Method for manufacturing electrical steel sheet laminated core having reduced core loss and increased strength, and laminated core produced by the same

A technology of electrical steel sheets and laminated iron cores, applied in the field of laminated iron cores, can solve problems such as the limitation of firmly joining electrical steel sheets, achieve the effects of improving magnetic properties and preventing welding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

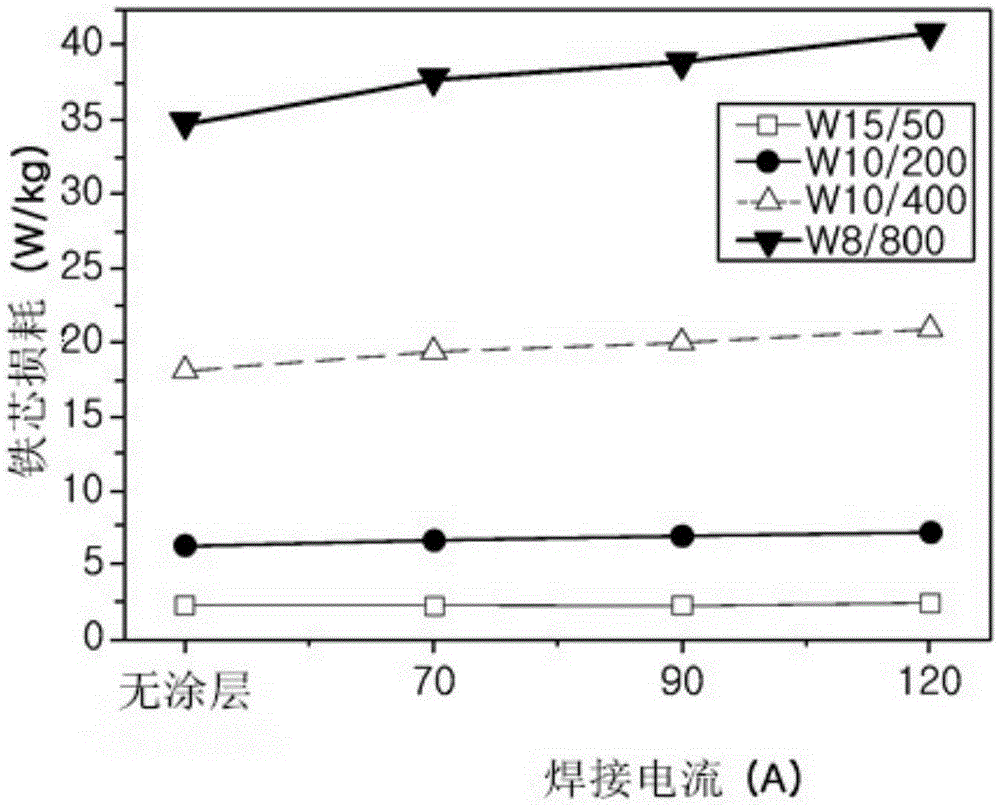

example 1

[0060] A 0.35 mm thick strip of electrical steel sheet coated with chromium-containing insulating material and having 3 wt% silicon (Si) was punched to form electrical steel sheets, which were stacked to form laminations for motor stators. When the laminated part is pressed by the pressing cylinder under the pressure of 2MPa, the laminated part is welded by the TIG method using welding wire as the welding material. With 7.8×10 -7 STS310 solid wire with a resistivity of Ωm, a relative magnetic permeability of 1.003, a melting point of 1450° C. and a diameter of 0.9 mm was used as the welding wire. The welding wire of the comparative sample utilizes a 1.8×10 -7 It is made of 50kgf grade carbon steel wire with resistivity of Ωm, relative permeability of 1000 and melting point of 1529°C. Since the magnetic properties of the laminated core depend on the lamination factor of the laminated core, the same number of electrical steel sheets are stacked in each lamination section. Fou...

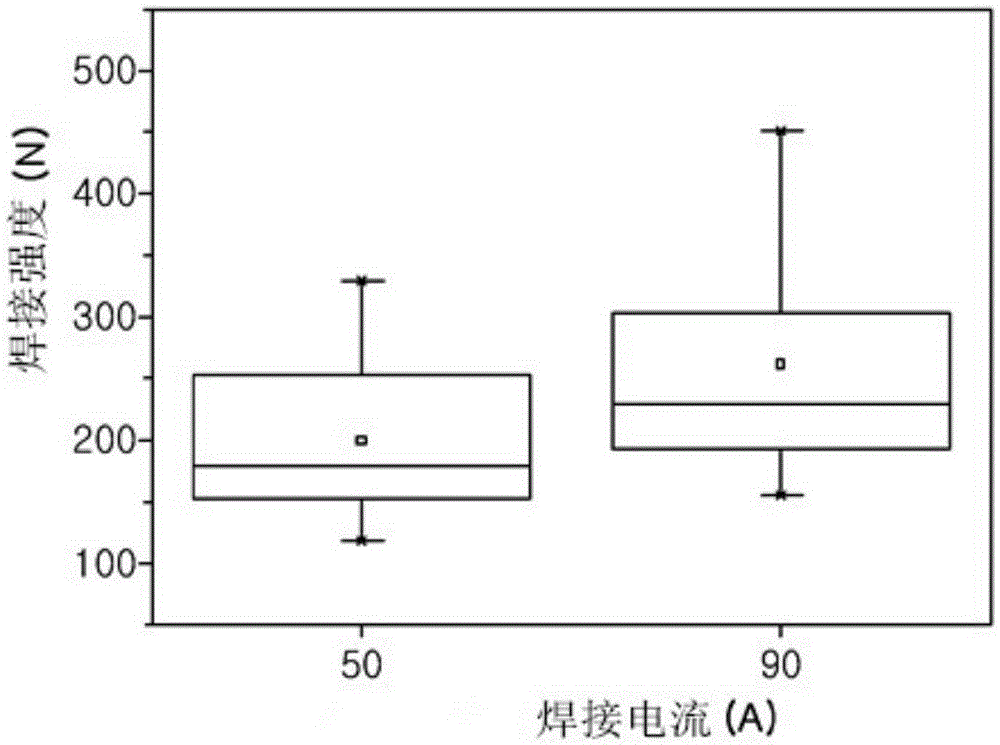

example 2

[0068] A 0.30 mm thick strip of electrical steel sheet coated with chrome-free insulating material and having 3 wt% silicon (Si) was punched to form electrical steel sheets, which were stacked to form laminations for motor stators. When the laminated part is pressed by the pressing cylinder under a pressure of 0.5 MPa, the laminated part is welded by the same TIG method as in Example 1 using welding wire as the welding material. With 7.8×10 -7 The resistivity of Ωm, the relative magnetic permeability of 1.003, the melting point of 1450°C and the STS310 solid wire with a diameter of 0.9mm and 7.2×10 -7 STS308L solid wire with a resistivity of Ωm, a relative magnetic permeability of 1.004, a melting point of 1419° C. and a diameter of 0.9 mm was used as the welding wire. The welding current was 50 A, the welding speed was 300 mm / min, the feeding speed of welding wire was 700 mm / min, and argon (Ar) as a shielding gas was supplied at a speed of 12.5 L / min. The laminated core man...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com