Temperature resistant reprocessed cheese and preparing method thereof

A technology for processed cheese and cheese, applied in the field of temperature-resistant processed cheese and its preparation, can solve the problems of short shelf life, precipitation of free fat, etc., and achieve the effects of long shelf life, delicate taste and compact microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

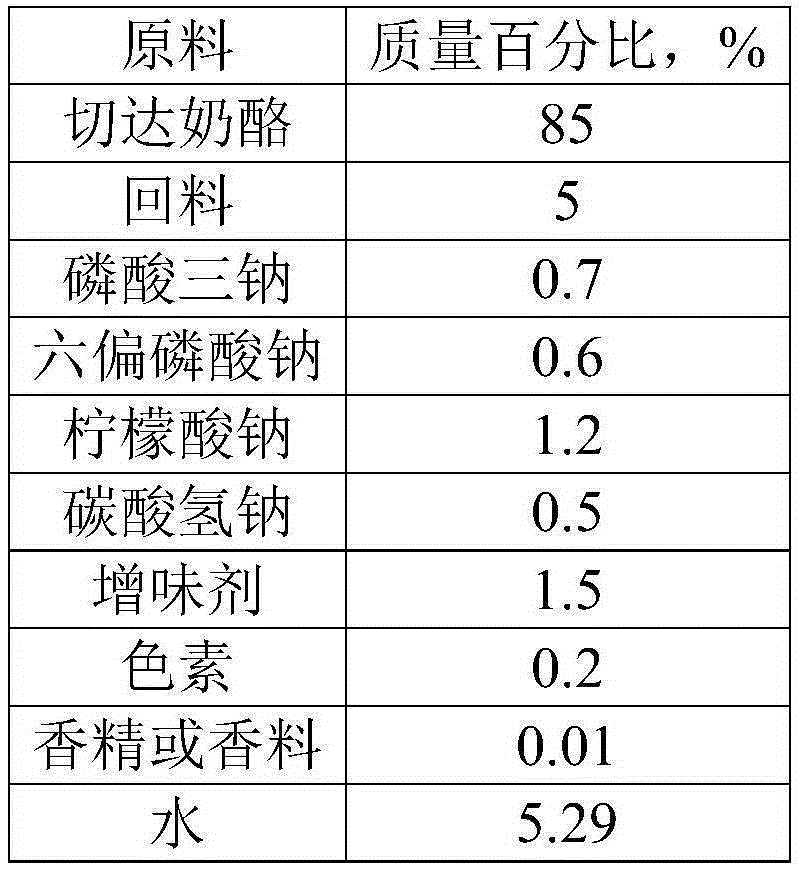

[0043] Table 1

[0044]

[0045]

[0046] A method for preparing heat-resistant processed cheese, comprising the steps of:

[0047] (1) According to the formula in Table 1, put all the raw materials into the cheese melting pot, stir at a speed of 500rpm for 3 minutes, then heat the steam and the jacket to 90°C at the same time, the steam pressure is 3bar, and keep stirring at the same speed for 5 minutes;

[0048] (2) Fill with 5Kg of material / block mould, place in an incubator to cool, cool to 45°C after 1 hour, and process under ultra-high pressure to obtain final product;

[0049] Among them, the pressure of ultra-high pressure treatment is 200 MPa, the number of ultra-high pressure treatment is 3 times, and the time of ultra-high pressure treatment is 10 minutes, 10 minutes and 10 minutes respectively.

Embodiment 2

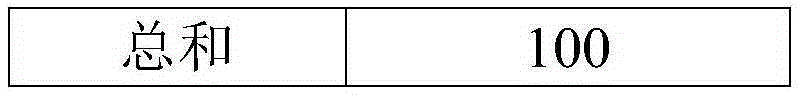

[0051] Table 2

[0052] raw material

Mass percentage, %

gouda cheese

79

Feedback

10

0.6

Hexametaphosphate

0.5

Sodium citrate

1

0.38

1

0.18

flavor or fragrance

0.03

water

7.31

the sum

100

[0053] A method for preparing heat-resistant processed cheese, comprising the steps of:

[0054] (1) According to the formula in Table 2, put all the raw materials into the cheese melting pot, stir at a speed of 300 rpm for 5 minutes, then heat the steam and the jacket to 80°C at the same time, with a steam pressure of 2.5 bar, and keep stirring at the same speed for 7 minutes;

[0055] (2) Fill with 10Kg of material / block mould, place in an incubator to cool, cool to 55°C after 2 hours, and process under high pressure to get final product;

[0056] Among them, the pressure of ultra-high...

Embodiment 3

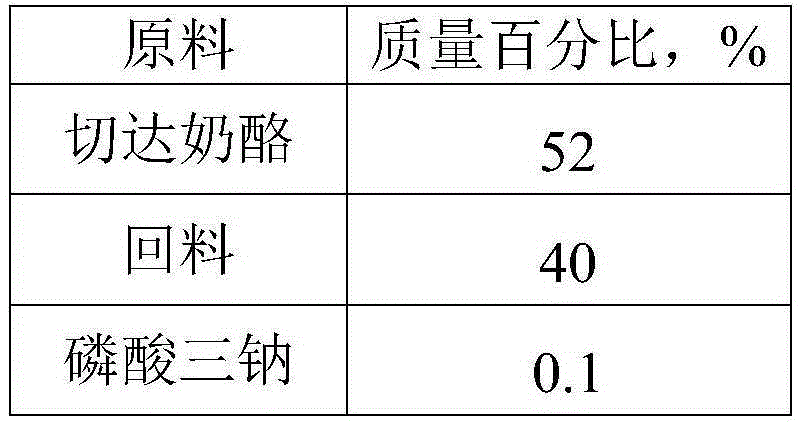

[0058] table 3

[0059] raw material

Mass percentage, %

gruyere cheese

70

Feedback

20

0.5

Hexametaphosphate

0.5

Sodium citrate

0.9

0.35

flavor enhancer

0.8

0.16

flavor or fragrance

0.05

water

6.74

the sum

100

[0060] A method for preparing heat-resistant processed cheese, comprising the steps of:

[0061] (1) Put all the raw materials into the cheese melting pot according to the formula in Table 3, stir at 600rpm for 2 minutes, then heat the steam and the jacket to 85°C at the same time, the steam pressure is 3.5bar, and keep stirring at the same speed for 6 minutes;

[0062] (2) Fill with the filling amount of 15Kg material / block mold, place it in an incubator to cool, cool to 55°C after 3 hours, and process it under ultra-high pressure to get final product;

[0063] Among them, the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com