Integrated gas-water separator protector

An integrated, protector technology, applied in the direction of gas production bioreactor, biological sludge treatment, waste fuel, etc., can solve the problems of freezing in low temperature environment, large footprint, complicated management, etc., and achieve uniform gas distribution , reduce maintenance costs, and ensure normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

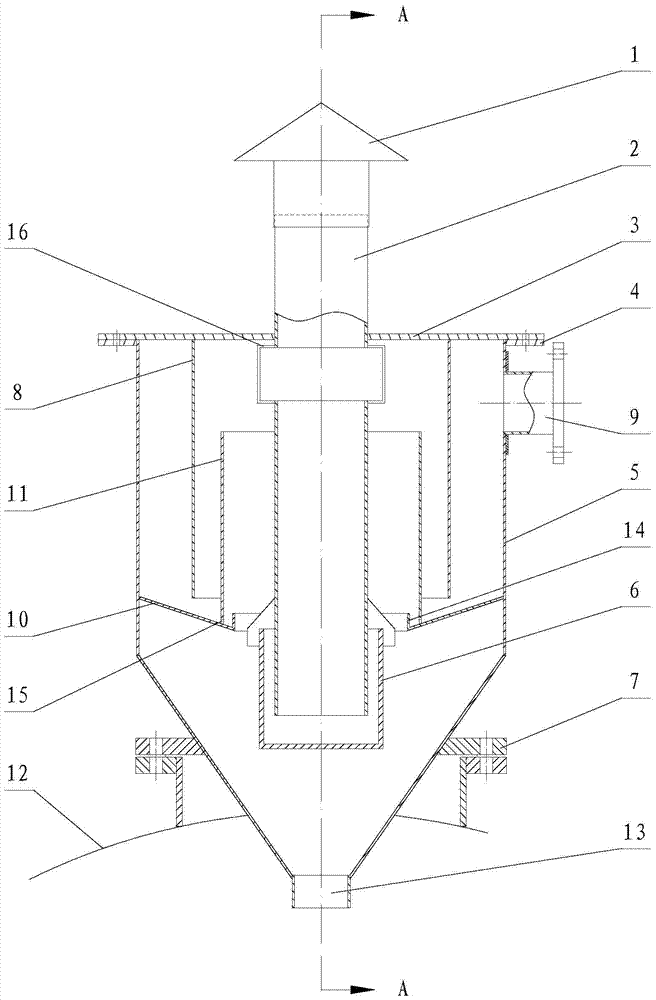

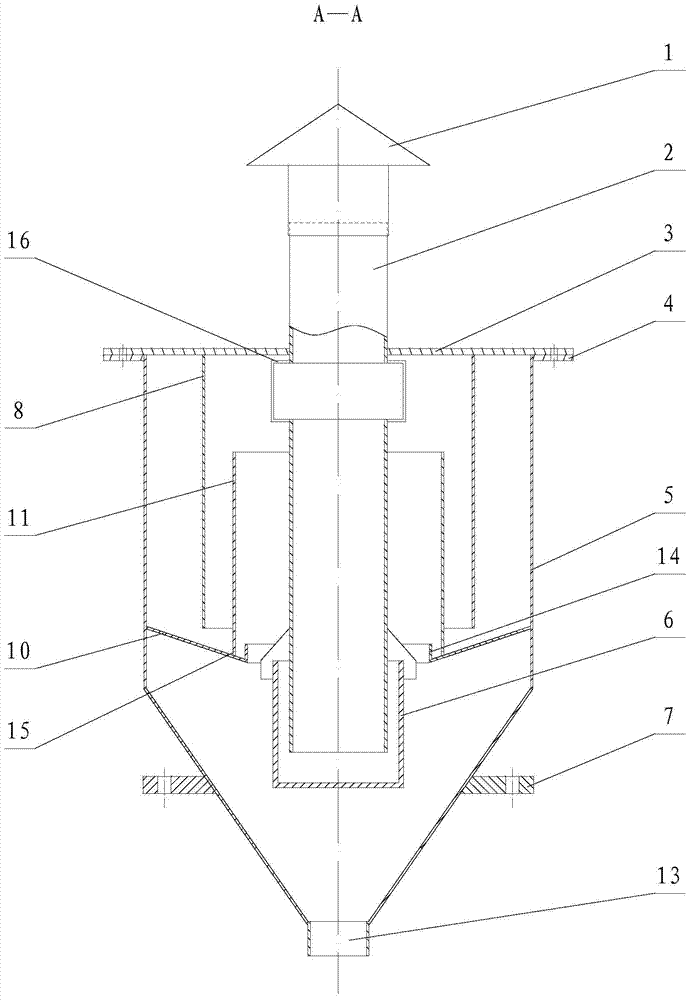

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] Such as figure 1 , figure 2 Shown, the present invention comprises rainproof cover 1, exhaust pipe 2, cover plate 3, cylinder body 5, water seal tank 6 and condensation bottom plate 10, wherein the top of cylinder body 5 is cylinder, and the bottom is cone, and in The outer surface of the cone is fixedly connected with the connecting flange 7 connected with the anaerobic fermentation tank 12 . The top of the cylinder 5 is fixedly connected with the cylinder flange 4 for connection, and the bottom end is provided with an air inlet 13 inserted into the anaerobic fermentation tank 12 and communicated with the anaerobic fermentation tank 12. The generated biogas with water vapor enters the cylinder body 5 through the air inlet 13 .

[0019] The cover plate 3 is circular, and the exhaust pipe 2 is fixedly connected in the middle. The cover plate 3 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com