Cut tobacco production batch homogenization evaluation method

An evaluation method and homogenization technology, applied to measuring devices, instruments, scientific instruments, etc., to reduce the amount of data and improve the accuracy of process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

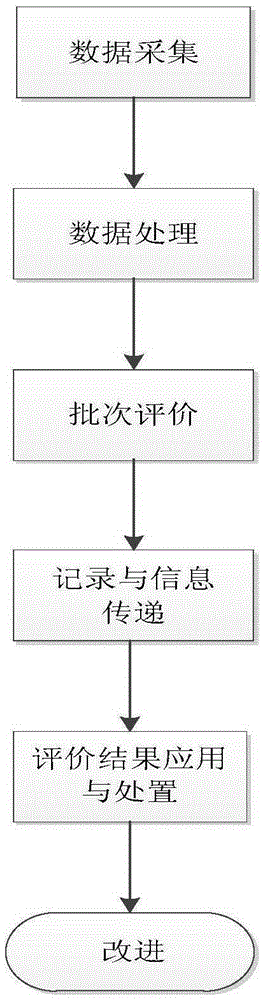

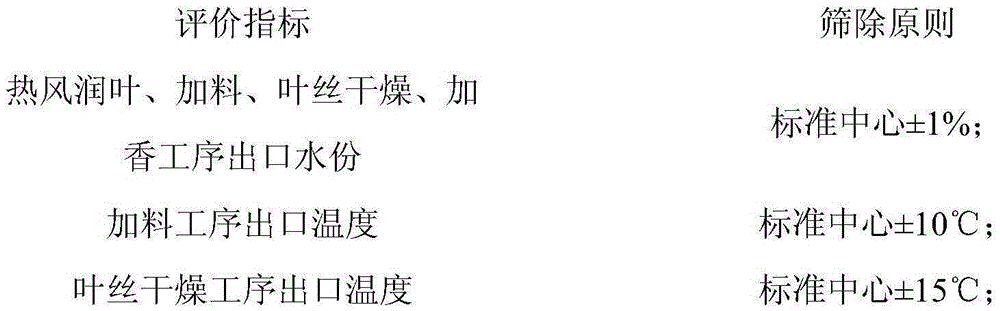

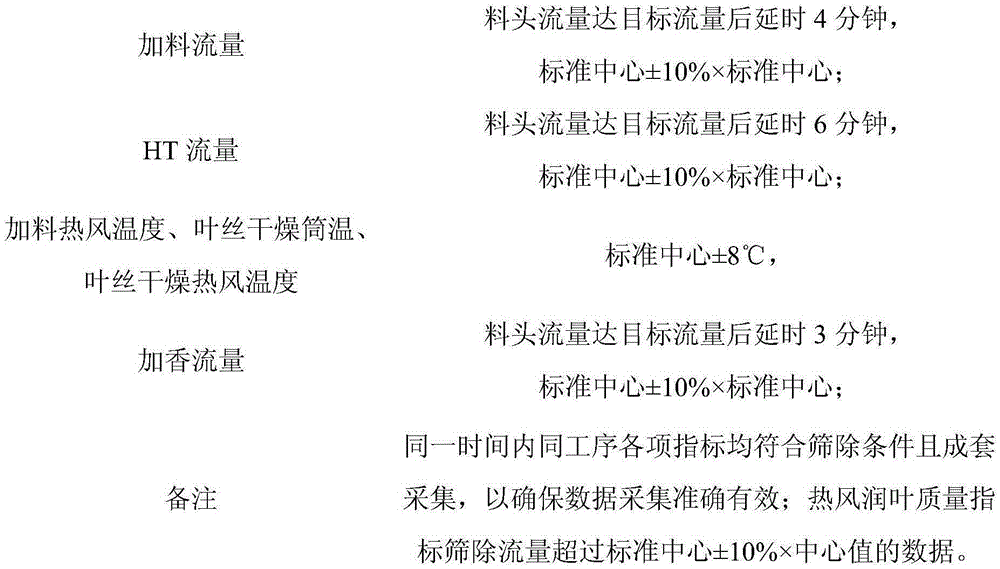

[0083] The data processing and evaluation method of the present invention is as follows: in order to ensure that process parameters and quality indicators are within the standard range, process abnormalities can be found in time, and online collection and test data are fully utilized to establish a "batch shredded tobacco quality evaluation standard". Each batch of shredded tobacco produced is evaluated, and the batch evaluation index consists of three parts: key quality index, key control parameter index and off-line technical and economic index. Different evaluation methods are adopted according to the importance of the index. The evaluation methods include standard compliance, offset, and fluctuation, that is, data processing methods such as index batch mean, mean deviation, and standard deviation. Among them, the quality index consists of the moisture content of the export material, the temperature of the export material, and the accuracy of feeding and flavoring. The moist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com