Synthesis method for preparing water-soluble biomass-based fluorescent carbon dot and application

A synthesis method and biomass technology, which are applied in the field of nanomaterials science and application, can solve the problems of harsh preparation conditions and expensive raw materials of fluorescent carbon dots, and achieve the effect of solving the harsh preparation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

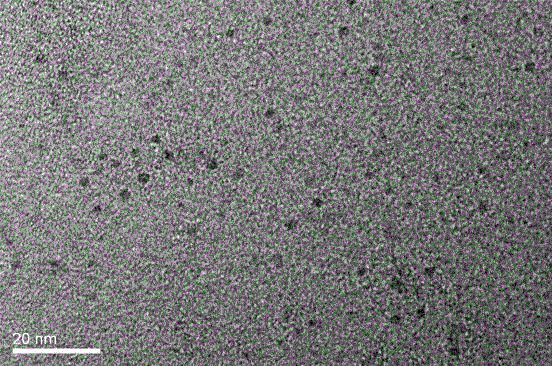

[0024] The preparation of embodiment 1 biomass-based fluorescent carbon dot material

[0025] Put 0.5g of cellulose powder and 0.35g of urea powder into a polytetrafluoroethylene reaction kettle, and simultaneously use 10ml of deionized water as a solvent. Put the reaction kettle in a constant temperature oven at 180°C, react for 72 hours, centrifuge to obtain a brown carbon dot reaction solution, dialyze the reaction solution with a 5-10kDa dialysis tube for 72 hours, and freeze-dry the dialyzed solution to finally obtain a biomass-based Fluorescent carbon dot material.

Embodiment 2

[0026] The preparation of embodiment 2 biomass-based fluorescent carbon dot materials

[0027] Put 0.5g of cellulose powder and 0.35g of urea powder into a polytetrafluoroethylene reaction kettle, and simultaneously use 10ml of deionized water as a solvent. Put the reaction kettle in a constant temperature oven at 200°C, react for 72 hours, centrifuge to obtain a brown carbon dot reaction solution, dialyze the reaction solution with a 5-10kDa dialysis tube for 72 hours, and freeze-dry the dialyzed solution to finally obtain biomass-based Fluorescent carbon dot material

Embodiment 3

[0028] The preparation of embodiment 3 biomass-based fluorescent carbon dot materials

[0029] Put 0.5g of cellulose powder and 0.35g of urea powder into a polytetrafluoroethylene reaction kettle, and simultaneously use 10ml of deionized water as a solvent. Put the reaction kettle in a constant temperature oven at 200°C, react for 72 hours, centrifuge to obtain a brown carbon dot reaction solution, dialyze the reaction solution with a 5-10kDa dialysis tube for 72 hours, and freeze-dry the dialyzed solution to finally obtain biomass-based Fluorescent carbon dot material.

[0030] The raw materials in this embodiment are commercially available analytically pure raw materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com