Device and method for testing gas diffusion coefficient in porous medium

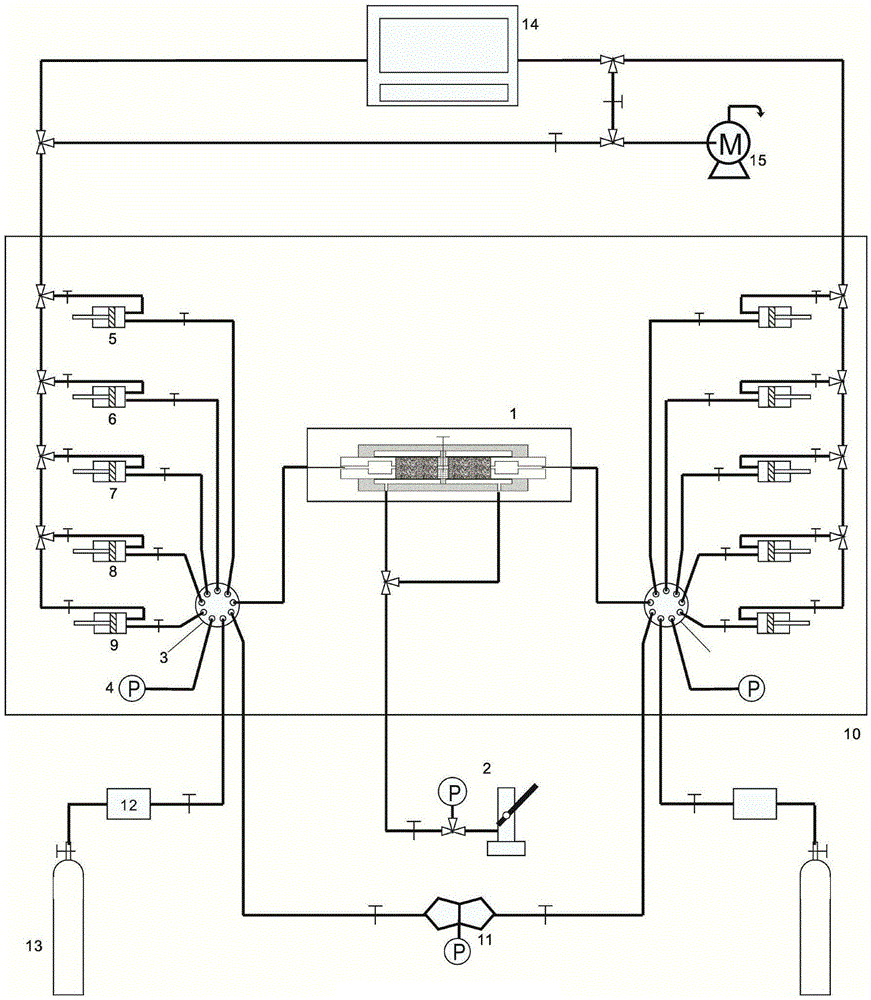

A technology of porous media and gas diffusion, which can be used in measuring devices, instruments, scientific instruments, etc., and can solve the problems of test result error, pressure disturbance and influence of gas chambers at both ends of porous media, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

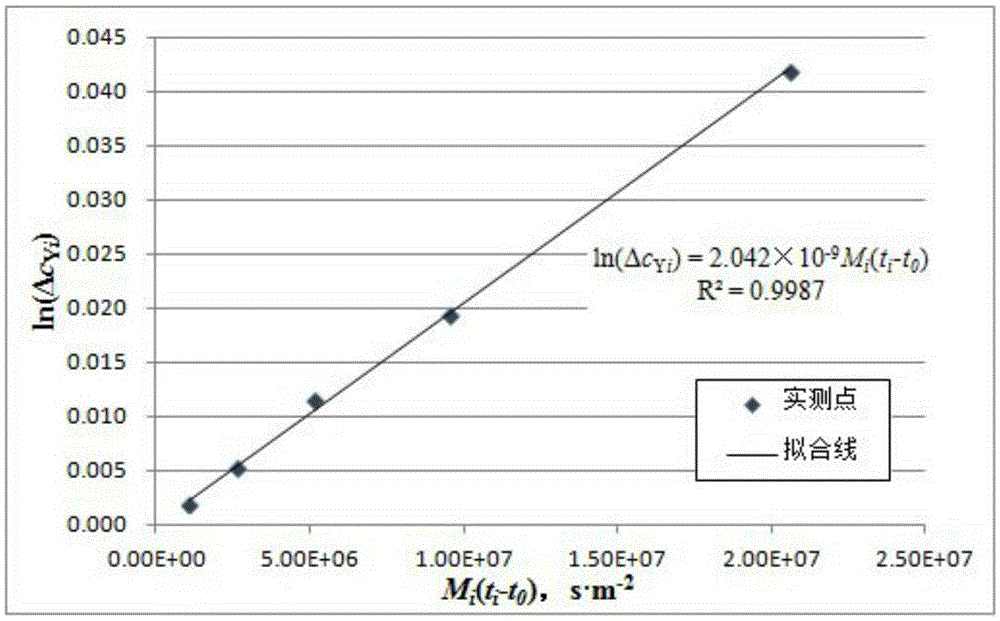

[0057] Use the test device for gas diffusion coefficient in the porous medium to test CO 2 With CH 4 When CH diffuses in formation rock 4 The diffusion coefficient of is for CO injection in a tight sandstone gas reservoir in a gas field 2 Increase gas reservoir natural gas (CH 4 ) The recovery factor study provides basic parameters. The temperature and pressure of the gas reservoir’s destination layer are 77°C and 21.6MPa, respectively. The detailed steps are as follows:

[0058] A) The evacuation process of connecting the device and the internal pores of the porous medium sample and the gas diffusion space in the device (including the diffusion chamber, the gas sampling system and the pipeline between them):

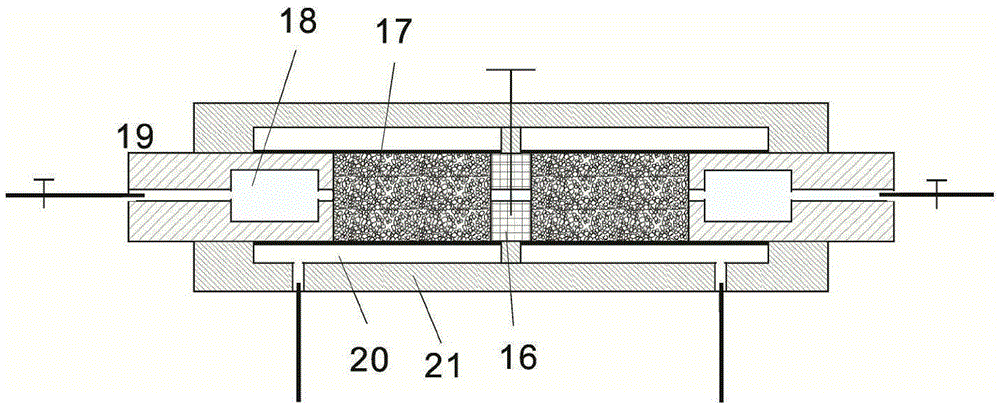

[0059] (A1) Select two pieces of length l and diameter d as 5cm and 2.54cm respectively (that is, the cross-sectional area s is 5.07cm 2 ), load the small cylindrical rock sample into holder 1 and assemble holder 1;

[0060] (A2) Select 10 gas sampling units, assemble them int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com