PVA (Poly Vinyl Alcohol) modified antimony trioxide and preparation method thereof

A technology of antimony trioxide and polyvinyl alcohol, which is applied in the treatment of dyed polymer organic compounds, fibrous fillers, etc., can solve the problems of high specific gravity, poor dispersion and large particle size of flame retardant antimony trioxide. Achieve good similar compatibility, small intermolecular distance, and enhanced mechanical riveting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

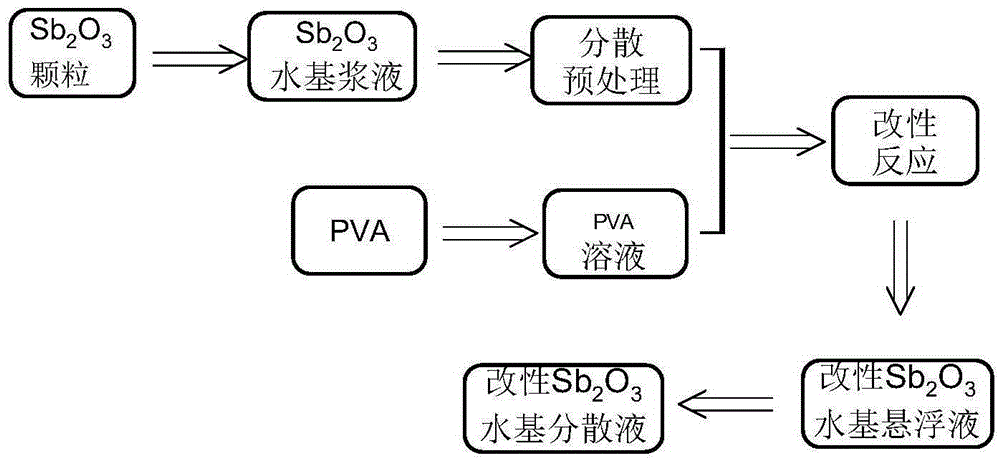

Method used

Image

Examples

Embodiment 1

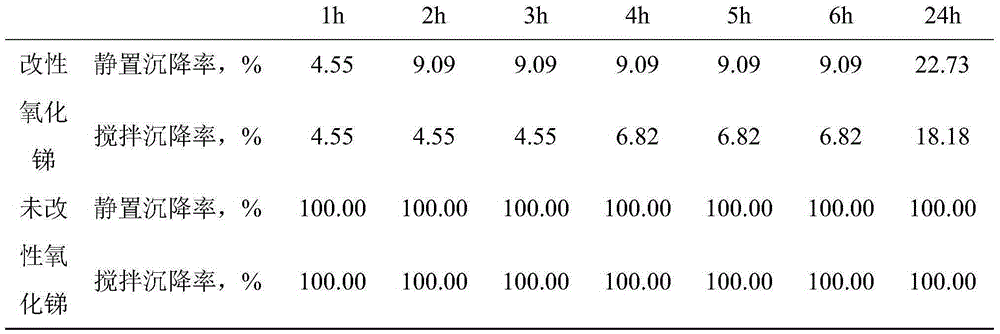

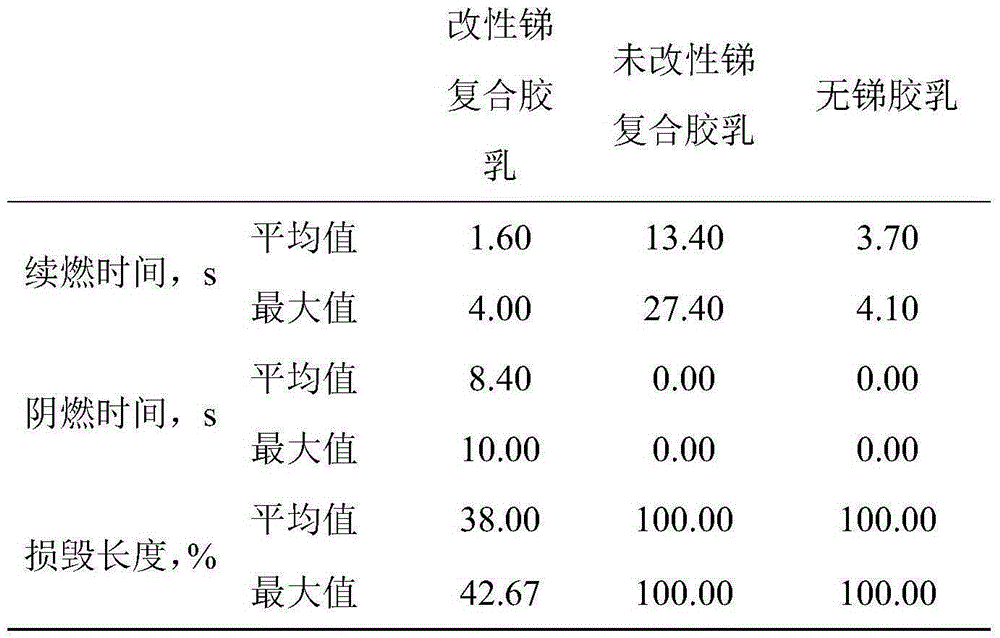

[0033] The antimony trioxide powder with a particle size of 0.5-5 μm is added into distilled water, and the powder is mechanically stirred to prepare a 30% antimony trioxide slurry. Put the antimony trioxide slurry into the ultrasonic generator, the ultrasonic power is 200-600W, the working frequency is 20-40kHz, and the ultrasonic wave is irradiated for 15min. The polyvinyl alcohol was added to the container, then distilled water was added, and the solution was heated and stirred for 20 minutes at 90° C. to prepare a 10% concentration polyvinyl alcohol solution. In the container, the polyvinyl alcohol solution is firstly added, and then the pretreated antimony trioxide slurry is added, and the mass ratio is 3:100, and the dry basis ratio is 1:100. Then, under the condition of 100° C., the reaction is stirred at a high speed for 20 minutes to prepare an active antimony trioxide water-based suspension, and the mass concentration of the antimony trioxide suspension is about 30%....

Embodiment 2

[0035] The antimony trioxide powder with a particle size of 0.5-5 μm is added into distilled water, and the powder is mechanically stirred to prepare a 40% antimony trioxide slurry. Put the antimony trioxide slurry into the ultrasonic generator, the ultrasonic power is 200-600W, the working frequency is 20-40kHz, and the ultrasonic wave is irradiated for 30min. The polyvinyl alcohol was added to the container, then distilled water was added, and the solution was heated and stirred for 30 minutes at 90° C. to prepare a 10% concentration polyvinyl alcohol solution. In the container, the polyvinyl alcohol solution is firstly added, and then the pretreated antimony trioxide slurry is added, and the mass ratio is 20:100 and the dry basis ratio is 5:100. Then, under the condition of 60° C., high-speed stirring reaction was performed for 40 minutes to prepare a polyvinyl alcohol-modified antimony trioxide water-based suspension, and the mass concentration of the antimony trioxide sus...

Embodiment 3

[0037]The antimony trioxide powder with a particle size of 0.5-5 μm is added into distilled water, and the powder is mechanically stirred to prepare a 25% antimony trioxide slurry. Put the antimony trioxide slurry into the shearing emulsification tester, rotate speed 3000r / min, shear and stir for 15min. The polyvinyl alcohol was added to the container, then distilled water was added, and the solution was heated and stirred for 40 minutes at 90° C. to prepare a 10% concentration polyvinyl alcohol solution. In the container, the polyvinyl alcohol solution is firstly added, and then the pretreated antimony trioxide slurry is added, the mass ratio of which is 7.5:100, and the dry basis ratio is 3:100. Then, under the condition of 90° C., the reaction is carried out with high-speed stirring for 30 minutes to prepare a polyvinyl alcohol-modified antimony trioxide water-based suspension, and the mass concentration of the antimony trioxide suspension is about 24%. Weigh a certain amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com