A sludge filter press and sludge treatment method

A sludge filter press and sludge treatment technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of limited compression spring compression stroke and sludge squeeze Limited pressing effect, affecting the effect of filter pressing, etc., to achieve the effect of high pressing pressure, high production efficiency, and convenient transportation and landfill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

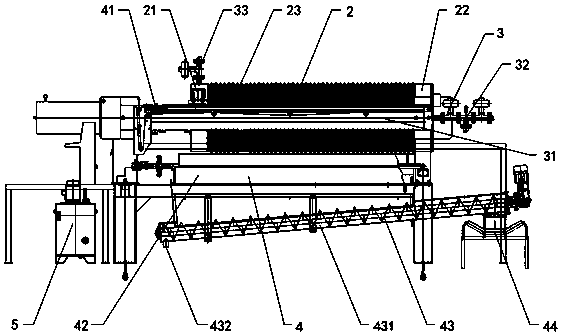

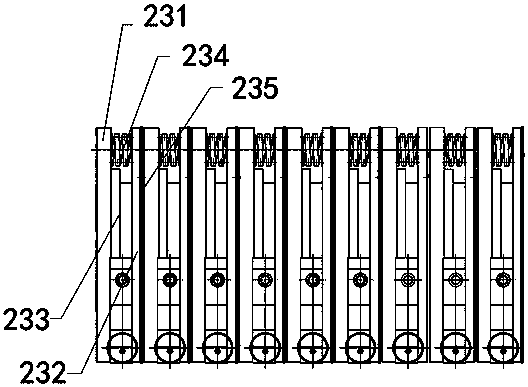

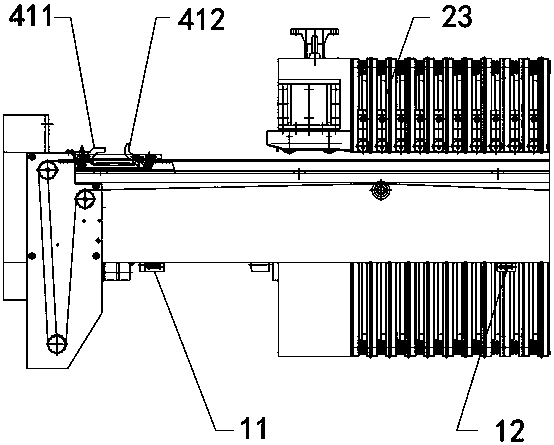

[0037] according to Figure 1 to Figure 5 Shown, a kind of sludge filter press comprises, frame, filter press part 2, feeding part 3, discharge part 4 and electric control part 5, wherein, filter press part 2 comprises, slides on frame The push plate 21 of the compression action and the thrust plate 22 fixed on the frame to cooperate with the push plate 21 to compress and several filter plate units 23 connected in series between the push plate 21 and the thrust plate 22; the filter plate unit 23 Including, a metal back plate 231, a piston plate 232, a pressure ring 233 and a spring 234 arranged between the back plate 231 and the piston plate 232; several filter cavities 235 are formed between the filter plate units 23, and the filter cavities 235 are formed on the push plate 21 Under the action of pressure and the elastic force of the spring 234, it has the function of changing the size of the cavity.

[0038] Under the control of the electronic control unit 5, the feeding un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com