A powder product forming equipment

A technology for forming equipment and products, which is applied in the field of powder hydraulic presses, can solve problems such as increased production costs, powder leakage, and low efficiency, and achieve the effects of ensuring product quality, improving palletizing efficiency, and reducing defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

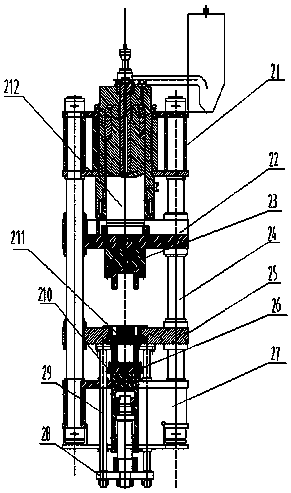

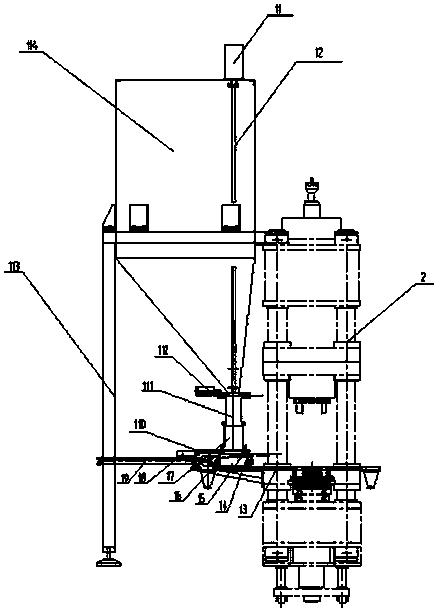

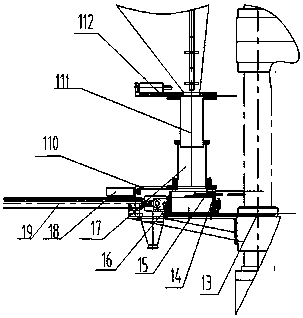

[0027] Such as figure 1 , figure 2 , image 3 As shown, the present invention discloses a powder product forming equipment, including a hydraulic press body 2, a feeding device and a picking and stacking device,

[0028] The hydraulic machine body 2 includes an upper beam 21, a master cylinder 212, an upper slider 22, a lower slider 25, a top cylinder 210, a lower beam 27 and a connecting upper beam 21, an upper slider 22, a lower slider 25 and The four guide columns 24 at the four corners of the lower beam 27, the upper beam 21 is fixedly equipped with a master cylinder 212, the master cylinder 212 is fixedly connected with the upper slider 22 sliding up and down on the guide columns 24 through the piston rod, and the bottom of the upper slider 22 There is an upper punch 23 on the end face, and a top cylinder 210 is fixedly installed on the lower beam 27; a lower punch 26 is arranged on the top end face of the top cylinder 210, and a vertically downward piston rod is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com