or anhydrous ferric chloride, methanesulfonic acid) (0.1 mmol), react at room temperature for 10-12 hours. After TLC monitoring, the reaction was stopped after the reaction was complete, and the product was obtained by column chromatography after evaporating the solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com