High-conversion-efficiency potential-induced degradation (PID)-resisting crystalline silicon solar cell and manufacturing method thereof

A solar cell, conversion efficiency technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of high production cost of anti-PID crystalline silicon solar cells, low cell conversion efficiency, etc., to reduce migration, High cell conversion efficiency and reduced ion accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The structure of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the parts in the present invention that are the same as those of the prior art will be referred to the prior art.

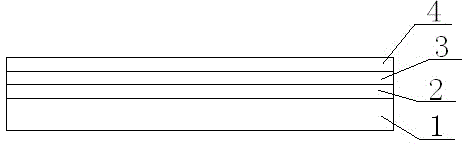

[0019] like figure 1 As shown, the high conversion efficiency anti-PID crystalline silicon solar cell of the present invention includes a silicon wafer 1, a high refractive index silicon nitride passivation layer 2 deposited on the front side of the silicon wafer, with a refractive index of 2.2~2.3 and a film thickness of 1~2. 10nm; the graphene conductive layer 3 coated on the high refractive index silicon nitride passivation layer 2, with a thickness of 1~10nm; the refractive index silicon nitride anti-reflection layer 4 deposited on the graphene conductive layer 3, the refractive index It is 2.0~2.1, and the film thickness is 60~80nm.

[0020] The manufacturing method of high conversion efficiency ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com