Device for cutting steel through natural gas and oxygen mixed flames

A flame cutting, natural gas technology, applied in gas fuel burners, lighting and heating equipment, combustion methods, etc., can solve the problems of black smoke, large carbon dioxide emissions, high noise, etc., and achieve the effect of advanced technology and fuel saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

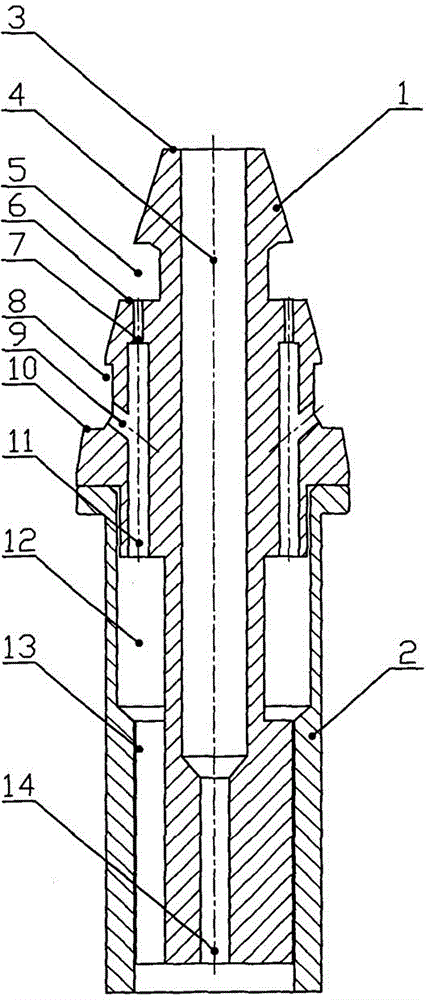

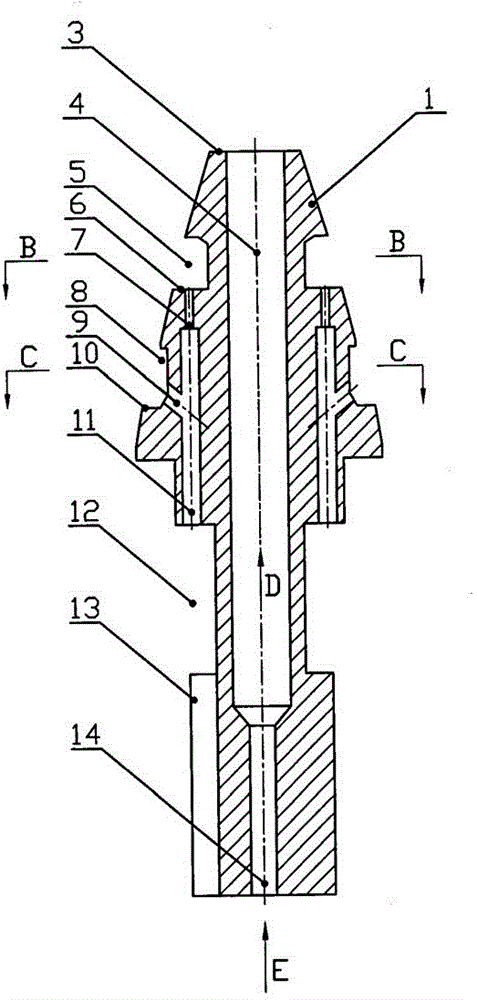

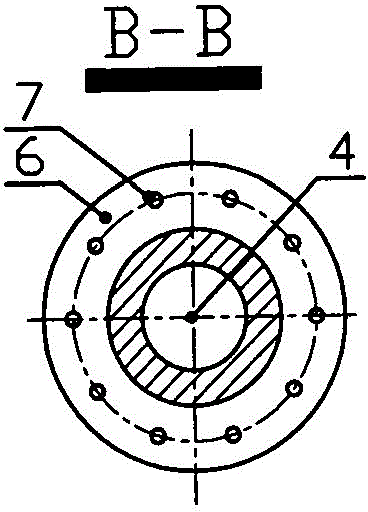

[0016] In order to further illustrate the present invention, further describe below in conjunction with accompanying drawing:

[0017] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, a device for cutting steel using a mixed flame of natural gas and oxygen in the present invention includes a cutting nozzle head 1 and a cutting nozzle cover 2, and the cutting nozzle cover 2 is mounted on the gas outlet section of the cutting nozzle head 1. The middle part of the cutting nozzle head 1 is provided with cutting oxygen holes 4 and 14, and the ratio of the aperture diameter of the cutting oxygen holes 4 in the air inlet section to the cutting oxygen hole 14 in the air outlet section is 1: 0.2 to 0.5; the cutting nozzle head 1 includes an air inlet section, a mixing section and The gas outlet section and the air inlet section are provided with three conical steps, which are the cutting oxygen step 3, the preheating oxygen step 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com