Preparation method of composite of biochar-carbon nano-material

A carbon nanomaterial, biomass carbon technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the problem of increasing the cost of carbon nanomaterials and limiting carbon nanomaterials. Industrialization development and other issues, to achieve the effect of saving catalyst cost, realizing catalyst circulation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

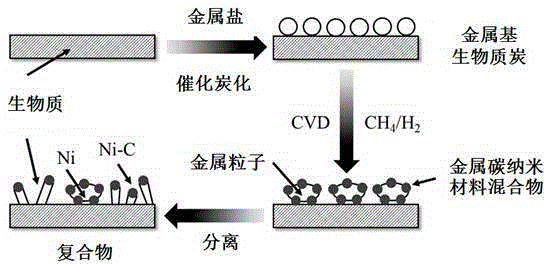

[0027] Use rice husk as biomass raw material, take quantitative rice husk and crush, add nickel nitrate according to the ratio of biomass:metal salt is 10:1, add appropriate amount of deionized water, stir for 3 hours at room temperature, and dry in a drying oven at 105°C . Take out the dried mixture, put it in the CVD furnace, feed nitrogen gas at a flow rate of 50ml / min, exhaust the air in the furnace, turn on the power, raise the temperature to 450°C at a heating rate of 20°C / min, and then turn it off Nitrogen, 100ml / min hydrogen was introduced to reduce the metal salt, the reduction time was 2h, then the hydrogen was turned off and the nitrogen was continued at the original rate.

[0028] On the basis of the above process, continue to raise the temperature to 800°C and keep it for 90min. After cooling down to 600°C, then according to CH 4 :N 2 =0.8:1 into the mixed gas, the flow rate of the mixed gas is 180ml / min, after 1 hour under this condition, the carbon source is ...

Embodiment example 2

[0030] Using corncobs as biomass raw materials, take quantitative corncobs and crush them, add ferric nitrate according to the ratio of biomass:metal salt is 10:1, add appropriate amount of deionized water, stir at room temperature for 3 hours, and dry in a drying oven at 105°C . Take out the dried mixture, put it in the CVD furnace, feed nitrogen gas at a flow rate of 50ml / min, exhaust the air in the furnace, turn on the power, raise the temperature to 500°C at a heating rate of 20°C / min, and then turn it off Nitrogen, 100ml / min hydrogen was introduced to reduce the metal salt, the reduction time was 2h, then the hydrogen was turned off and the nitrogen was continued at the original rate.

[0031] On the basis of the above process, continue to keep the temperature at 500°C for 90 minutes. After that, the temperature was raised to 600°C, and then according to CH 4 :H 2 :N 2 =1:1:2 into the mixed gas, the flow rate of the mixed gas is 200ml / min, after maintaining this condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com