Spark plug paper cover forming machine with material cutting mechanism

A technology of spark plugs and molding machines, which is applied to cardboard items, etc., can solve the problems of poor consistency in cutting dimensions, poor product processing consistency, and low processing efficiency, and achieve high molding processing efficiency, good molding consistency, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is specifically described below by the embodiment, only for further illustrating the present invention, can not be interpreted as the limitation of protection scope of the present invention, the technical engineer of this field can make some non-essential improvements and improvements to the present invention according to the content of the above-mentioned invention Adjustment.

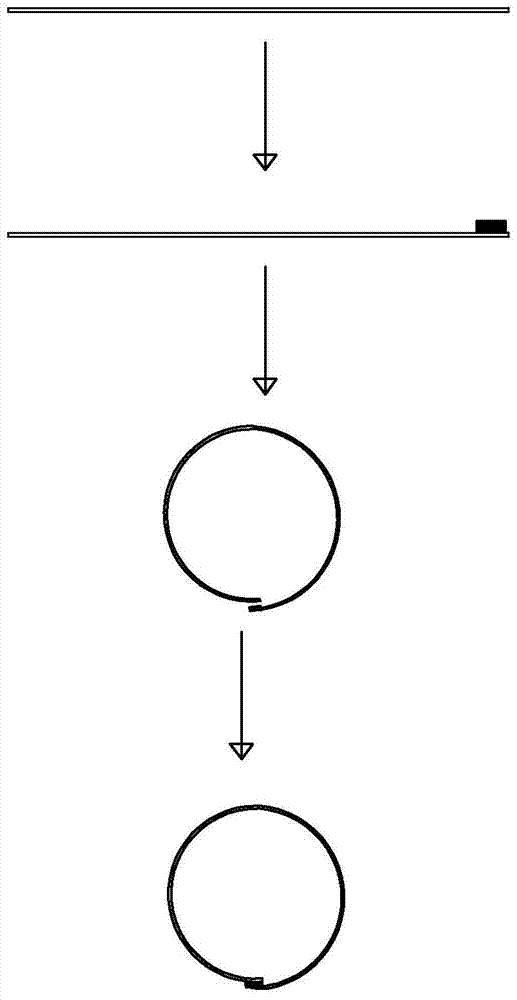

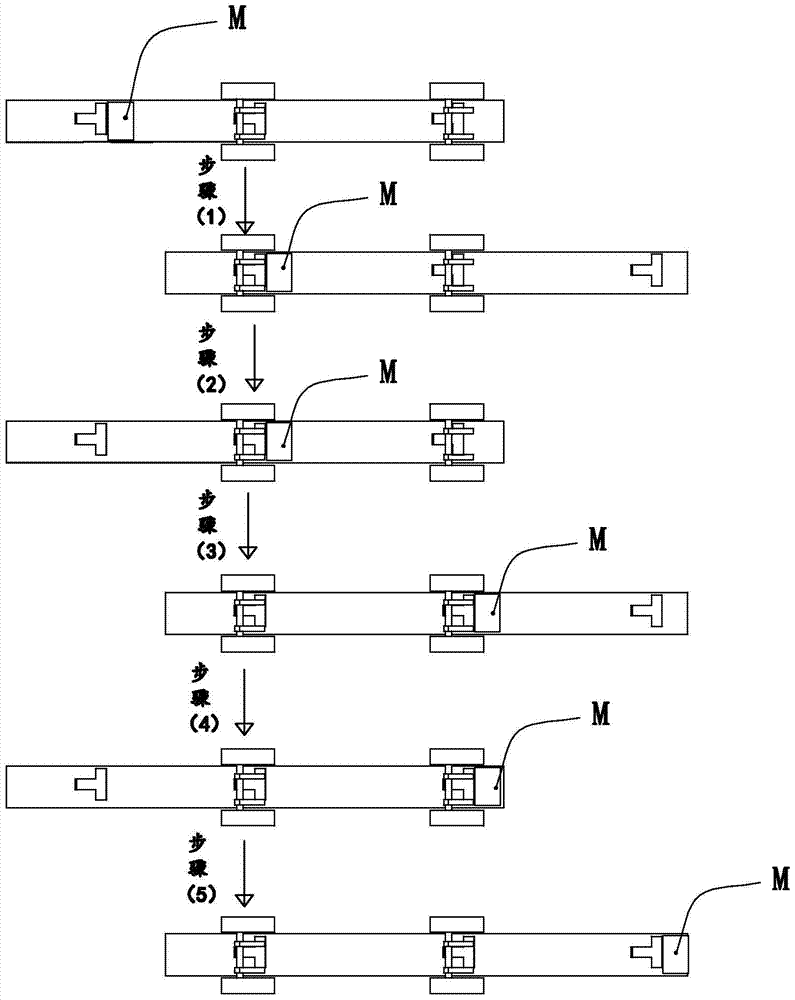

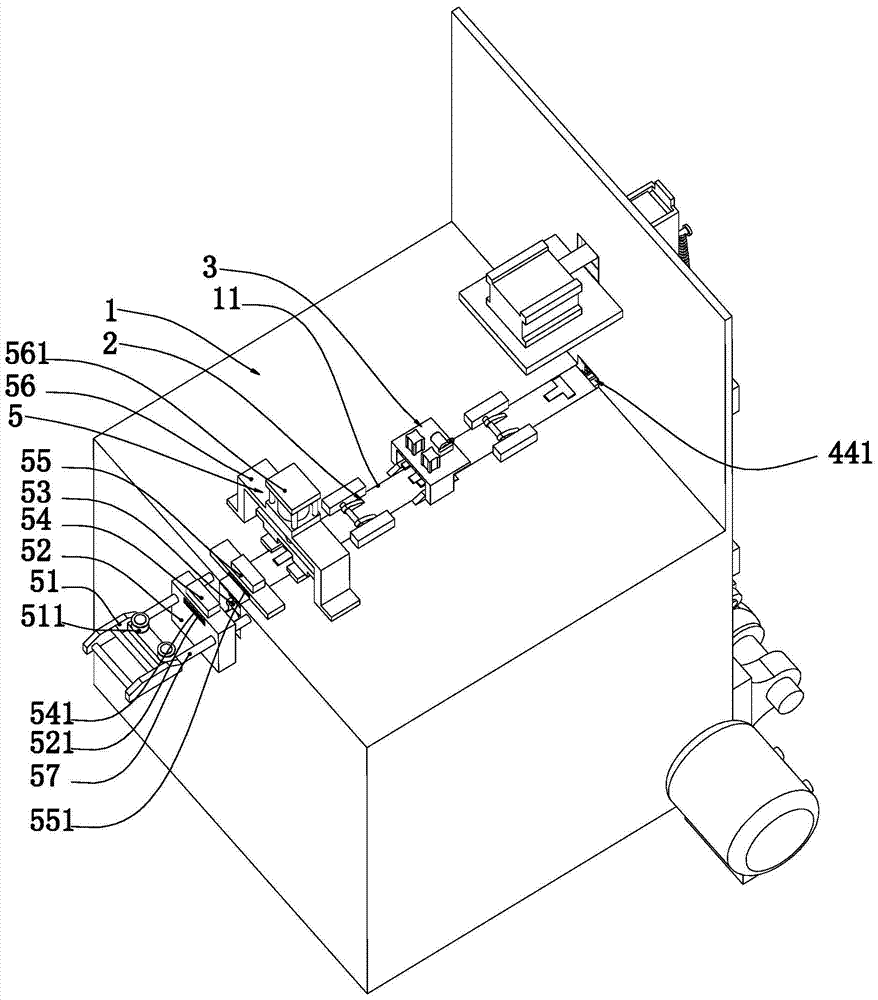

[0041] Such as Figure 1-12 The specific embodiment of the present invention shown includes a frame 1 , a feeding mechanism 2 , an edge gluing mechanism 3 and a circle-hugging and edge-drying mechanism 4 .

[0042] The material cutting mechanism 5 described in this embodiment includes a material guide frame 51, a feed frame 52, a feed frame driving cylinder 53, a first pressing cylinder 54, a second pressing cylinder 55 and a cutter frame 56. The side of the frame 1 is provided with a pair of feed guide rods 57 parallel to each other, the guide frame 51 is fixedly arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com