A kind of nano water-based paint with waterproof, anti-scratch and anti-fingerprint properties and its preparation method and application

A water-based coating, anti-fingerprint technology, applied in the direction of coating, etc., can solve the problems of economic loss, poor water vapor resistance, non-isolated contact points, etc., and achieve the effect of uniform distribution of doping, good chemical uniformity, and easy control of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The nano water-based paint with waterproof, anti-scratch and anti-fingerprint properties described in this embodiment is made from the raw materials of the following mass ratios:

[0032] Silicon dioxide: silicon carbide: calcium fluoride: complexing agent: tetrafluoropropanol = 6:1:1:0.125:75.

[0033] The preparation technology of nano water-based coating described in the present embodiment, comprises the following steps:

[0034] (1) Using the Gel-Sol method to separate SiO 2 , SiC and CaF 2 Prepared into inorganic nanomaterials;

[0035] (2) Adjust the speed of the disperser to 300r / m, and slowly add SiO 2 , SiC and CaF 2 Add appropriate amount of tetrafluoropropanol, so as not to make the viscosity of the slurry too high and inconvenient to use. Depending on the viscosity of the overall slurry, add an appropriate amount of tetrafluoropropanol, and then add a complexing agent to form gel solution;

[0036] (3) Evaporating water from the gel solution in step (2...

Embodiment 2

[0038] The nano water-based paint with waterproof, anti-scratch and anti-fingerprint properties described in this embodiment is made from the raw materials of the following mass ratios:

[0039] Silicon dioxide: silicon carbide: calcium fluoride: complexing agent: isopropanol=9.25:3.25:2.25:0.25:85.

[0040] The preparation technology of nano water-based coating described in the present embodiment, comprises the following steps:

[0041] (1) Using the Gel-Sol method to separate SiO 2 , SiC and CaF 2 Prepared into inorganic nanomaterials;

[0042] (2) Adjust the speed of the disperser to 400r / m, and slowly add SiO 2 , SiC and CaF 2 Add an appropriate amount of isopropanol to prevent the viscosity of the slurry from being too high and inconvenient to use. Depending on the viscosity of the overall slurry, add an appropriate amount of isopropanol, and then add a complexing agent to form a gel. solution;

[0043] (3) Evaporating water from the gel solution in step (2) in a va...

Embodiment 3

[0046] The nano water-based paint with waterproof, anti-scratch and anti-fingerprint properties described in this embodiment is made from the raw materials of the following mass ratios:

[0047] Silicon dioxide: silicon carbide: calcium fluoride: complexing agent: isopropanol = 12:7:5:0.5:95.

[0048] The preparation process of the nano water-based paint described in this embodiment is the same as that in Example 2.

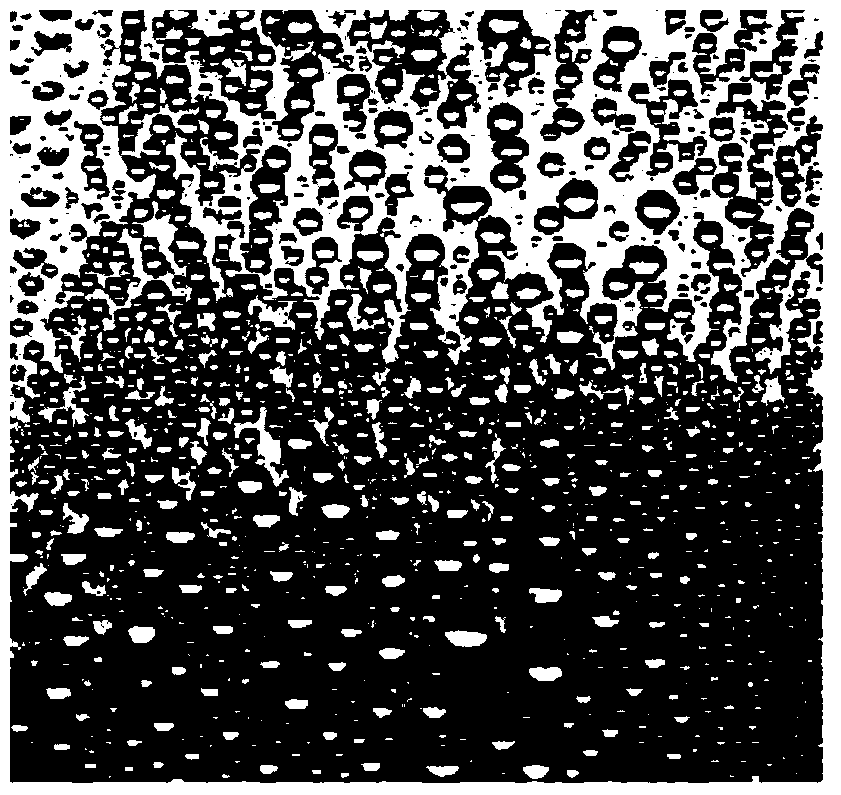

[0049] Such as figure 2 Shown is the waterproof effect diagram of the nano water-based coating of the present invention. figure 2 Among them, the mobile phone screen is coated with the nanometer water-based coating of this embodiment 2, and a little pure water is sprayed on the coating, and it is found that the water and the coating are not wet, and the water exists in the form of water droplets on the coating, and the contact angle is 104 degrees. It shows that the coating has a good waterproof effect.

[0050] Such as image 3Shown is the anti-scratch eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com