Methods for maximum nitrite accumulation during denitrification

A nitrite and denitrification technology, applied in the direction of anaerobic digestion treatment, etc., can solve the problems of easy damage, long start-up time, complicated control process, etc., and achieve high nitrite accumulation, short start-up time, and nitrite The effect of high accumulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Combined with specific experimental examples, this method is further explained:

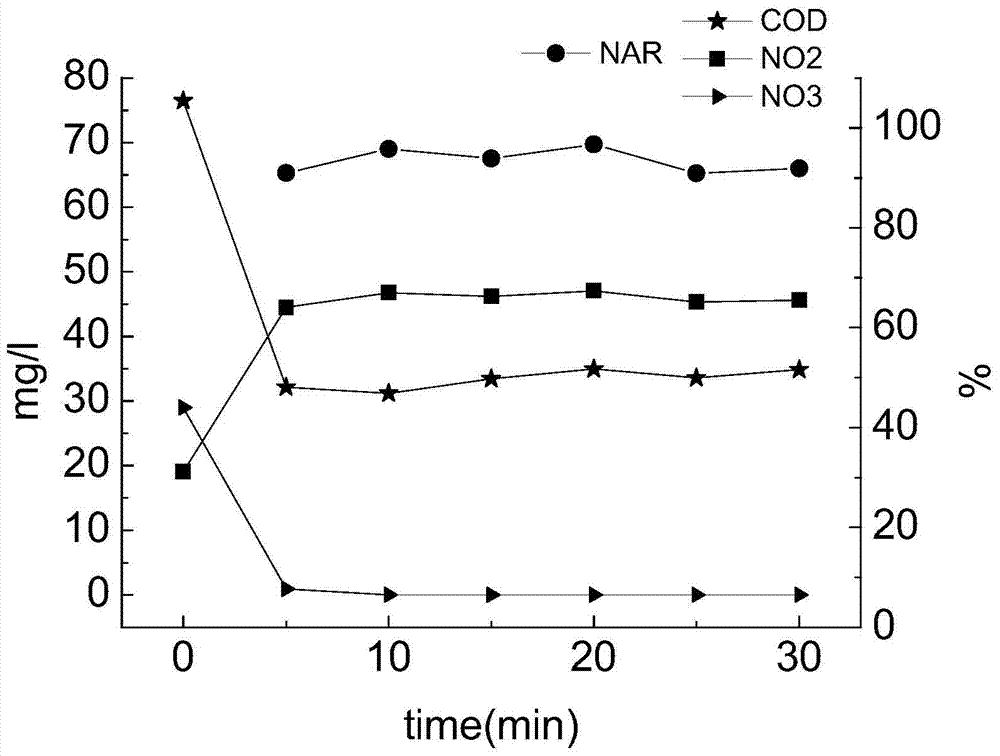

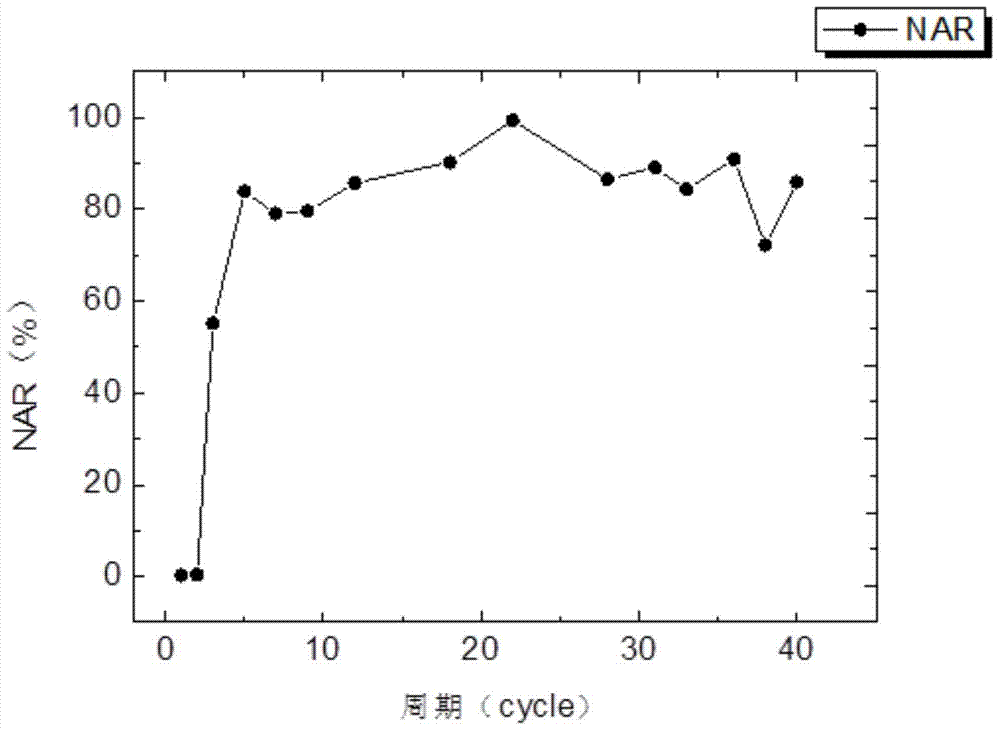

[0026] The SBR reactor was used to carry out the experiment of nitrite accumulation in the process of denitrification. The effective volume of the reactor was 10L; each cycle of the SBR reactor included water intake for 6 minutes, anoxic stirring for 35 minutes, precipitation for 20 minutes, and then the supernatant was discharged. 50%.

[0027] Specifically include the following steps:

[0028] (1) Inoculate the sludge in the primary sedimentation tank, and control the concentration of the influent sludge at 2000-4000mg / L.

[0029] (2) After the nitrate wastewater enters the denitrification reactor, adjust the pH value in the reactor to 9-9.5, and then add sodium acetate to make the system's initial COD / NO 3 - -N is between 2.5 and 3.5;

[0030] (3) Anoxic stirring, the specific time is set as follows: in the first cycle, measure the NO in the reactor every hour after the stirring sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com