Special soil subgrade structure and construction method thereof

A special soil and soil subgrade technology, applied to roads, roads, buildings, etc., can solve the problems of composite geomembrane damage, insufficient composite geomembrane width, difficult to seal the subgrade, etc., and achieve the effect of improving ecological damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail

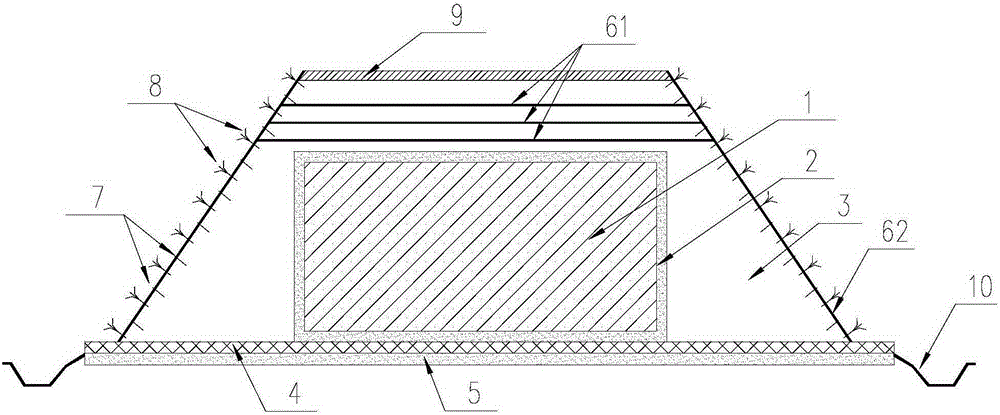

[0038] see figure 1, an expansive soil subgrade structure, the expansive soil filling layer includes expansive soil 1, composite soil 2 with bamboo silk added, cohesive soil 3, crushed stone cushion 4 and composite soil bottom layer 5, and the composite soil bottom layer 5 is set At the bottom of the roadbed structure, the crushed stone cushion 4 is laid on the composite soil bottom layer 5, the expansive soil 1 is arranged on the crushed stone cushion 4, and is completely wrapped by the composite soil 2 added with bamboo silk, so that The cohesive soil 3 described above is covered on the side and top of the expansive soil 1 wrapped by the composite soil 2 added with bamboo filaments to form a roadbed shape, and the top of the cohesive soil 3 is paved with a road surface.

[0039] In order to strengthen the stability of the subgrade structure, a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com