A Cryogenic Magnetic Field Treatment Method for Improving Plastic Workability of Magnesium Alloys

A magnetic field treatment and plastic working technology is applied in the field of cryogenic magnetic field treatment to improve the plastic workability of magnesium alloys, and can solve the problems of limited application scope, low strain hardening index, poor room temperature plasticity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

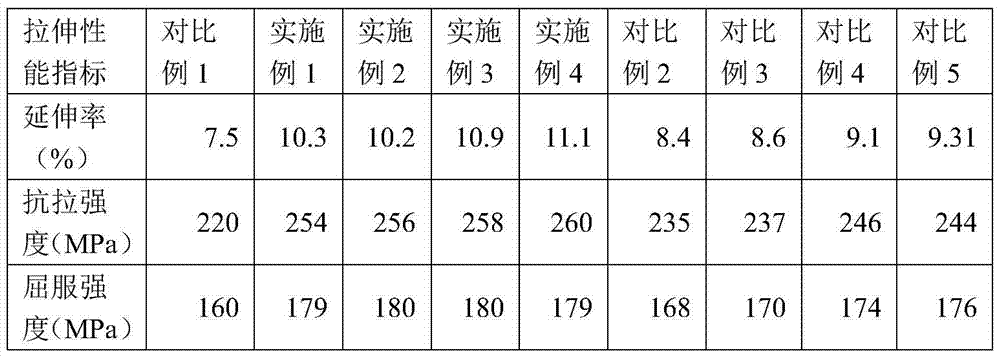

[0016] Choose AZ31 magnesium alloy (Al 3.19%, Zn0.81%, Mn0.334%, surplus is Mg) sheet material is cut into the standard sheet-like tensile sample of 45mm by wire cutting, adopts the effect of the present invention for comparative explanation, to this The standard sheet-shaped tensile sample was tested for tensile properties without any treatment. As comparative example 1, the results were as follows: elongation 7.5%, tensile strength 220Mpa, yield strength 160MPa; the rest of the samples were stretched Before the test, cryogenic magnetic field and tempering treatment were carried out by the method of the present invention. The treatment process and the parameters adopted are as follows.

[0017] First, the magnesium alloy sample is cooled to -145°C with liquid nitrogen according to the set cooling rate, that is, the cooling rate is 10°C / min in the process of dropping from room temperature to -100°C, and cooling from -100°C to -140°C The cooling rate in the process is 5°C / min, ...

Embodiment 2

[0020] Choose AZ31 magnesium alloy (Al 3.19%, Zn0.81%, Mn0.334%, surplus is Mg) sheet material is cut into the standard sheet-like tensile sample of 45mm by wire cutting, adopts the effect of the present invention for comparative explanation, to this The standard sheet-shaped tensile sample was tested for tensile properties without any treatment. As comparative example 1, the results were as follows: elongation 7.5%, tensile strength 220Mpa, yield strength 160MPa; the rest of the samples were stretched Before the test, cryogenic magnetic field and tempering treatment were carried out by the method of the present invention. The treatment process and the parameters adopted are as follows.

[0021] First, the magnesium alloy sample is cooled to -160°C with liquid nitrogen according to the set cooling rate, that is, the cooling rate is 10°C / min in the process of dropping from room temperature to -100°C, and cooling from -100°C to -140°C The cooling rate in the process is 5°C / min, ...

Embodiment 3

[0024] Choose AZ31 magnesium alloy (Al 3.19%, Zn0.81%, Mn0.334%, surplus is Mg) sheet material is cut into the standard sheet-like tensile sample of 45mm by wire cutting, adopts the effect of the present invention for comparative explanation, to this The standard sheet-shaped tensile sample was tested for tensile properties without any treatment. As comparative example 1, the results were as follows: elongation 7.5%, tensile strength 220Mpa, yield strength 160MPa; the rest of the samples were stretched Before the test, cryogenic magnetic field and tempering treatment were carried out by the method of the present invention. The treatment process and parameters adopted are as follows.

[0025] First, the magnesium alloy sample is cooled to -190°C with liquid nitrogen according to the set cooling rate, that is, the cooling rate is 10°C / min in the process of dropping from room temperature to -100°C, and cooling from -100°C to -140°C The cooling rate in the process is 5°C / min, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com