Functional coating of pure silver layer/pure-graphite composite layer and preparation method of functional coating

A silver-graphite, functional technology, applied in the field of electrical contact protection materials, can solve problems such as failure, decreased conductivity of pure silver coating, and difficulty in uniform dispersion, and achieves high efficiency in production process, excellent comprehensive performance, and great application value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

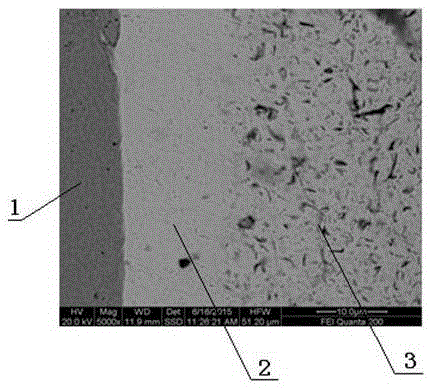

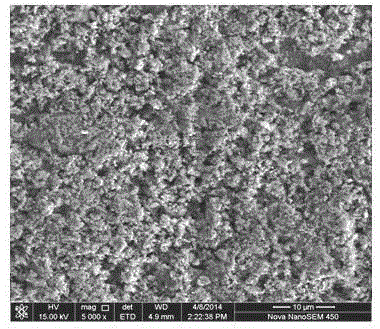

Image

Examples

Embodiment 1

[0021] (1) Configuration of electroplating solution:

[0022] The main components of the pre-silvering solution are: Ag + 0.5g / L, KCN60g / L, K 2 CO 3 12g / L, pH 10; the main components of the silver plating solution are: Ag + 20g / L, KCN40g / L, K 2 CO 3 20g / L, pH 10; the main components of the silver-graphite composite plating solution are: Ag + 20g / L, KCN20g / L, K 2 CO 3 20g / L, dispersant 15ml / L, auxiliary agent 15ml / L, graphite powder 50g / L, pH value 10.

[0023] (2) Electroplating:

[0024] Surface treatment of base material: Put the base material polished by sandpaper into the degreasing solution. After power on, adopt the combined degreasing method of cathode first and then anode. The cathode degreasing time is 30s, the anode degreasing time is 10s, and repeat once Combined degreasing of the rear anode; the base material after degreasing is soaked in deionized water at 60°C and shaken up and down for 5s, and then the base material is soaked in deionized water at room ...

Embodiment 2

[0035] (1) Configuration of electroplating solution:

[0036] The main components of the pre-silvering solution are: Ag + 1g / L, KCN50g / L, K 2 CO 3 12g / L, pH value 11; the main component of the silver plating solution is: Ag + 25g / L, KCN60g / L, K 2 CO 3 25g / L, pH value 11; the main components of the silver-graphite composite plating solution are: Ag + 25g / L, KCN75g / L, K 2 CO 3 25g / L, dispersant 20ml / L, auxiliary agent 20ml / L, graphite powder 70g / L, pH value 11.

[0037] (2) Electroplating:

[0038]Surface treatment of base material: Put the base material polished by sandpaper into the degreasing solution. After power on, adopt the combined degreasing method of cathode first and then anode. The degreasing time of cathode is 40s, and the degreasing time of anode is 40s. Combined degreasing of the rear anode; the base material after degreasing is soaked in 70°C deionized water and shaken up and down for 15s, and then the base material is soaked in deionized water at room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com