Punching device for seamless steel pipe and machining method using punching device

A technology for seamless steel pipes and equipment, applied in the field of automation equipment, can solve problems such as low processing efficiency and inability to guarantee processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

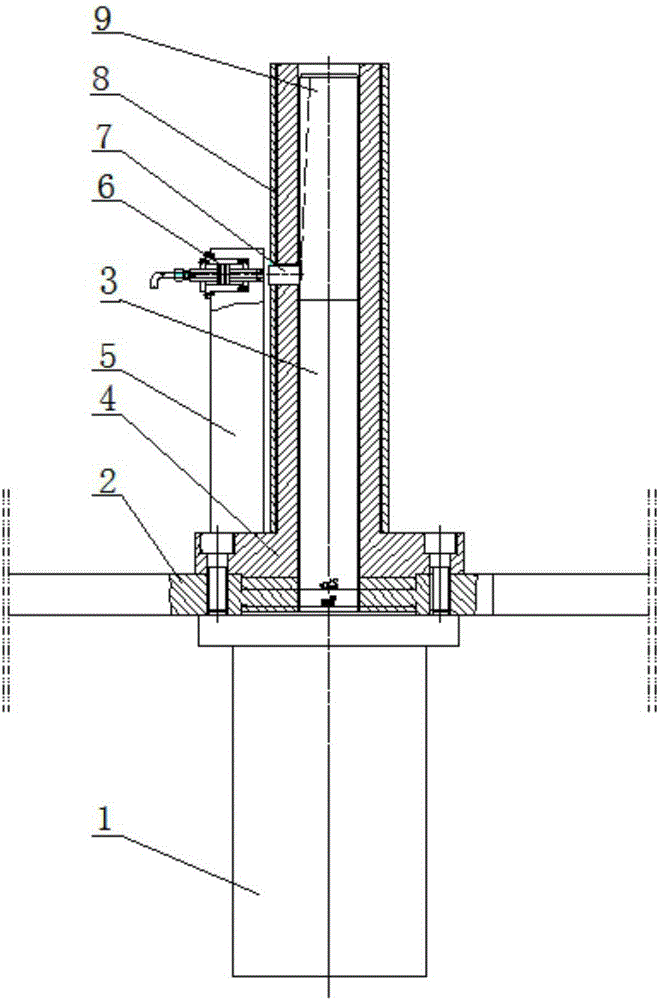

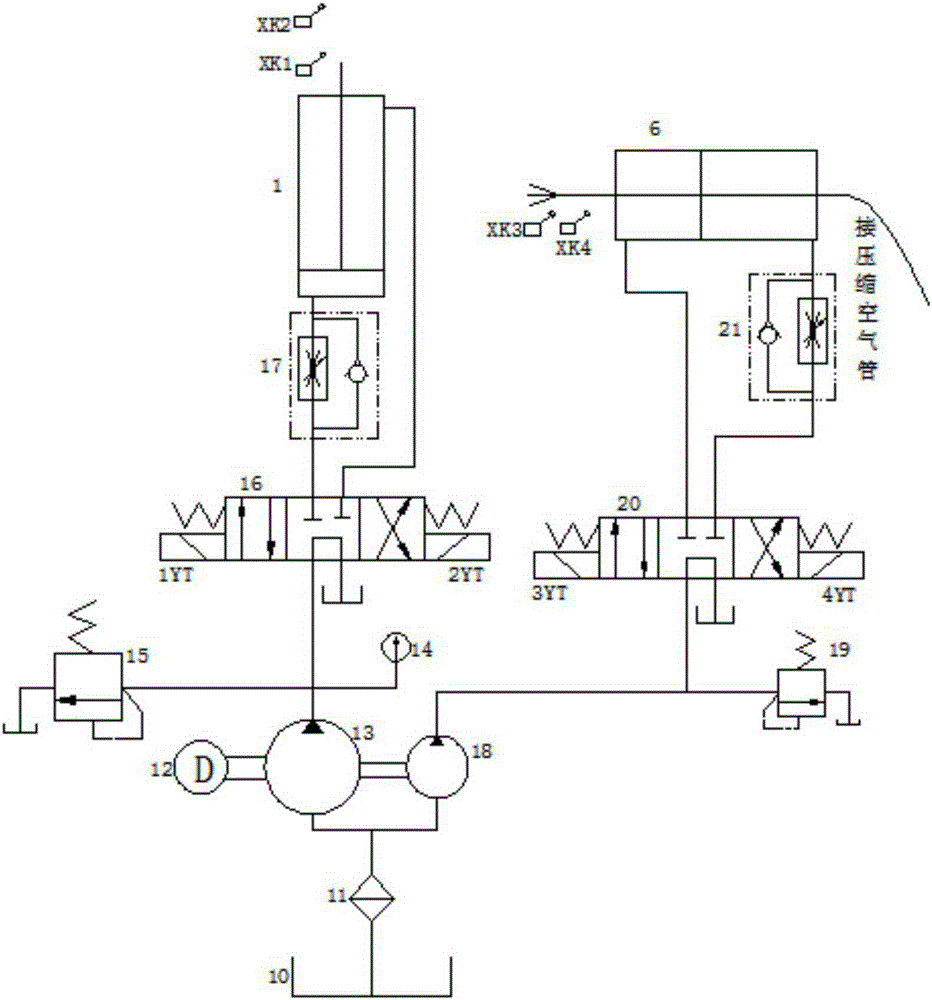

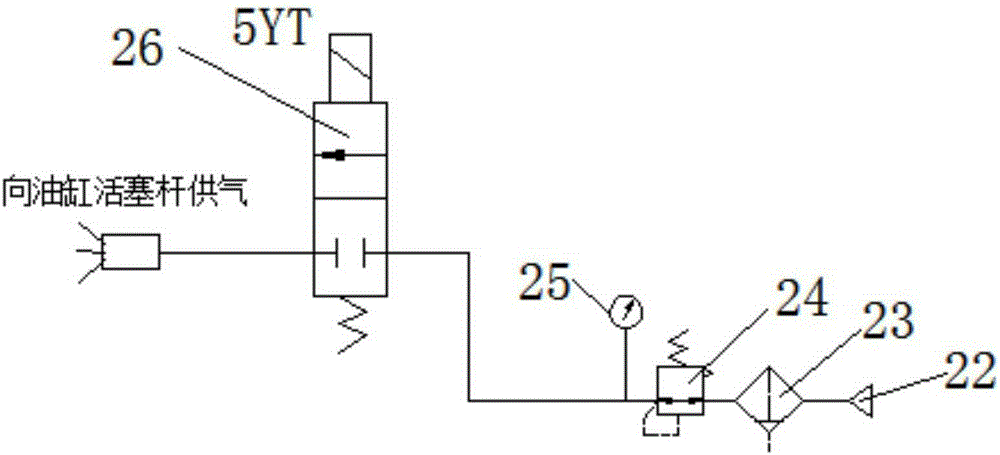

[0028] Such as Figure 1-Figure 3 As shown, the present invention provides a punching device for seamless steel pipes, including a device body, a hydraulic transmission system and an air injection mechanism.

[0029] The hydraulic transmission system includes a fuel tank 10, an oil filter 11, a main oil pump 13, a pressure gauge 14, a first overflow valve 15, a first electromagnetic reversing valve 16, a first one-way speed regulating valve 17, a main oil cylinder 1 and auxiliary hydraulic pressure system. The auxiliary hydraulic system includes an auxiliary oil pump 18 , a second overflow valve 19 , a second electromagnetic reversin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com