Microporous rare earth cluster metal organic anion framework and preparation method and application thereof

An anion framework and metal-organic technology, applied in the field of metal-organic anion framework and its preparation, can solve the problems of complex dye wastewater treatment, etc., and achieve the effect of simple preparation method and great application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Rare earth cluster metal organic anion framework of embodiment 1 microporous

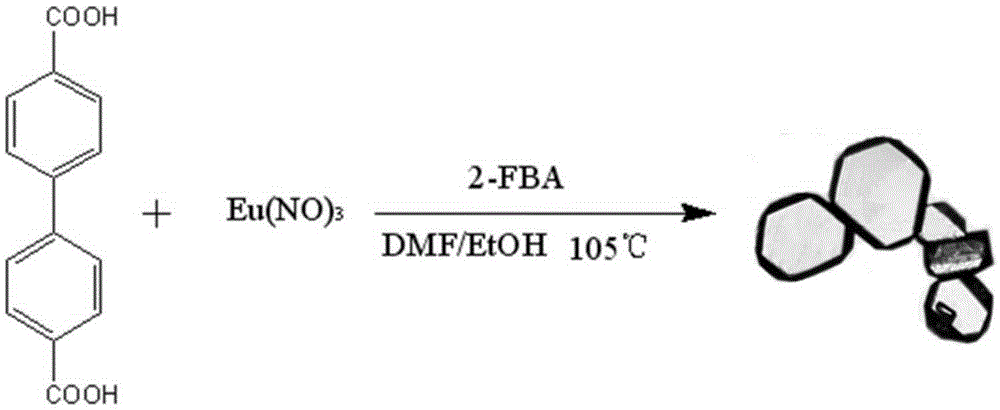

[0021] 0.0225mmol of Eu(NO 3 ) 3 , 0.0225mmol of 4,4'-biphenyldicarboxylic acid, 0.0675mmol of o-fluorobenzoic acid, 2ml of N,N-dimethylformamide (DMF), 0.5ml of ethanol were added to a glass bottle with a volume of 5ml, At room temperature, stir for 30 minutes. Seal the glass bottle and place in the oven. Heat to make the temperature of the oven rise from room temperature to 378K, and the heating rate is 5°C·min -1 , kept at this temperature for 36 hours. at 5℃·h -1 Slowly cool down to room temperature at a cooling rate of 0.5 to obtain light yellow cubic crystals; wash with N,N'-dimethylformamide (DMF) solution, filter and dry in the air, which is the target product microporous rare earth cluster metal organic Anionic framework with a yield of 68%.

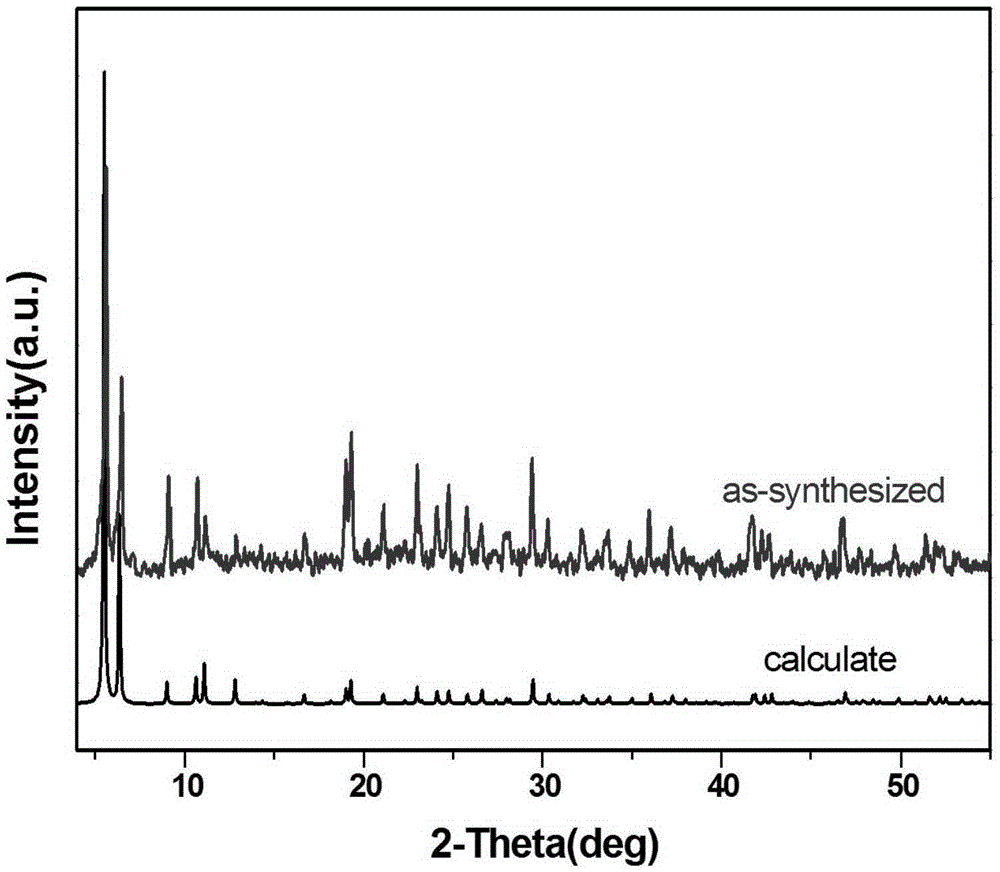

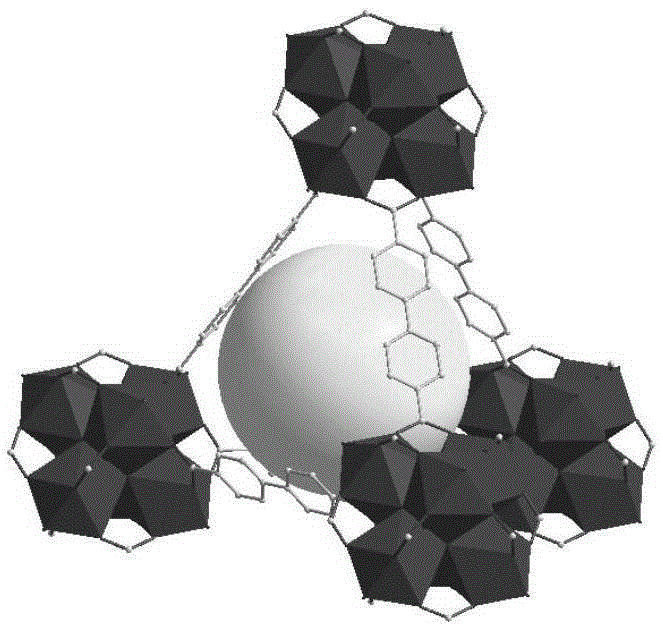

[0022] The structure of the microporous rare earth cluster metal organic anion skeleton synthesized by the present invention is as foll...

Embodiment 2

[0023] Example 2 A Microporous Rare Earth Cluster Metal Organic Anion Framework Selectively Adsorbs Organic Dyes

[0024] Method: The microporous rare-earth cluster metal-organic anion framework prepared in Example 1 was used as an adsorption matrix to adsorb mixed organic dyes.

[0025] 1) Dissolve the organic anionic dye methyl orange and the organic cationic dye methylene blue in a DMF solution to obtain methyl orange and methylene blue concentrations of 5×10 -5 Mixed dye solution of M.

[0026] Take 5ml of the mixed dye solution, add 20mg of microporous rare earth cluster metal organic anion framework crystals, and soak at room temperature. The change of dye concentration in the mixed dye solution was detected by UV-vis spectroscopy. The result is as Figure 5 As shown, the peaks in the figure from top to bottom are 0min, 10min, 30min, 1h, 2h, 3h, 4h, 6h, 24h. Depend on Figure 5 It can be seen that the characteristic peak intensity of methylene blue at 650nm in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com