Pressure vessel convenient processing method and device for multi-state hybrid material

A technology for pressure vessels and materials, which is applied to pressure vessels, valve operation/release devices, valve devices, etc., can solve problems such as incompatibility with production practices, easy damage and maintenance, narrow application range, etc., and achieve long-term sealing Reliable, time-saving, energy-saving and cost-effective, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

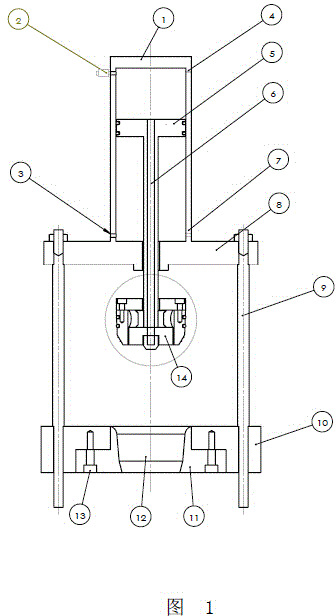

[0037] Example 1, the present invention can be used in process type intermittent steam explosion tank.

[0038] The first start-up must be preheated, then close the discharge valve, open the feed valve, close the feed valve after manual feeding, feed steam to 2.5mpa to stop steam, open the discharge valve after 10 seconds of heat preservation, the material is sprayed instantly, and then Close the discharge valve and open the feeding valve to feed, so that the cycle is completed to complete the intermittent continuous operation.

[0039] In this case the tank capacity is 0.04m 3 , The diameter of the feed valve is 75mm, the diameter of the discharge valve is 50mm, there are 4 seals, 3 pillars, and the control program is programmed according to the prior design.

example 2

[0040] Example 2, the present invention can be used in the batch type steam explosion pot of production model.

[0041] The specific operation is the same as that of the process model, except that manual feeding is changed to machine feeding, the steam pressure is 2mpa, the holding time is 30s, and the blasting materials return to the receiving bin.

[0042] In this case the tank capacity is 3m 3 , The diameter of the feed valve is 175mm, the diameter of the discharge valve is 100mm, there are 5 seals, and 4 pillars. The control program is compiled according to the process requirements and on-site production practice.

example 3

[0043] Example 3, the present invention can be used in a cooking separation tank.

[0044] The specific operation is the same as that of the steam explosion tank, except that the steam is changed to 120 degrees, the holding time is 15 minutes, and the material out of the tank directly enters the next process for further processing.

[0045] In this case the tank capacity is 5m 3 , The diameter of the feed valve is 200mm, the diameter of the discharge valve is 125mm, there are 4 seals, and 3 pillars. The control program is compiled according to the process requirements and on-site production practice.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com