Sterile pipe connecting machine

A technology of taking over machine and welding, applied in metal processing and other directions, can solve the problems of high price, complex structure and high price of consumables, and achieve the effect of low price, strong function and superior performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the content of the present invention will be further described:

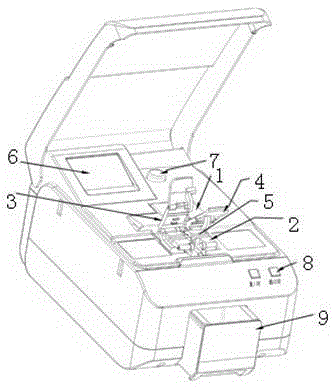

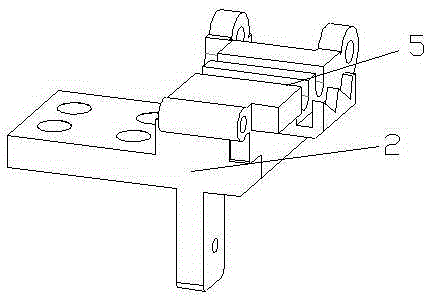

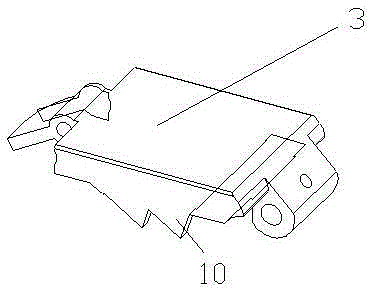

[0013] As shown in the figure is a schematic diagram of the structure of the aseptic tube receiver, including knife box 1, catheter holder 2, left catheter pressure plate 3, right catheter pressure plate 4, catheter groove 5, display screen 6, knife box button 7, start button 8, waste film Box 9 and pressure tube teeth 10.

[0014] The specific operation process is as follows:

[0015] 1. Place the original blood bag or plasma bag on the blood bag holder on the right side of the machine, and press the catheter into the upper catheter groove.

[0016] 2. Place the washing solution bag, white blood cell filter bag or virus inactivated blood bag on the blood bag holder on the left side of the machine, and press the catheter into the lower catheter groove.

[0017] 3. Press down the left conduit pressure plate and the right conduit press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com