Preparation method of large-area perovskite micro-nano wire array and application thereof

A perovskite, micro-nano technology, applied in nanotechnology, semiconductor/solid-state device manufacturing, photovoltaic power generation, etc., can solve problems such as difficulty in forming organic lead halide perovskite nanowire array array devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dissolve 16mg of CH3NH3I in 1ml of DMF, and stir for 2min with a magnet; put 46mg of PbI2 into the prepared DMF solution of CH3NH3I, and stir at a constant temperature on a hot stage at 40°C for 2h to obtain a perovskite CH3NH3PbI3 precursor solution.

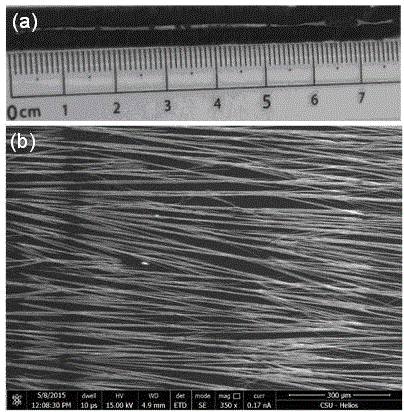

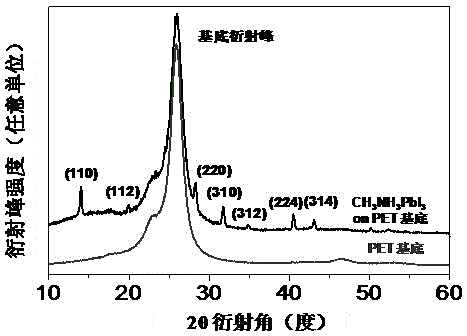

[0025] Take a PET substrate of A4 size (210mm×297mm) or a SiO2 substrate of 50mm×100mm, wipe it with a dust-free cloth dipped in alcohol, dry it with a hair dryer, and then treat it with ozone for 15 minutes; drop the prepared perovskite CH3NH3PbI3 precursor solution on the substrate Apply in a straight line, then scrape the solution with a scraper at a speed of 1m / min to form a uniform film, and let it dry at room temperature; anneal the film formed by scraping at 80°C for 20 minutes to form perovskite CH3NH3PbI3 micronanowire arrays. as attached Figure 1 The CH3NH3PbI3 micro-nanowire array formed by scraping coating on the ET substrate is shown, and Figure II The XRD results prove that the CH3NH3PbI3 crystals of mi...

Embodiment 2

[0028] Dissolve 150mg of CH3NH3I in 15ml of DMF, and stir for 2 minutes with a magnet; put 441mg of PbI2 into the DMF solution of CH3NH3I prepared, and stir for 1.5 hours at a constant temperature on a hot stage at 60°C to obtain a perovskite CH3NH3PbI3 precursor solution.

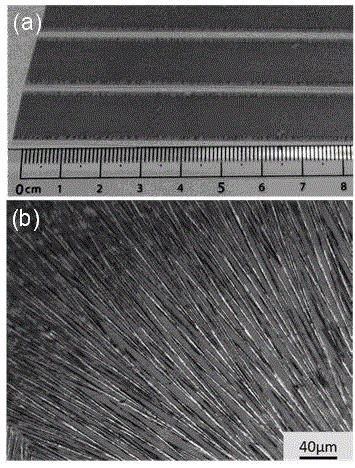

[0029] Referring to our previous roll-to-roll printing equipment invention patent (CN201420230074.X), the perovskite CH3NH3PbI3 solution was prepared by roll-to-roll microgravure printing. The width of the flexible PET substrate is 15cm, and the substrate speed is 0.5m / min. Printing preparation can form a uniform perovskite CH3NH3I film. After passing through a 70°C oven, it can self-assemble to form a CH3NH3PbI3 micro-nano wire array film, such as Figure four shown.

[0030] On the CH3NH3PbI3 micro-nano wire array prepared above, a mask plate with a channel length of 80 μm and a channel width of 1000 μm was used to cover the CH3NH3PbI3 micro-nano wire array film, and a layer of about 40 nm thick gold ele...

Embodiment 3

[0032] Dissolve 150mg of CH3NH3I in 15ml of DMF, and stir for 2 minutes with a magnet; put 262mg of PbCl2 into the prepared DMF solution of CH3NH3I, and stir at a constant temperature on a hot stage at 60°C for 2 hours to obtain a perovskite CH3NH3PbIxCl3-x precursor solution.

[0033] Referring to our previous roll-to-roll printing equipment invention patent (CN201420230074.X), the perovskite CH3NH3PbIxCl3-x solution was prepared by roll-to-roll slit coating printing. Printing preparation at a substrate speed can form a uniform perovskite CH3NH3PbIxCl3-x film. After passing through a 70°C oven, it can self-assemble to form a CH3NH3PbIxCl3-x micro-nano wire array film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com