Judgment method for fatigue failure of titanium alloy at room temperature

A technology of load fatigue and fatigue failure, which is applied to measuring devices, material analysis through optical means, instruments, etc., can solve problems such as incorrect conclusions and difficulties in the strength of load fatigue failure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Determination of fatigue failure of Ti6242 alloy under load at room temperature

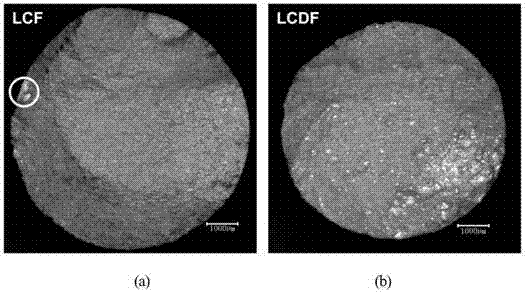

[0044] Ti6242 alloy adopts such as figure 2 The samples shown are in accordance with image 3 The two types of fatigue waveforms shown are loaded until fracture. The LCF and LCDF fatigue fractures of Ti6242 alloy were observed by optical microscope, such as Figure 4 shown. It can be judged according to the degree of lightness and darkness on the respective fractures that the crack initiation position of the LCF fracture is at the far right end of the figure, which is the initiation on the surface of the sample; observing the LCDF fracture, it can be found that there are many and scattered bright areas on the fracture, basically distributed in the sub-surface of the sample Surface or interior, presenting multi-point initiation.

[0045] The cleavage facets of the initiation region on the fracture surface of Ti6242 alloy LCF and LCDF were further enlarged and observed with a...

Embodiment 2

[0049] Example 2: Determination of fatigue failure of Ti6243 alloy under load at room temperature

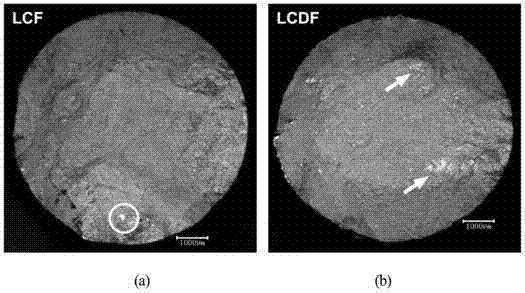

[0050] Ti6243 alloy adopts such as figure 2 The samples shown are in accordance with image 3 The two types of fatigue waveforms shown are loaded until fracture. The LCF and LCDF fatigue fractures of Ti6243 alloy were observed by optical microscope, such as Figure 9 shown. It can be judged according to the degree of light and darkness on the respective fractures that there are two crack initiation positions on the fracture of the LCF, respectively at the bottom end and the rightmost end of the figure, both of which are initiated on the surface of the sample; observing the fracture of the LCDF, it can be found that there is a bright area inside the sample on the fracture ( As indicated by the arrow), but it is significantly less than the LCDF fracture in Example 1. At the same time, at the far right end of the fracture, a region similar to the brightness of the LCF fracture...

Embodiment 3

[0054] Example 3: Determination of Fatigue Failure of Ti6244 Alloy at Room Temperature

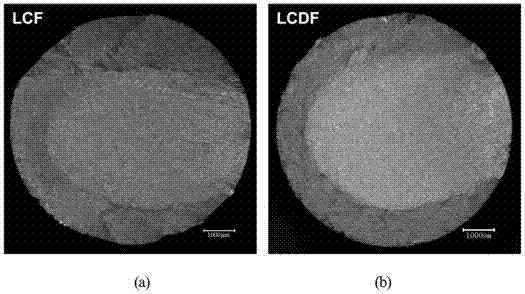

[0055] Ti6244 alloy adopts such as figure 2 The samples shown are in accordance with image 3 The two types of fatigue waveforms shown are loaded until fracture. Using an optical microscope to observe the LCF and LCDF fatigue fractures of Ti6244 alloy, such as Figure 11 shown. It can be judged according to the degree of lightness and darkness on the respective fractures that both the LCF and LCDF fractures are fatigue cracks initiated from the surface of the sample, and the initiation position is at the far right end of the fracture diagram.

[0056] Comparing the secondary cracks of Ti6244 alloy LCF and LCDF fracture longitudinal sections can be found, such as Figure 12 As shown, most of the secondary cracks in the longitudinal sections of LCF and LCDF are inclined and form an angle of about 45° with the stress axis.

[0057] This situation shows that the Ti6244 alloy does not hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com