Bottom milling device for electrolytic copper anode plate shaping unit

An anode plate, electrolytic copper technology, applied in the direction of electrolysis components, electrolysis process, process efficiency improvement, etc., can solve the problems of too many movements completed by the trolley, large vibration of the anode plate, unreliability of the device, etc., so as to improve the milling quality , The effect of reducing weight and reducing points of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

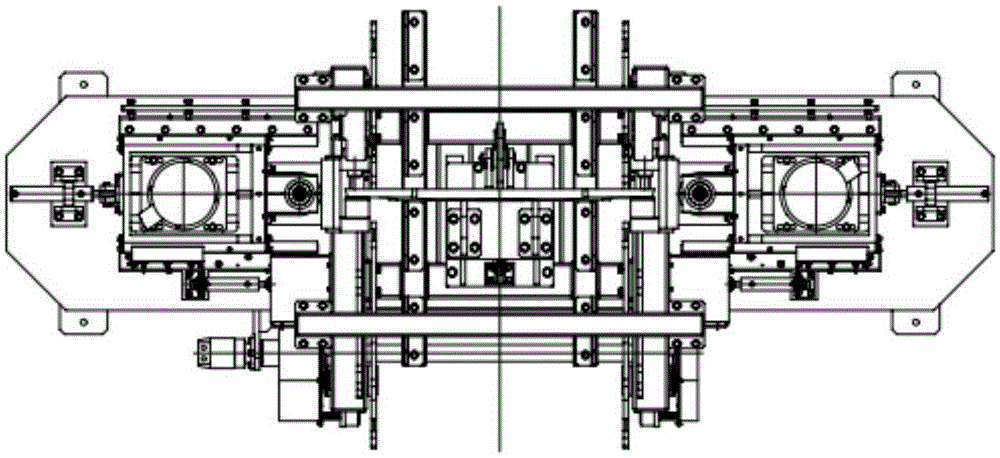

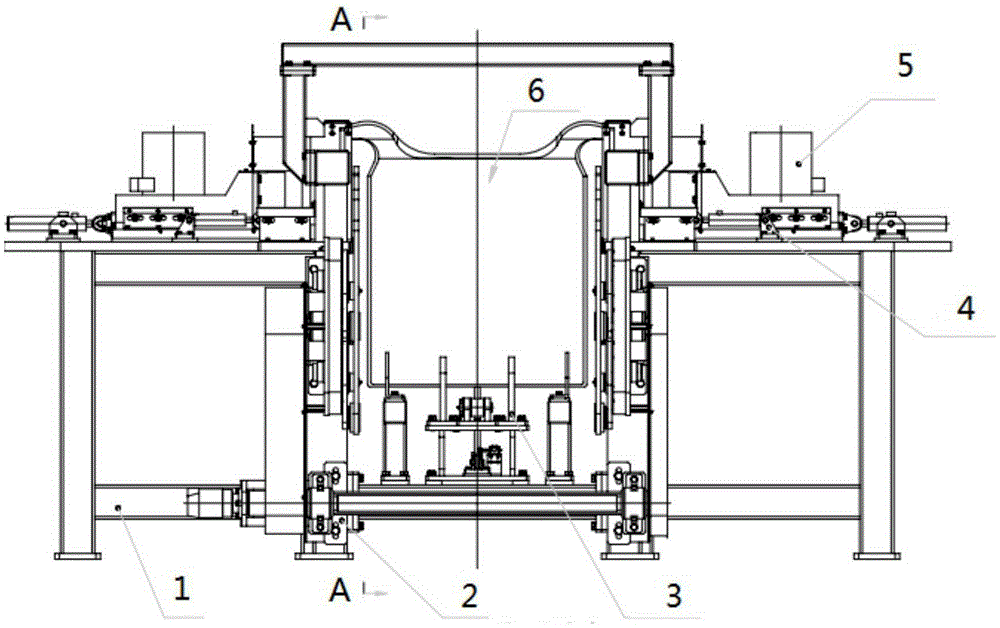

[0027] In the figure, 1-frame and upper clamping mechanism, 2-step plate feeding mechanism, 21-hydraulic motor, 22-base, 23-transmission shaft, 24-bearing and bearing seat, 25-left shield, 26 -Right guard, 27-standard liquid chain transmission system, 28-reduction box and cam plate, 29-swing arm, 210-small swing lever, 211-anode plate card slot, 212-connecting surface with the frame, 3- Lower clamping mechanism, 4-centering mechanism, 41-push plate, 42-guide shaft, 43-connecting plate, 44-oil cylinder and fixing seat, 5-milling mechanism, 6-anode plate.

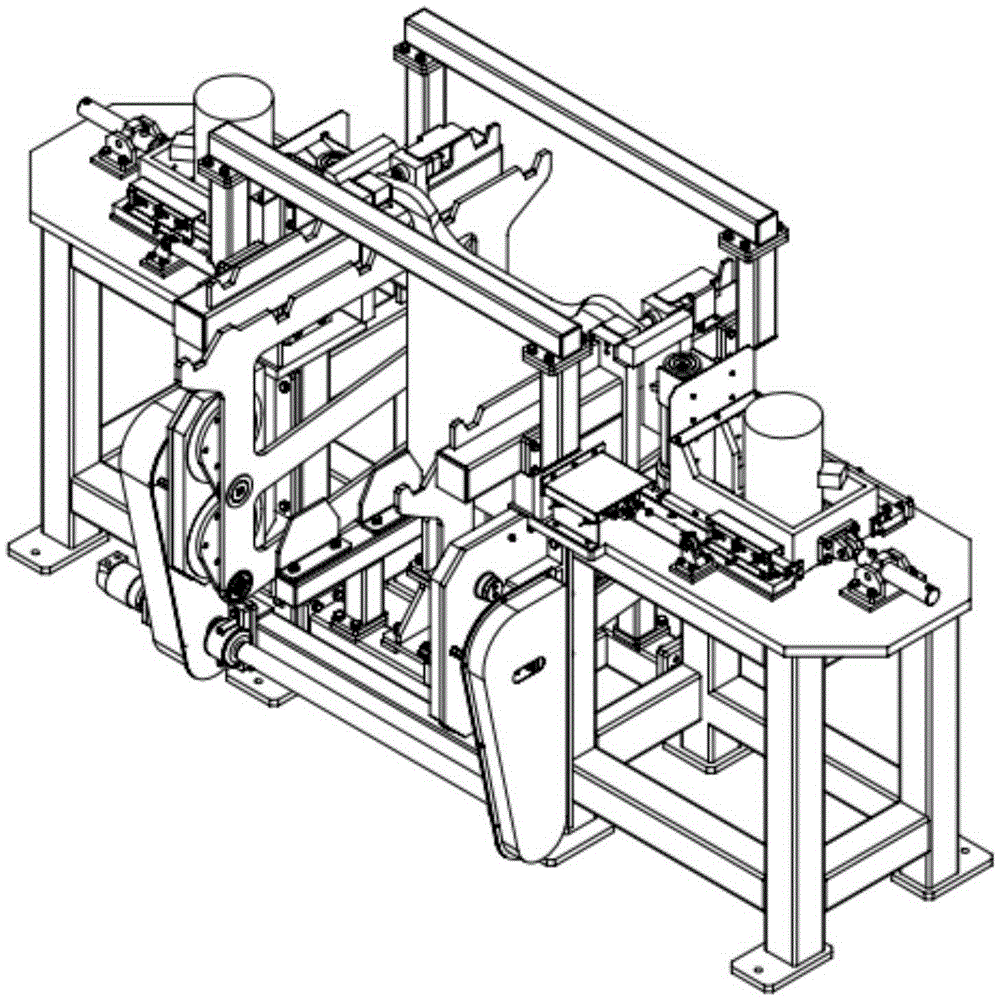

[0028] Such as Figure 1-4 As shown, a bottom milling device of an electrolytic copper anode plate shaping unit includes a frame and an upper clamping mechanism 1, a plate feeding mechanism, a centering mechanism 3, a lower clamping mechanism 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com