Deep hole bottom windowing etching method of silicon through hole

A technology of through-silicon vias and deep holes, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of low selection ratio and easy short circuit, achieve high mask etching selection ratio, and the method design is simple and reasonable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the method for etching the deep hole bottom of the through-silicon via according to the present invention will be further described in detail through the following examples and in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

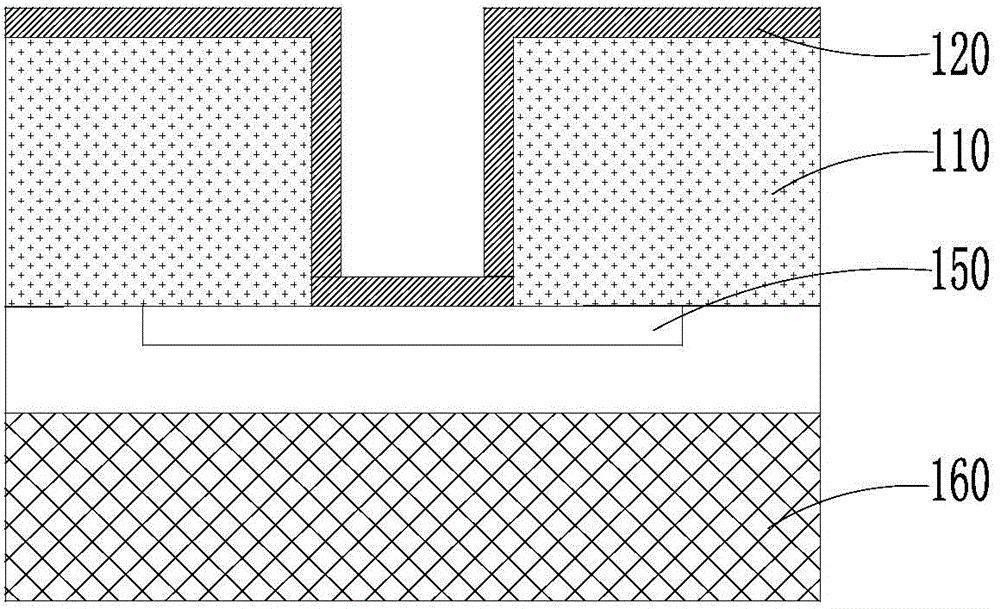

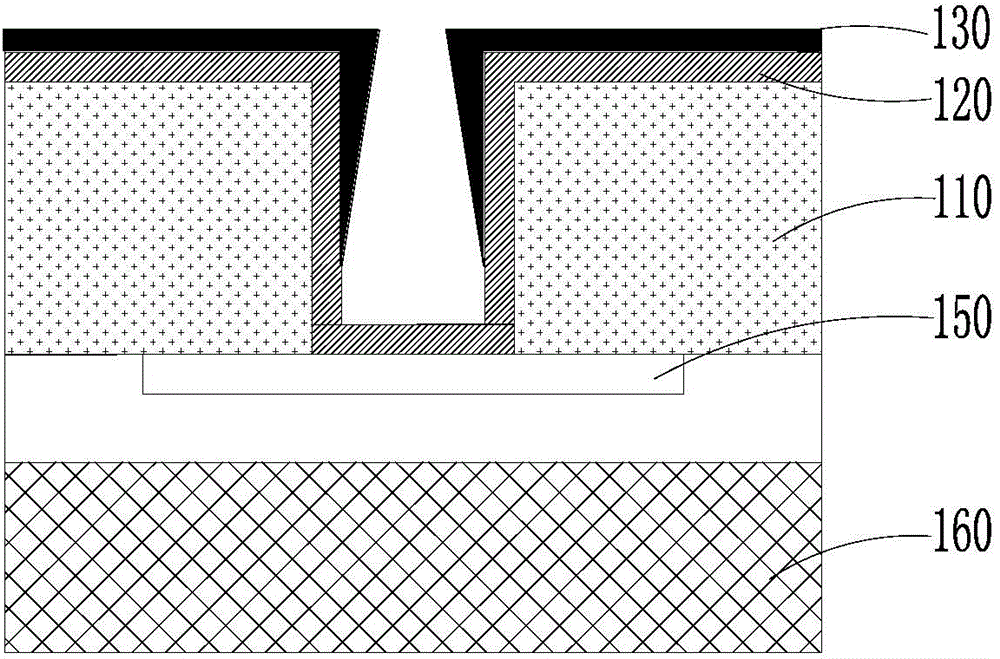

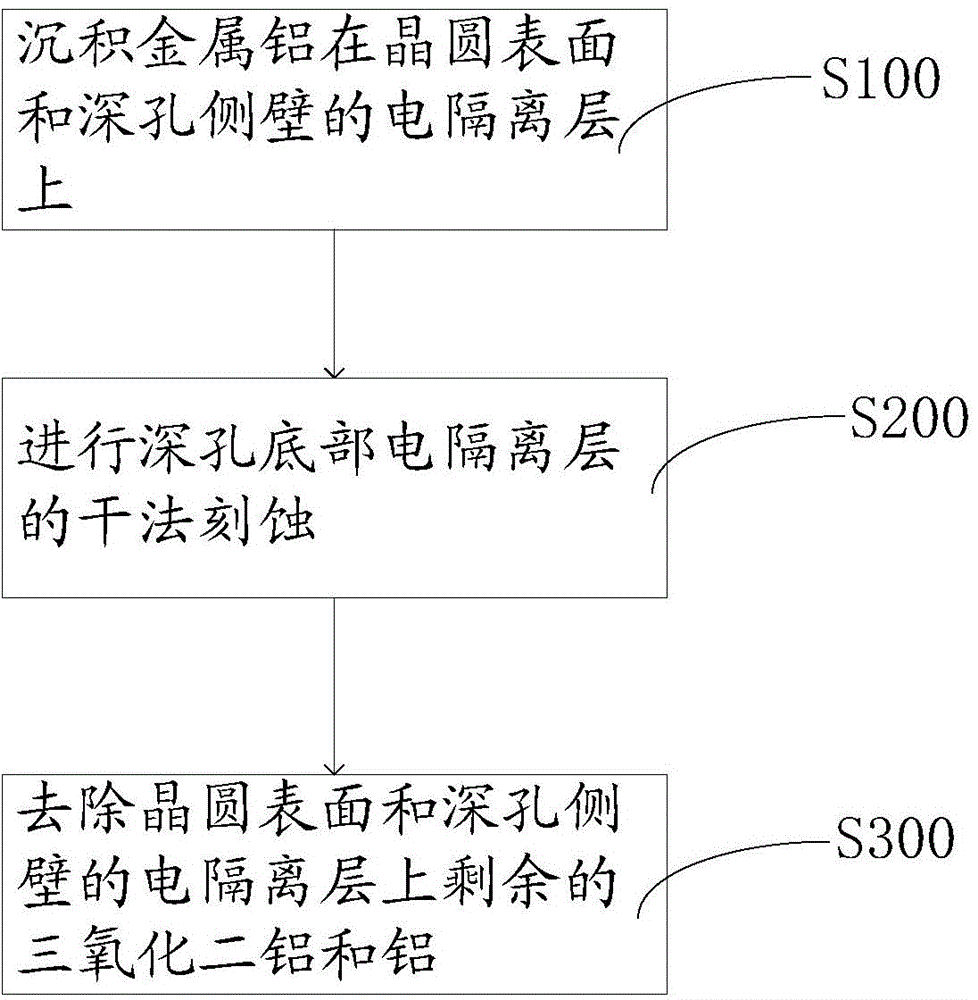

[0033] see Figure 3 to Figure 7 , the etching method for opening a window at the bottom of a deep hole of the through-silicon via of the present invention, comprising the following steps:

[0034] S100, deposit metal aluminum 130 on the surface of the wafer and the electrical isolation layer 120 on the sidewall of the deep hole;

[0035] S200, performing dry etching of the electrical isolation layer 120 at the bottom of the deep hole, including the following two steps:

[0036] S210, oxidation step, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap