Interior wall diatom mud coating and coating method

A diatom mud coating and diatom mud technology, applied in covering/lining, building, building structure, etc., can solve the problems of poor sound insulation effect, inability to purify indoor air, eliminate peculiar smell, etc. Strong, high-end and beautiful finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

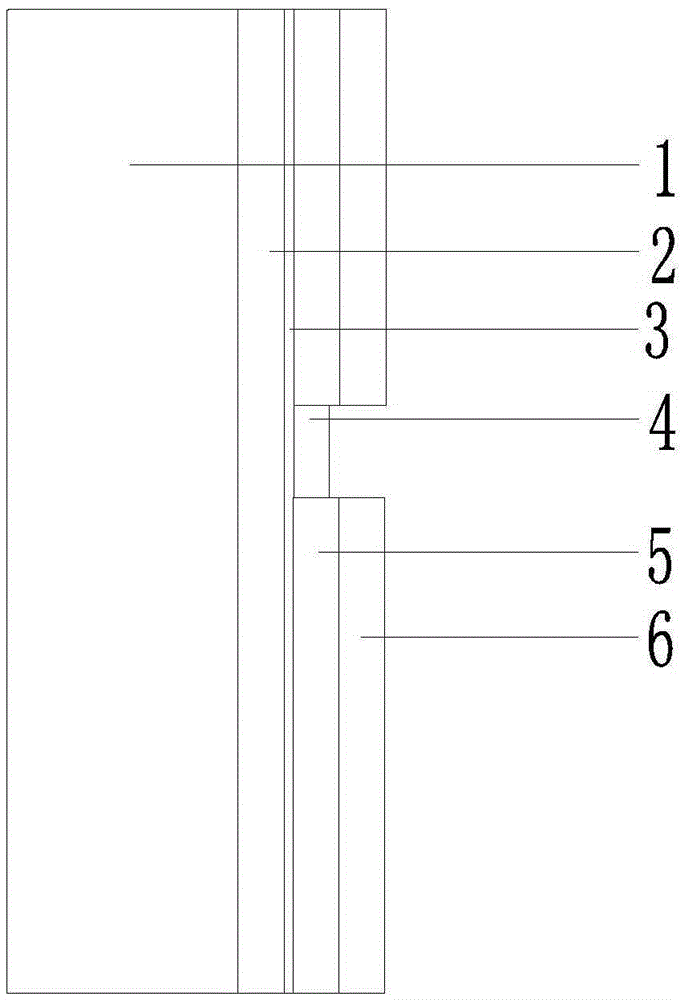

[0019] Example 1 as figure 1 As shown, a diatom ooze coating for an interior wall described in the embodiment of the present invention has a six-layer structure, which is sequentially as follows from the inside to the outside: an internal putty layer 2, a primer layer 3, and a paint layer for a grid. 4. The bottom layer of diatom mud coating 5. The surface layer of diatom mud coating 6. Wherein the putty layer 3 trims the base material to make the whole coating smooth and beautiful; the primer layer 3 effectively prevents the alkaline substance of the base material and the putty layer 2 from migrating to the coating surface and causes the paint film to fall off; the diatom mud coating bottom layer 5 Provide a base color and further increase the flatness of the wall; the diatom mud coating surface layer 6 provides floating points to enhance the three-dimensional effect of the coating, and at the same time, the formation of convex and concave surfaces is more conducive to the co...

Embodiment 2

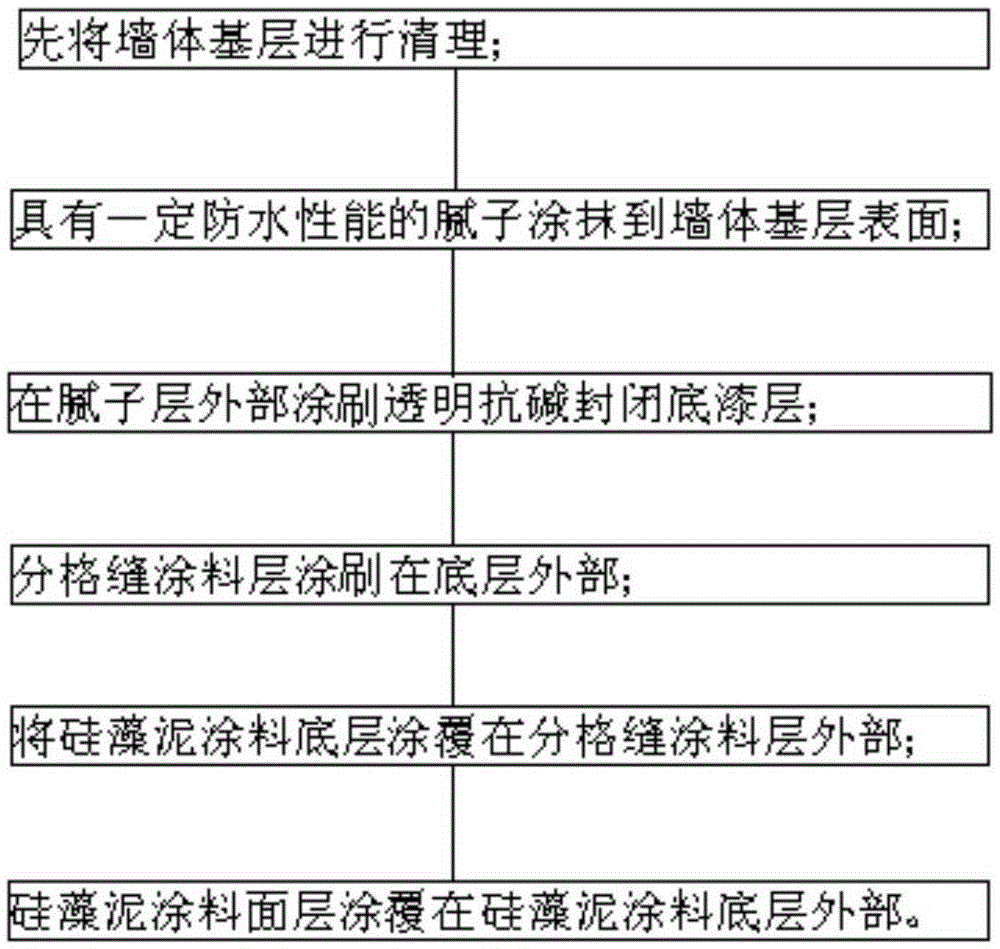

[0020] Example 2 as figure 2 Shown, a kind of coating method of interior wall diatom ooze coating, this method may further comprise the steps:

[0021] Before painting, the base layer of the wall must be treated to make it solid, flat, dry, free of floating dust, and free of oil.

[0022] After the treatment of the base layer of the wall is completed, the waterproof putty for the inner wall should be scraped. It is necessary to select a product with reliable quality and prepare it on site according to the water-cement ratio specified by the manufacturer. Stir it evenly before using it. Depending on the flatness and roughness of the substrate, scrape 2-3 times. After drying, smooth the surface of the putty with sandpaper.

[0023] After the putty is dry, apply an anti-alkali primer. You can choose YG-1100 transparent anti-alkali primer. It must be applied once and cannot be missed.

[0024] After the primer is dry, make the grid joint according to the position and size requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com