A kind of transfer coating composition with high temperature resistance and high aluminum layer adhesion and application thereof

A technology for transferring coatings and compositions, applied in the direction of coatings, etc., can solve the problems of surface fogging, resin material bubbles and pores, poor temperature resistance, etc., and achieve the effect of good temperature resistance and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

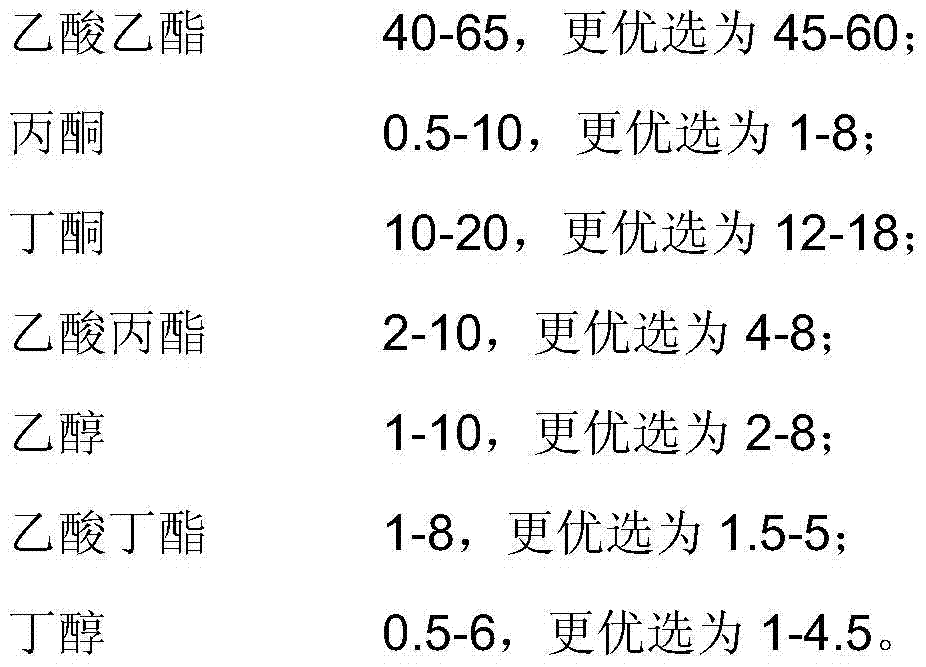

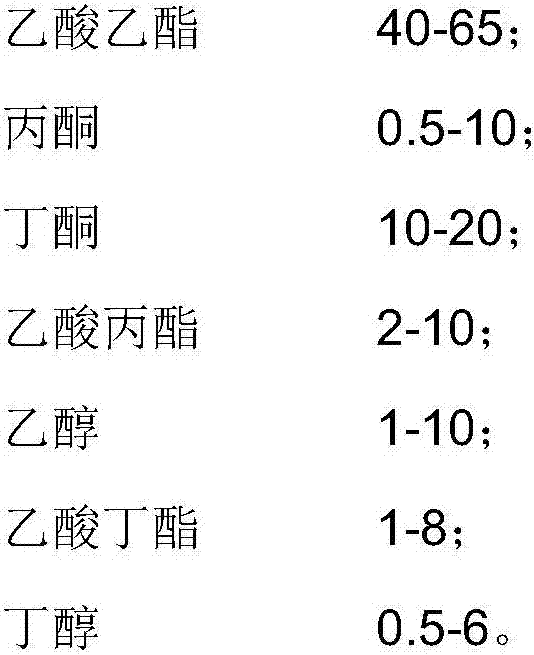

Method used

Image

Examples

Embodiment 1

[0049] Matrix resin 1) (Matrix1): methyl methacrylate homopolymer

[0050] Number average molecular weight 40000, ester 0.8mgKOH / g, softening point (ring and ball method) 200°C, Tg (DSC) 110°C, density (20°C) 1.18kg / L, viscosity (25°C, 25wt% butanone solution, Brookfield Viscometer) 30mPa·S

[0051] Matrix resin 2) (Matrix2): cellulose acetate-butyrate

[0052] Acetyl 29.5wt%, butyryl 17.5wt%, melting temperature 230-240°C, Tg151°C, viscosity 1.1-1.2 poise

[0053] Mix the components according to the ratio in Table 1.

Embodiment 2

[0055] Matrix resin 1): Methyl methacrylate homopolymer

[0056] Number average molecular weight 50000, ester 1mgKOH / g, softening point (ring and ball method) 220°C, Tg (DSC) 130°C, density (20°C) 1.15kg / L, viscosity (25°C, 25wt% methyl ethyl ketone solution, Brookfield viscosity meter) 25mPa·S

[0057] Matrix resin 2): cellulose acetate-butyrate

[0058] Acetyl 28.1wt%, butyryl 18.6wt%, melting temperature 250°C, Tg160°C, viscosity 1.15-1.22 poise

[0059] Mix the components according to the ratio in Table 1.

Embodiment 3

[0061] Matrix resin 1): Methyl methacrylate homopolymer

[0062] Number average molecular weight 40000, ester 0.8mgKOH / g, softening point (ring and ball method) 200°C, Tg (DSC) 110°C, density (20°C) 1.18kg / L, viscosity (25°C, 25wt% butanone solution, Brookfield Viscometer) 30mPa·S

[0063] Matrix resin 2): cellulose acetate

[0064] Acetyl 30.7wt%, melting temperature 225°C, Tg143°C, viscosity 1.12-1.2 poise

[0065] Mix the components according to the ratio in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com