SMD inductance device with magnetic rubber coating iron core and processing technology thereof

A technology of inductance device and adhesive coating, applied in the field of SMD inductance device and its processing technology, can solve the problems of easy error, increase enterprise cost, easy occurrence of defective products, etc., achieve good protection, prevent excessive instantaneous current, and good induction effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

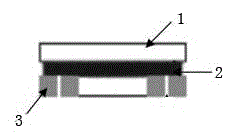

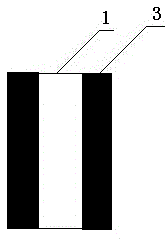

[0019] Depend on figure 1 , 2 It can be seen that a SMD inductance device with a magnetic glue coated iron core includes a substrate 1, one end of the substrate 1 is coated with a silver paste layer 3, and the concave parts of the substrate 1 and the silver paste layer 3 are wound with enamelled copper wires, enameled A protective layer 2 is plated on the copper wire, and the protective layer 2 is made of plastic BASE material. The base 1 is a ferrite iron core, the surface of the guide piece 3 is plated with silver, the base 1 is made of carbonyl iron powder material, the surface of the base 1 is plated with nickel and tin, and the length of the base 1 is 2.5+0.3 / -0.1mm, the width is 2.0+0.35 / -0.05mm, and the overall height of the device is less than or equal to 1.2mm.

[0020] The present invention comprises the following steps carried out in sequence:

[0021] 1) W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com