Technology for recycling tailings through the process of weak magnetism concentration, roasting and regrinding magnetic separation

A technology for magnetic separation of tailings and concentrates, which is applied in recycling technology, mechanical material recovery, solid separation, etc., can solve the problems of difficulty in further improving the recovery rate, high tailings grade, and high energy consumption, and achieves improved grades and high efficiency. The effect of recycling and reducing the amount of disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

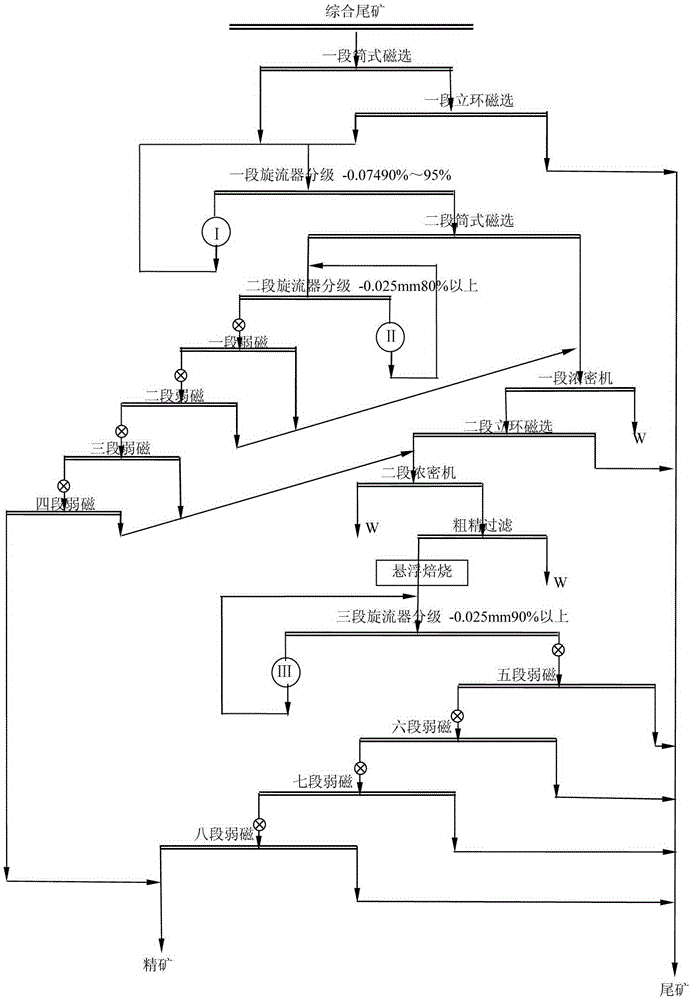

[0017] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] Such as figure 1 As shown, the weak magnetic concentration-roasting-regrinding magnetic separation tailings recovery process of the present invention includes feeding comprehensive tailings with a grade of 10% to 15% and a particle size of -0.074mm60% to 70% into a section of cylindrical magnetic Separator for magnetic separation operation, the tailings of a section of drum magnetic separator are fed into a section of vertical ring magnetic separator for magnetic separation operation, the concentrate of a section of drum magnetic separator and the concentrate of a section of vertical ring magnetic separator are combined to feed The closed-circuit grinding and classification operation composed of a section of cyclone and a section of ball mill, that is, the concentrate of a section of drum magnetic separator and the concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com