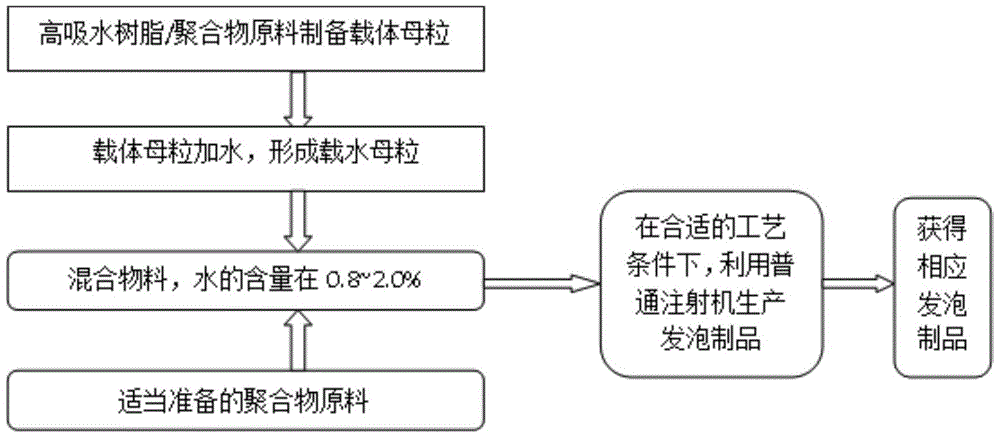

Water foaming injection method using superabsorbent resin as carrier

A technology of superabsorbent resin and water foaming, applied in the field of processing and manufacturing of polymer materials, can solve the problems of limited water-carrying capacity of activated carbon, difficulty in controlling the color of products, and easy adsorption to the periphery of equipment, etc., to reduce equipment operating costs, The effect of reducing the internal stress of the product and the process of water absorption is simple and rapid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

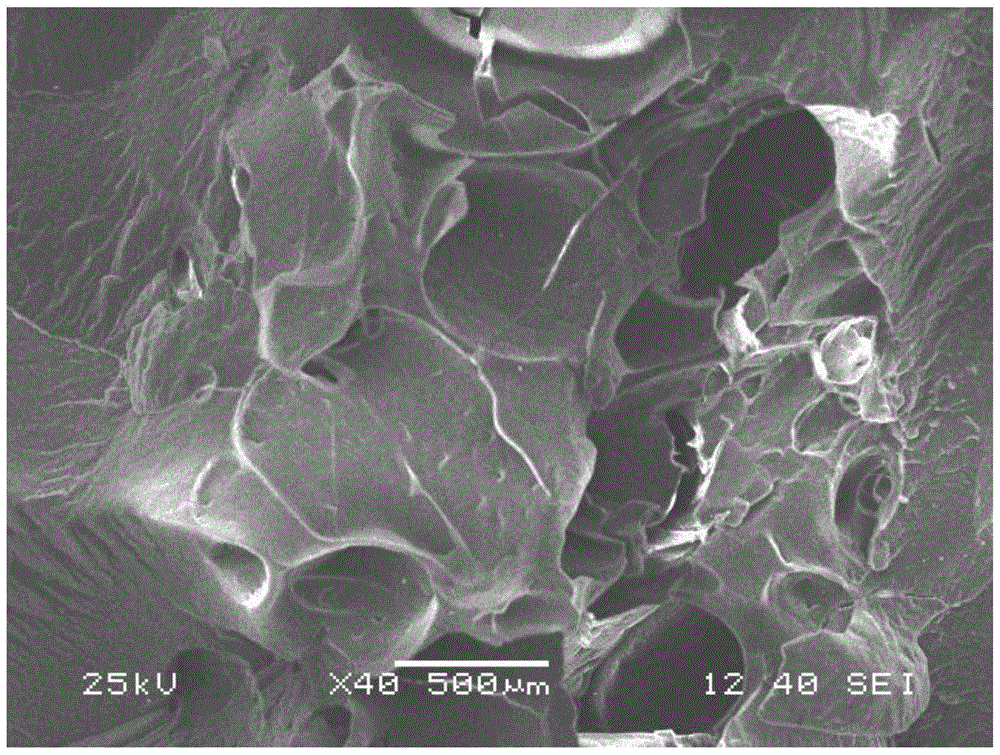

Examples

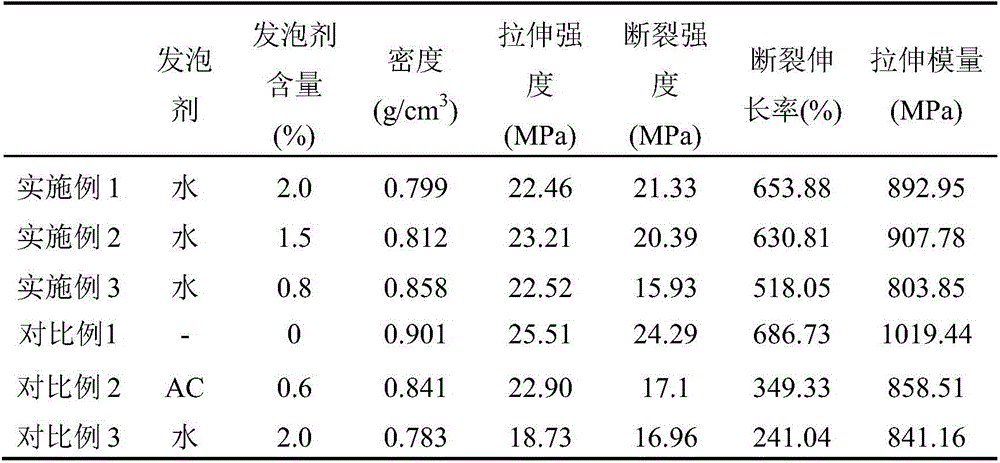

Embodiment 1

[0042] PP (polypropylene) is used as the material to be processed, and LDPE is used as the base material. Among them, the PP used is domestic commercially available T30S with a melt flow index of 3.2g / 10min (230°C, 21.6N), and the LDPE used is domestically available commercially available 951-000 with a melt flow index of 2.18g / 10min .

[0043] First, the carrier masterbatch is manufactured. Dry the superabsorbent resin in a drying oven at 50°C for half an hour to remove water, and then weigh the raw materials according to the following weights: superabsorbent resin: 0.1kg, LDPE: 0.9kg, the mass ratio of the two is 1:9. After the superabsorbent resin and LDPE raw materials were mixed and placed in a humid environment for 24 hours, the weight was said to be 1002g. Then the mixed material is passed through an ordinary plastic extruder to obtain a carrier masterbatch, and the melt temperature is controlled to be 160°C during the extrusion process; the prepared carrier masterbat...

Embodiment 2

[0050] PP is used as the material to be processed, and LDPE is used as the base material. Among them, the PP used is domestic commercially available T30S with a melt flow index of 3.2g / 10min (230°C, 21.6N), and the LDPE used is domestically available commercially available 951-000 with a melt flow index of 2.18g / 10min .

[0051] First, the carrier masterbatch is manufactured. Dry the superabsorbent resin in a drying oven at 50°C for half an hour to remove possible moisture, and then weigh the raw materials according to the following weights: superabsorbent resin: 0.05kg, LDPE: 0.95kg, the mass ratio of the two is 1 :19. After the superabsorbent resin and LDPE raw materials were mixed and placed in a humid environment for 48 hours, the weight was said to be 1001.3g. Then the mixed material is passed through an ordinary plastic extruder to obtain a carrier masterbatch, and the melt temperature is controlled to be 160°C during the extrusion process; the prepared carrier master...

Embodiment 3

[0057] PP is used as the material to be processed, and LDPE is used as the base material. Among them, the PP used is domestic commercially available T30S with a melt flow index of 3.2g / 10min (230°C, 21.6N), and the LDPE used is domestically available commercially available 951-000 with a melt flow index of 2.18g / 10min .

[0058] First, the carrier masterbatch is manufactured. Dry the superabsorbent resin in a drying oven at 50°C for half an hour to remove possible moisture, and then weigh the raw materials according to the following weights: superabsorbent resin: 0.05kg, LDPE: 0.95kg, the mass ratio of the two is 1 :19. After the superabsorbent resin and LDPE raw materials were mixed and placed in a humid environment for 24 hours, the weight was said to be 1001g. Then the mixed material is passed through an ordinary plastic extruder to obtain a carrier masterbatch, and the melt temperature is controlled to be 160°C during the extrusion process; the prepared carrier masterba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com