High-Salinity Wastewater Treatment Process with Highly Efficient Combined Steam Source

A combined steam and wastewater treatment technology, which is applied in the field of wastewater treatment, can solve problems such as environmental pollution, power generation fluctuations, and energy structure deterioration, and achieve the effects of avoiding environmental pollution, avoiding electricity storage, and avoiding low heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

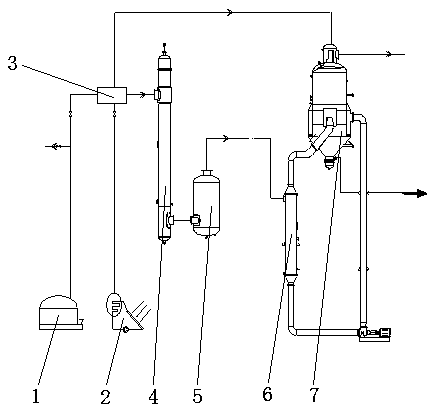

Image

Examples

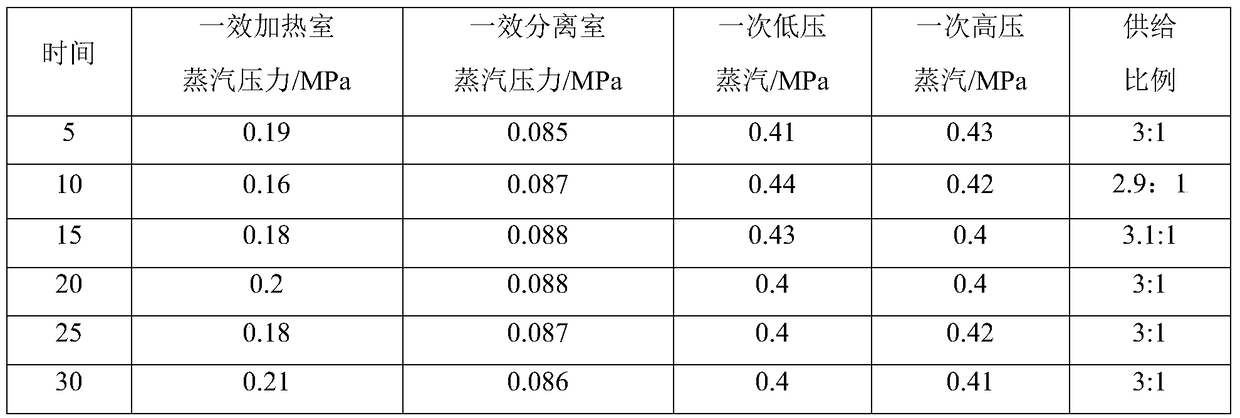

Embodiment 1

[0041] In the high-salt wastewater treatment process with a high-efficiency combined steam source in this embodiment, the salt concentration of the high-salt wastewater is 30-40%.

[0042]In the evaporation crystallization process, the heating temperature of the first-effect heating chamber in the first-effect evaporation crystallizer is 115-125°C, and the temperature of the first-effect separation chamber is 95-105°C. The heating temperature of the second-effect heating chamber in the two-effect evaporation crystallizer is 95-105°C, and the temperature of the second-effect separation chamber is 70-80°C.

[0043] The working steps of the steam conditioning equipment of the present embodiment are as follows:

[0044] A) Set the vapor pressures required in the first-effect evaporative crystallizer and the second-effect evaporative crystallizer respectively.

[0045] The steam pressure required by the first-effect heating chamber is 0.2MPa, and the steam pressure required by the...

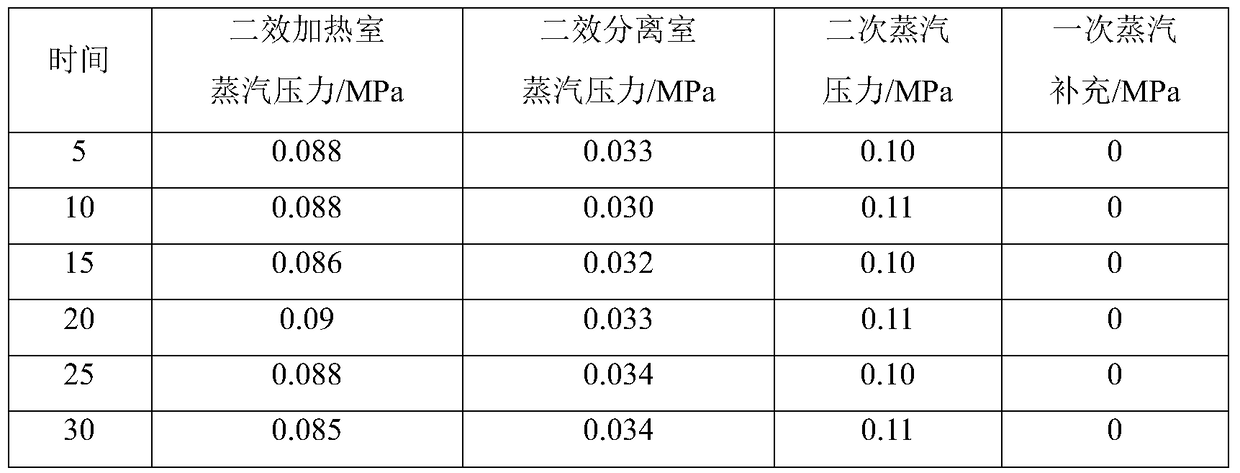

Embodiment 2

[0054] In the high-salt wastewater treatment process with a high-efficiency combined steam source in this embodiment, the salt concentration of the high-salt wastewater treatment is 25-30%.

[0055] In the evaporation crystallization process, the first-effect evaporation crystallizer is composed of a first-effect heating chamber and a first-effect separation chamber. The heating temperature of the first-effect heating chamber is 105-115°C, and the temperature of the first-effect separation chamber is 90-98°C. The second-effect evaporation crystallizer is composed of a second-effect heating chamber and a second-effect separation chamber. The heating temperature of the second-effect heating chamber is 90-98°C, and the temperature of the second-effect separation chamber is 70-75°C.

[0056] The working steps of the steam conditioning equipment of the present embodiment are as follows:

[0057] A) Set the vapor pressures required in the first-effect evaporative crystallizer and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com