Rare-earth upconversion luminescent nanosphere having hollow core-shell structure as well as preparation method and use of nanosphere

A technology of rare earth up-conversion and core-shell structure, which is applied in the field of hollow core-shell structure rare earth up-conversion luminescent nanospheres and its preparation, can solve the problems of cumbersome steps, poor dispersion, and easy aggregation of particles, and achieve a simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

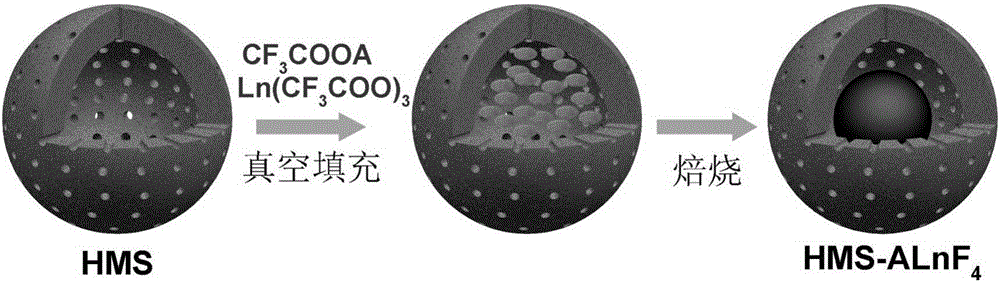

[0046] As mentioned above, in order to solve the cumbersome steps in the preparation of rare earth up-conversion luminescent nanospheres with hollow core-shell structure in the prior art using the method of "core first and then shell", a large amount of high-boiling organic solvents are required for the synthesis of nanocrystals, and the size of the final luminescent nanospheres Due to problems such as limited adjustable range, the present invention provides a method for preparing rare earth up-conversion luminescent nanospheres with a hollow core-shell structure, such as figure 1 As shown, the method includes the following steps:

[0047] (1) preparing hollow mesoporous silica nanospheres;

[0048] (2) introducing the precursor of the rare earth-doped ternary fluoride into the cavity of the hollow mesoporous silica nanosphere prepared in step (1);

[0049] (3) Calcining the mesoporous silica nanospheres filled with precursors in the cavity, so that the precursors can generat...

Embodiment 1

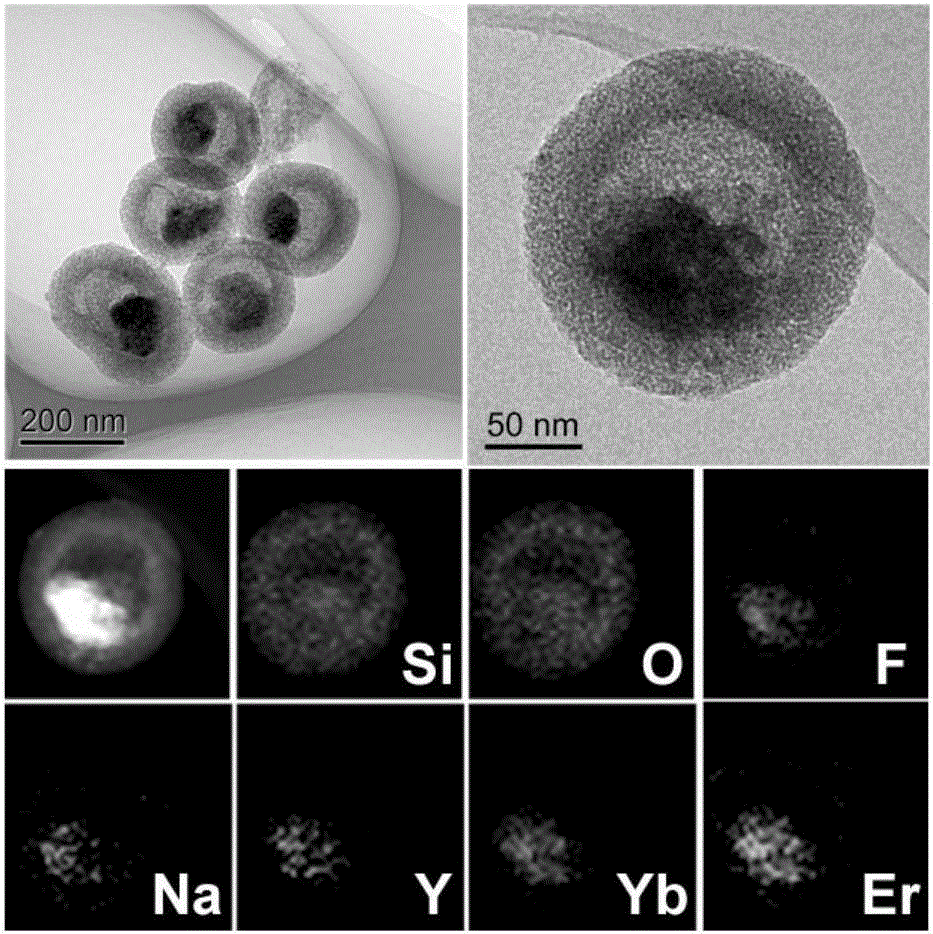

[0074] Preparation of Luminescent Nanosphere HMS-NaYF with a Size of 200nm 4 :Yb / Er

[0075] (1) A cationic surfactant-assisted selective etching method (Nanoscale, 2011, 3, 1632) was used to prepare hollow inorganic mesoporous silica nanosphere solid powder with a size of 200 nm and a shell thickness of 35 nm. Its specific surface area is 318cm 2 / g, the pore volume is 0.5cm 3 / g.

[0076] (2) Under vacuum conditions, 5mL of CF 3 COONa, Y(CF 3 COO) 3 , Yb(CF 3 COO) 3 and Er(CF 3 COO) 3 The mixed solution (the concentration of the mixed solution is 1.05mmol / L, the molar ratio of each element is Y:Na:Yb:Er=0.78:2.5:0.2:0.02) is injected into 25mg of the hollow inorganic medium prepared in the above step (1). Porous silica nanosphere solid powder, stirred for 1 hour, continued to stir for 1 hour after removing the vacuum, collected the solid after centrifugation, and dried overnight at 110° C. to obtain a dry solid.

[0077] (3) Put the dry solid obtained in step (2) ...

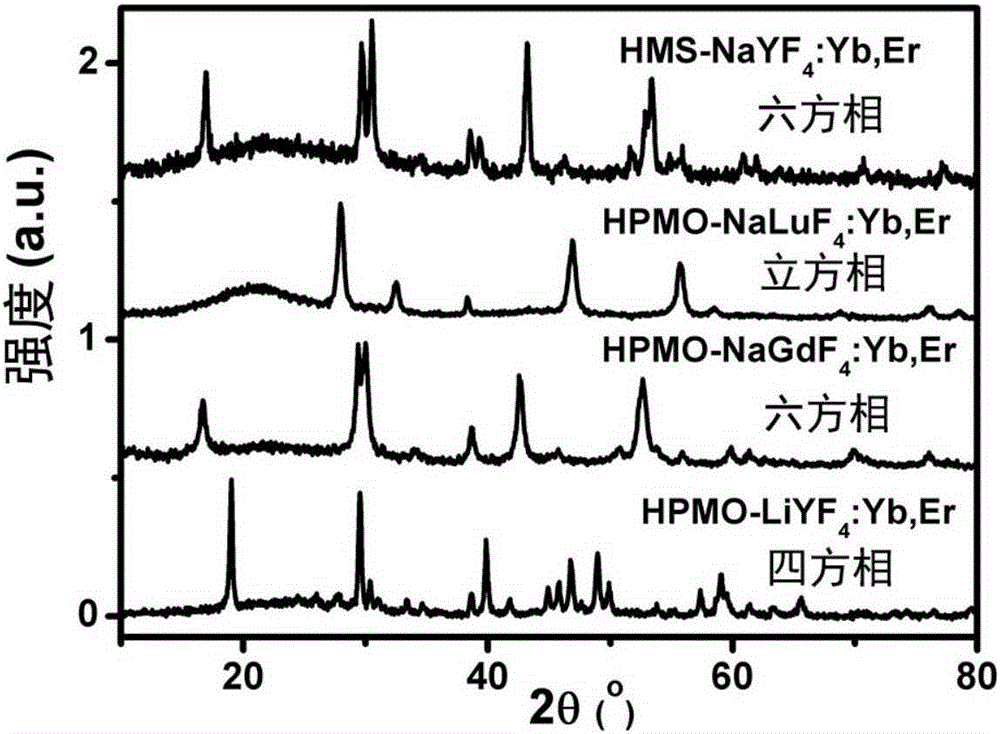

Embodiment 2

[0083] Preparation of Luminescent Nanosphere HPMO-NaLuF with a Size of 80nm 4 :Yb / Er

[0084] (1) Use the polymer bead template method (J.Mater.Chem., 2012,22,17636), and replace it with a mixture of 1,4-bis(triethoxysilyl)benzene and aminopropylethoxysilane Ethyl orthosilicate, and a hollow organic mesoporous silica nanosphere solid powder with a size of 80nm and a shell thickness of about 15nm was prepared. 13 C and 29 Si solid NMR confirmed its organosilicon composition (such as Figure 5 ).

[0085] (2) Under vacuum conditions, 2mL of CF 3 COONa, Lu(CF 3 COO) 3 , Yb(CF 3 COO) 3 and Er(CF 3 COO) 3 The mixed solution (concentration is 0.9mmol / L, the molar ratio of each element is Gd:Na:Yb:Er=0.78:2.5:0.2:0.02) is injected into 10mg of hollow organic mesoporous silica prepared in step (1) In the nanosphere solid powder, stir for 0.5 hour, and continue to stir for 6 hours after removing the vacuum. The solid was collected after centrifugation and dried overnight at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com