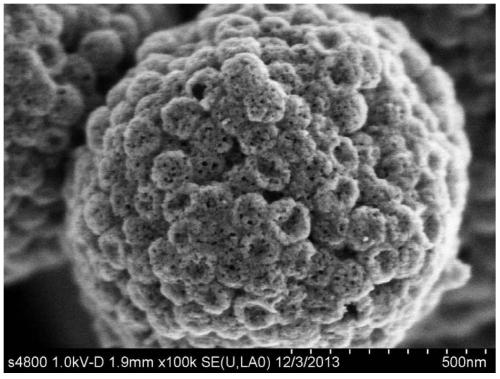

A kind of heteroatom-doped carbon microsphere and preparation method thereof

A technology of carbon microspheres and heteroatoms, applied in the field of heteroatom-doped carbon microspheres and its preparation, can solve the problems of difficulty in preparing heteroatom-doped carbon materials, complicated preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

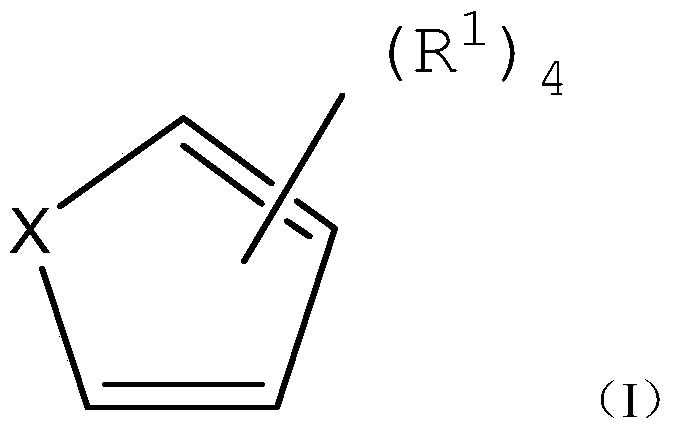

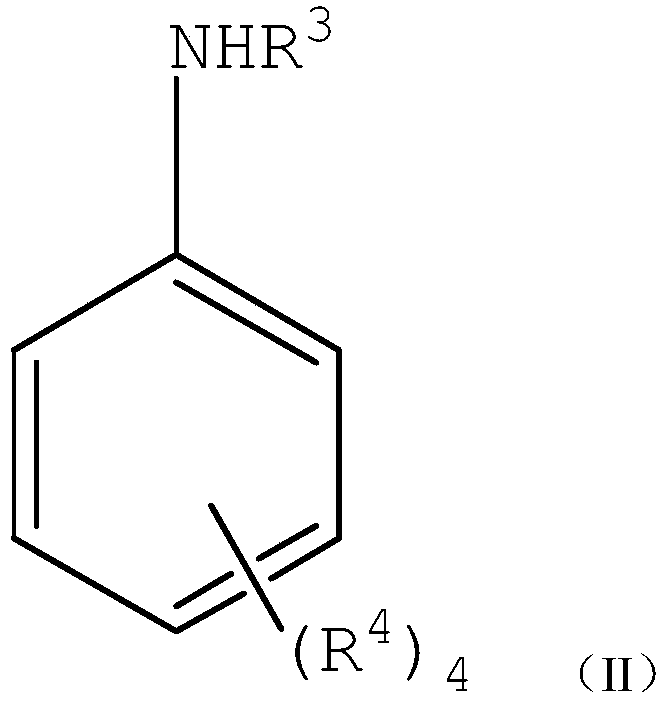

Method used

Image

Examples

Embodiment 1

[0058] Step 1) Preparation of styrene-acrylic-polypyrrole core-shell emulsion: take a certain amount of styrene-acrylic emulsion (BC-991, Beijing Dongfang Yakeli Chemical Technology Co., Ltd.), and add it to a reaction vessel equipped with a mechanical stirring device, and then Add the pyrrole monomer whose quality is 10% of styrene-acrylic resin and start to swell the styrene-acrylic latex particles. After swelling for 1 hour, add polyvinylpyrrolidone (K30, molecular weight is about 10,000, Xilong Chemical Co., Ltd.), p-toluenesulfonic acid and ferric chloride hexahydrate (III) aqueous solution, after the system is placed in an ice-water cooling bath for cooling, 30% hydrogen peroxide aqueous solution is added to start the reaction, the solid content of the system is 5%, and in the final system, polyvinylpyrrolidone, The concentrations of p-toluenesulfonic acid, iron(III) chloride hexahydrate and hydrogen peroxide were 60mM, 40mM, 0.1mM and 120mM respectively, and the reaction...

Embodiment 2

[0062] Step 1) The preparation of the styrene-acrylic-polypyrrole core-shell emulsion is the same as in Example 1.

[0063] Step 2) The drying of the styrene-acrylic-polypyrrole emulsion is also the same as in Example 1.

[0064] Step 3) The high-temperature carbonization of the product is carried out under nitrogen atmosphere, and the carbonization temperature is 700°C. The data of the BET specific surface area, pore diameter, pore volume and nitrogen content of the product are shown in Table 1.

Embodiment 3

[0066] Step 1) The preparation of the styrene-acrylic-polypyrrole core-shell emulsion is the same as in Example 1.

[0067] Step 2) The drying of the styrene-acrylic-polypyrrole emulsion is also the same as in Example 1.

[0068] Step 3) The high-temperature carbonization of the product is carried out under nitrogen atmosphere, and the carbonization temperature is 600°C. The data of the BET specific surface area, pore diameter, pore volume and nitrogen content of the product are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com