High partial discharge voltage solar battery back board base film and preparation method thereof

A technology for solar cells and backplane base films, which can be used in chemical instruments and methods, lamination, electronic equipment, etc., and can solve problems such as insufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

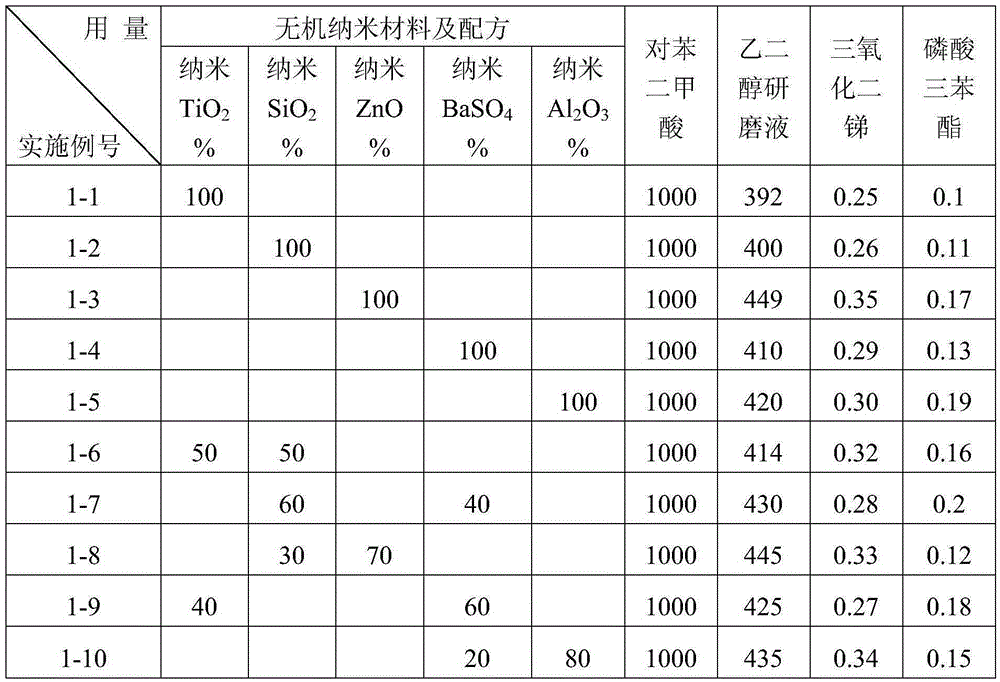

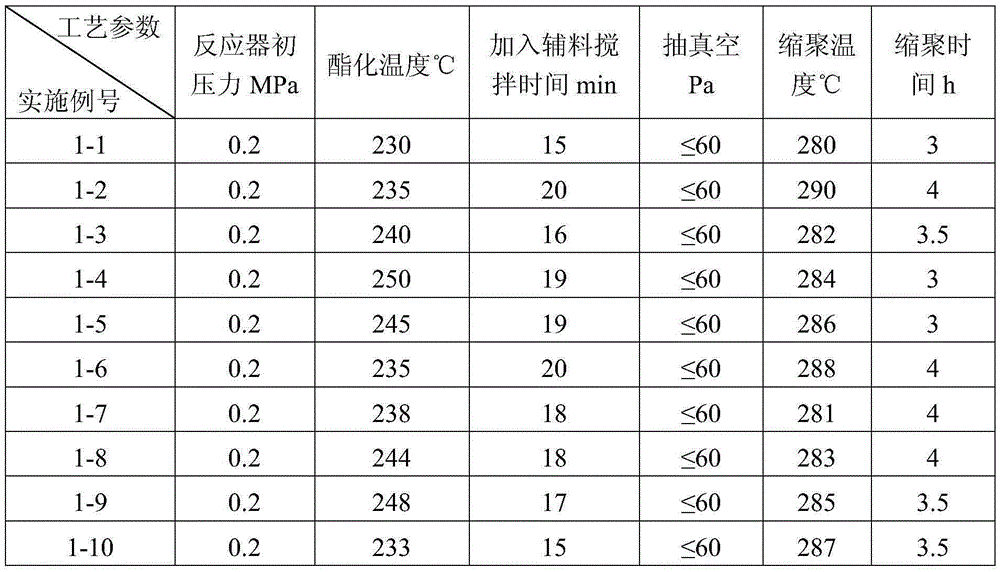

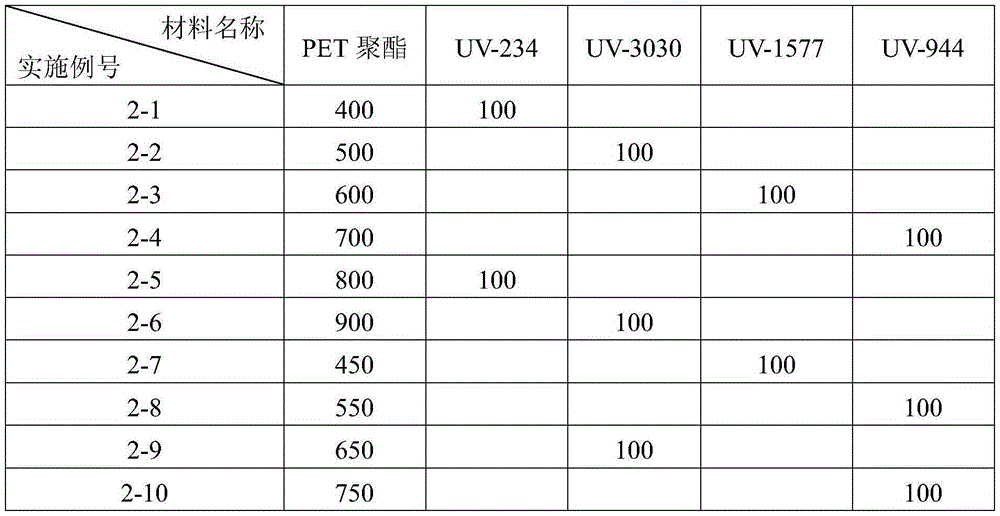

Method used

Image

Examples

preparation example Construction

[0078] Part VI Preparation of Hydrolysis-resistant PET Resin

[0079] Basic process: Mix 1 mass part of the hydrolysis-resistant PET masterbatch prepared in Examples 3-1 to 3-10 and 9 to 99 mass parts of PET polyester resin with an intrinsic viscosity of 0.60dl / g to 0.85dl / g, and mix evenly in After drying at a drying temperature of 150°C to 170°C for 2h to 4h, extrude through twin-screw extruder 4# at a temperature of 265°C to 285°C, pelletize, and set aside.

[0080] The formulation and dosage of the hydrolysis-resistant PET resin prepared in Examples 5-1 to 5-10 are shown in Table 6 below:

[0081] Table 6: Formulation table of the hydrolysis-resistant PET resin of Examples 5-1 to 5-10 (unit: ㎏)

[0082]

[0083] Note: The hydrolysis-resistant PET masterbatches in Examples 3-1 to 3-10 are used in sequence for each example in Examples 5-1 to 5-10 in the above table.

[0084] Part VII Preparation of Base Film for High PD Voltage Solar Cell Backplane

[0085] Basic proce...

Embodiment 7

[0094] A high partial discharge voltage solar battery backplane base film, the high partial discharge voltage solar battery backplane base film is composed of A-layer polyester film with high partial discharge voltage function and B-layer polyester film with hydrolysis resistance function , the mass ratio of the A-layer polyester film to the B-layer polyester film is 400:100, and the thickness of the base film of the high partial discharge voltage solar cell backplane is 100 μm;

[0095] The high partial discharge voltage solar battery backplane base film is made by passing 400 parts by mass of the high partial discharge voltage PET resin for the A layer and 100 parts by mass of the hydrolysis-resistant PET resin for the B layer through two extruders at 260° C. After melting, it is extruded by layered co-extrusion through a resin melt distributor, cast on a cold drum at 15°C, then stretched 2.9 times in the longitudinal direction and 3.0 times in the transverse direction, and h...

Embodiment 8

[0102] A high partial discharge voltage solar battery backplane base film, the high partial discharge voltage solar battery backplane base film is composed of A-layer polyester film with high partial discharge voltage function and B-layer polyester film with hydrolysis resistance function , the mass ratio of the A-layer polyester film to the B-layer polyester film is 900:100, and the thickness of the base film of the high partial discharge voltage solar cell backplane is 350 μm;

[0103] The high partial discharge voltage solar battery backplane base film is made by passing 900 parts by mass of the high partial discharge voltage PET resin for the A layer and 100 parts by mass of the hydrolysis-resistant PET resin for the B layer through two extruders at 290° C. After melting, it is extruded by layered co-extrusion through a resin melt distributor, cast on a cold drum at 25°C, and then stretched 3.5 times in the longitudinal direction and 3.5 times in the transverse direction, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com