Foam concrete foaming agent and application thereof

A technology of foam concrete and foaming agent, which is applied in the field of building material manufacturing, can solve the problems of unsatisfactory foam concrete production and manufacturing process and unstable performance of foaming agent, etc., achieve strong foaming ability, good foam stability, and improve product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The raw material consumption of the foamed concrete blowing agent of the present embodiment is as follows:

[0040] Sodium dodecyl benzene sulfonate

25 grams;

20 grams;

Triterpene saponin air-entraining agent

20 grams;

Aluminum powder

30 grams;

2.5 grams;

0.5 grams;

EVA emulsion

2.0 grams.

[0041] Its application method is as follows:

[0042] Step 1, calculate the amount of each raw material according to the ratio of raw materials;

[0043] Step 2. Mix sodium dodecylbenzenesulfonate, sodium dodecylsulfate and triterpene saponins evenly according to the formula ratio, and dissolve them in water with a mass ratio of 1:25 to 30 by stirring to form the initial foaming agent solution;

[0044] Step 3, evenly disperse the foam stabilizer into the foaming agent solution while stirring, and stir at a high speed to form a foam ...

Embodiment 2

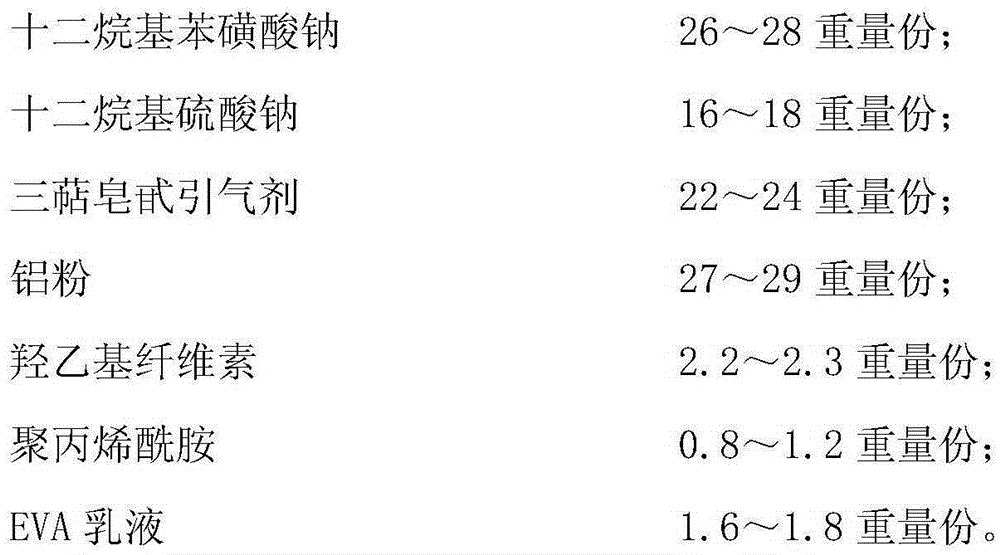

[0050] The raw material consumption of the foamed concrete blowing agent of the present embodiment is as follows:

[0051] Sodium dodecyl benzene sulfonate

[0052] Its application method is identical with embodiment 1.

Embodiment 3

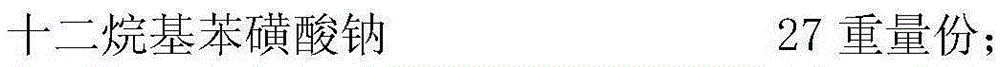

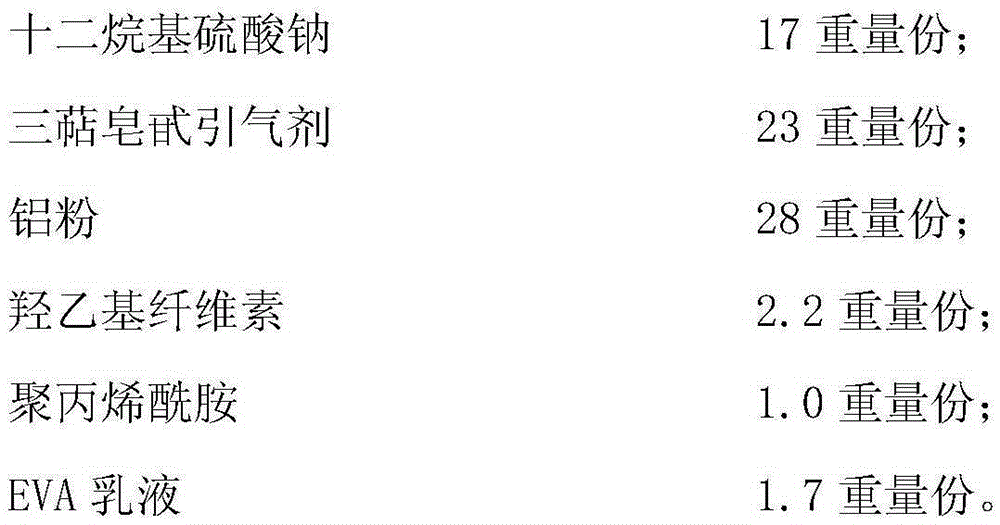

[0054] The raw material consumption of the foamed concrete blowing agent of the present embodiment is as follows:

[0055] Sodium dodecyl benzene sulfonate

[0056] Its application method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com