Discharge and mining control method and device of exposing combination development coal-bed gas well upper production layer

A technology for coalbed methane wells and control methods, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

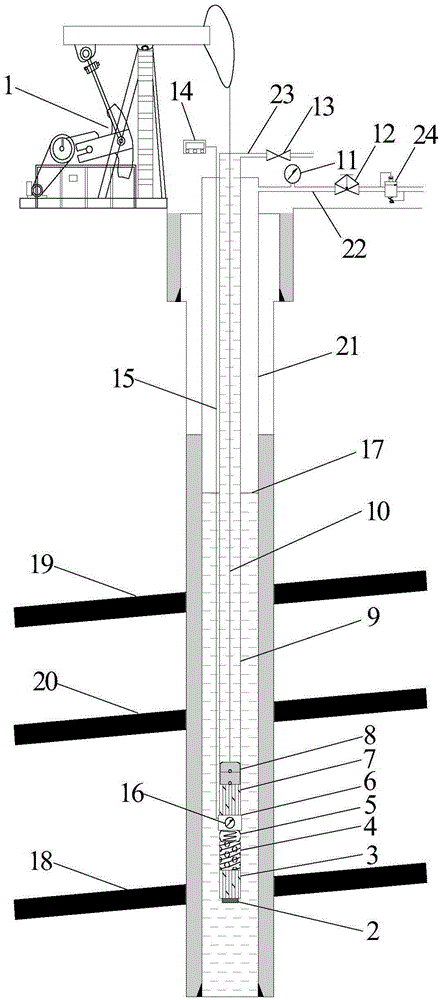

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and a coalbed methane well in Liupanshui Coalfield, Guizhou Province as an example, but the implementation scope of the present invention is not limited.

[0022] In the work area, select a ground location with suitable terrain and geological conditions as the well site, and construct vertical coalbed methane wells or directional wells with a maximum well deviation of less than 35°. Coalbed methane well tool "two opening structure", one opening diameter Drilled to 15m below the bedrock, descending into the outer diameter The surface casing of J55 steel grade is cemented, and the cementing slurry is returned to the surface; Drilling to 50m below the lowest development coal seam 18 is completed, and the outer diameter The production casing of N80 steel grade is cemented, and the cementing slurry is returned to 200m above the uppermost production layer 19 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com