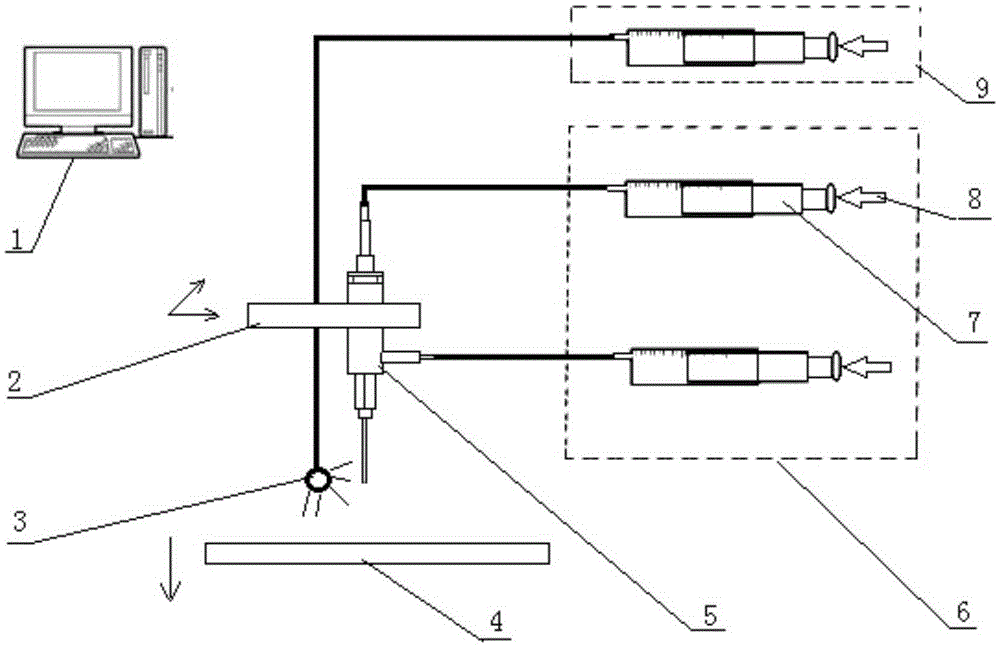

3D printing system and technology of coaxial sprayer and enhanced type hollow gel pipe of coaxial sprayer

A coaxial nozzle and 3D printing technology, applied in the field of 3D printing system, can solve the problems of difficult to meet the requirements of biological manufacturing, difficult to ensure the coaxiality of the inner and outer tubes, poor mechanical strength of the hollow circular tube, etc., to achieve simple structure and high performance. Reliable, uniform wall thickness results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

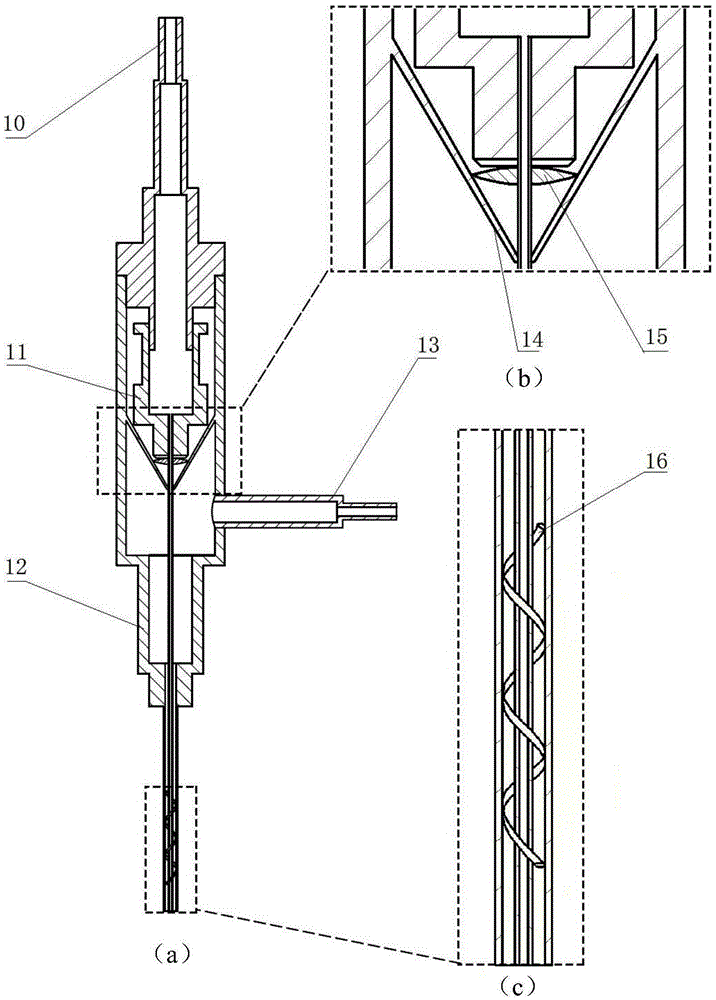

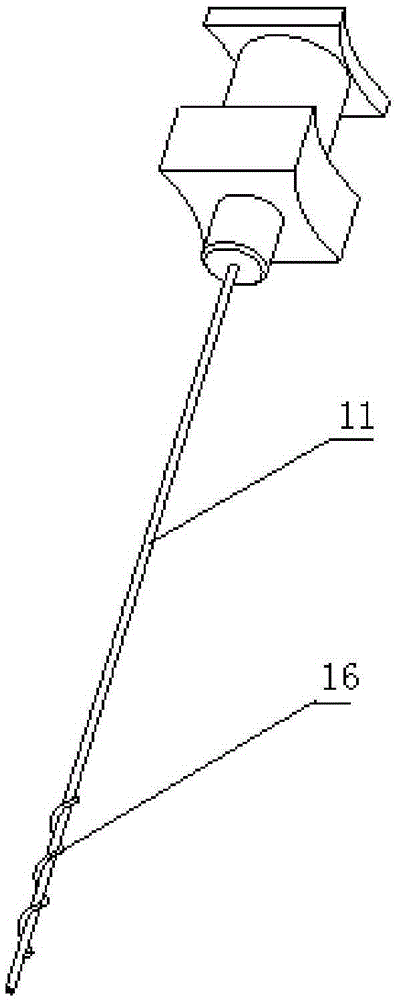

Method used

Image

Examples

Embodiment 1

[0047] Select inner tube inner diameter 0.34mm, outer diameter 0.63mm; outer tube inner diameter 1.12mm, outer diameter 1.48mm coaxial nozzle, sodium alginate solution concentration is 2%-4% (w / v), calcium chloride solution concentration is 4% (w / v), the concentration of ferric chloride solution is 0.25% (w / v). The extrusion rate of the sodium alginate solution is 1.5ml / min, that of the calcium chloride solution is 1-3ml / min, and that of the ferric chloride is 4.5ml / min. Reinforced hollow gel tubes with an outer diameter of 800-1200 μm can be printed.

Embodiment 2

[0049] Select inner tube inner diameter 0.24mm, outer diameter 0.45mm; outer tube inner diameter 0.70mm, outer diameter 1.06mm coaxial nozzle, the concentration of sodium alginate solution is 2%-4% (w / v), calcium chloride solution The concentration was 4% (w / v), and the concentration of the ferric chloride solution was 0.25% (w / v). The extrusion rate of the sodium alginate solution is 1.5ml / min, that of the calcium chloride solution is 1-3ml / min, and that of the ferric chloride is 4.5ml / min. Reinforced hollow gel tubes with an outer diameter of 500-800 μm can be printed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com