High-elasticity composite floor

A composite flooring and high-elasticity technology, which is applied in the direction of elastic flooring, construction, building construction, etc., can solve the problems of not widely used and expensive, etc., and achieve strong elastic recovery, improved elasticity and strong resistance, overlapping and transportation Fast and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

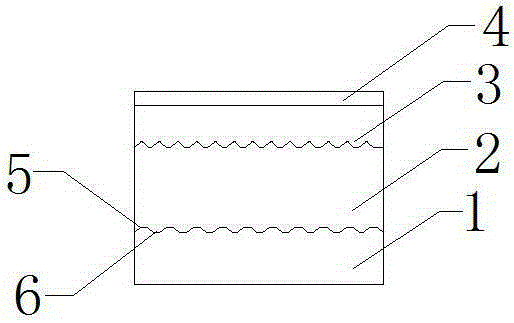

[0025] like figure 1 As shown, a highly elastic composite floor includes a base layer 1, a buffer layer 2 is arranged above the base layer 1, a connection layer 3 is arranged above the buffer layer 2, and a panel is arranged above the connection layer 3 Layer 4, one side of the base layer 1 is a plane, the other side is provided with a number of evenly distributed flanges 5, one side of the buffer layer 2 is serrated, and the other side is drilled with a number of evenly distributed grooves 6, buffering. The layer 2 is matched and overlapped with the flange 5 on the base layer 1 through the groove 6. One side of the connecting layer 3 is bonded to the panel layer 4, and the other side is zigzag, and is connected with the buffer layer. The zigzag shape on one side of the layer 2 is matched and overlapped; the thickness of the panel layer 4 is 0.12-0.2mm (the optimal thickness is 0.15mm, of course, 0.12mm or 0.2mm can also be selected), and the thickness of the connecting layer ...

Embodiment 2

[0035] This embodiment is the same as the first embodiment, the difference is that the buffer layer is made of a special PVC material, and the special PVC material is made of the following raw materials by weight: 5 parts of chlorinated polyethylene, 6 parts of nano silica gel parts, 84 parts of polyvinyl chloride resin, 12 parts of light calcium carbonate, 9 parts of calcium stearate, 5 parts of diallyl phthalate, 3 parts of MBS resin, 4 parts of silicon nitride nanoparticles, 7 parts of boron fiber parts, 2 parts of mildew inhibitor, 2 parts of heat stabilizer, 7 parts of plasticizer, the preparation process of the PVC material includes the following steps:

[0036] Step 1. Combine chlorinated polyethylene, nano silica gel, polyvinyl chloride resin, light calcium carbonate, calcium stearate, silicon nitride nanoparticles, MBS resin, boron fiber, mildew inhibitor, heat stabilizer, plasticizer Mix and stir evenly in the mixer according to a certain proportion, the stirring spe...

Embodiment 3

[0044] This embodiment is the same as the first embodiment, the difference is that the buffer layer is made of a special PVC material, and the special PVC material is made of the following raw materials by weight: 3 parts of chlorinated polyethylene, 5 parts of nano silica gel parts, 80 parts of polyvinyl chloride resin, 11 parts of light calcium carbonate, 8 parts of calcium stearate, 4 parts of diallyl phthalate, 2 parts of MBS resin, 1 part of silicon nitride nanoparticles, 4 parts of boron fiber parts, 1 part of antifungal agent, 1 part of heat stabilizer, 5 parts of plasticizer, the preparation process of the PVC material includes the following steps:

[0045] Step 1. Combine chlorinated polyethylene, nano silica gel, polyvinyl chloride resin, light calcium carbonate, calcium stearate, silicon nitride nanoparticles, MBS resin, boron fiber, mildew inhibitor, heat stabilizer, plasticizer Mix and stir evenly in the mixer according to a certain proportion, the stirring speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com